Method for preparing oil-carrying crystal gum and application thereof

A crystal gel and grease technology, which is applied in the field of preparing oil-carrying crystal gel, can solve the problems of increasing production and transportation costs, limited emulsion, and increasing transportation costs, and achieves good semi-solid properties, strong temperature stability, and production short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1: A kind of method for preparing oil-carrying crystal glue

[0051] Weigh a certain amount of hydroxypropyl methylcellulose with interface activity and dissolve it in hot water at 75 ° C. The combined ratio of hydroxypropyl methylcellulose and water is 1.6:98.4wt%, and weigh 0.6wt% Xanthan gum was dissolved in 99.4wt% water, and the above two solutions were mixed at a mass ratio of 1:1 to obtain a mixed solution, and the mixed solution was whipped and inflated for 5 minutes at a speed of 10,000 rpm using a high-speed disperser to obtain a water foam. The foam was placed in a low-temperature environment of -20°C for 24 hours, and then placed in a freeze dryer for freeze-vacuum drying for 24 hours after freezing to obtain edible and oil-carrying crystal gel.

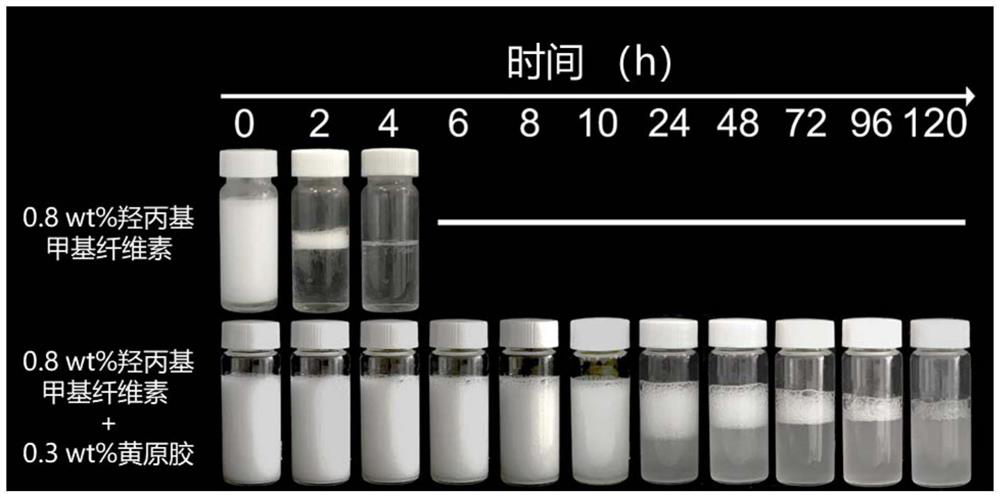

[0052] figure 1 Shown is the influence of the existence of the thickener on the stability of the water foam. In the water foam without adding the xanthan gum thickener, the water foam disappears complet...

Embodiment 2

[0053] Embodiment 2: A kind of method for preparing fat substitute

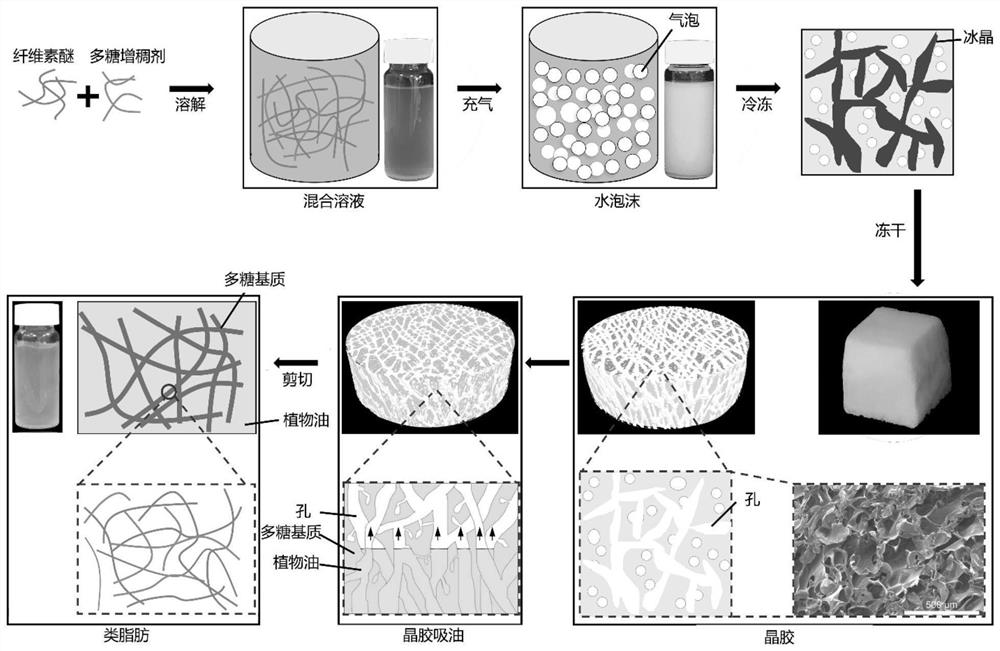

[0054] Place the crystal gel obtained in Example 1 on the soybean oil liquid surface to slowly absorb oil for 30 minutes, let it stand and drain until no more oil drops leak out, and then use a high-speed disperser to high-speed shear the crystal gel after oil absorption for 5 minutes at a rate of 10,000 rpm , to prepare a fat substitute. figure 2 Shown is the preparation process and mechanism diagram of the water foam, crystal gel and subsequent prepared fat substitute in Example 1.

[0055] Use gas chromatography to analyze the fatty acids contained in the prepared fat substitute. The heating program is 0-3min and keep at 130°C, then raise the temperature at 5°C / min to 200°C and keep for 10min, then raise the temperature at 2°C / min to 220°C and keep for 3min ; Split ratio is 20, column flow rate is 1.8mL / min. The composition of fatty acids in soybean oil-containing fat substitutes prepared by hydroxyprop...

Embodiment 3

[0063] Weigh a certain amount of hydroxypropyl methylcellulose with interface activity and dissolve it in hot water at 75°C. The combined ratio of hydroxypropyl methylcellulose and water is 1.6:98.4wt%, 2.4:97.6wt%, 3.2 : 96.8wt%, 4.0: 96.0wt%, 6.0: 94.0wt%, weigh 0.6wt% xanthan gum and dissolve it in 99.4wt% water, mix the above two solutions in a mass ratio of 1:1 to obtain a mixed solution , using a high-speed disperser at a rate of 10,000 rpm to whip and aerate the mixed solution at high speed for 5 minutes to obtain a water foam. The water foam was placed in a low-temperature environment of -20°C for 24 hours, and after freezing, it was placed in a freeze dryer for freeze-vacuum drying for 24 hours to obtain crystals. Glue: place the crystal gel on the soybean oil liquid surface to slowly absorb oil for 30 minutes, let it stand and drain until no more oil drops leak out, and then use a high-speed disperser to high-speed shear the crystal gel after oil absorption for 5 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com