A kind of micro-alloyed molybdenum-ruthenium alloy preparation method

A technology of microalloying and ruthenium alloy, which is applied in the field of metal material processing, to achieve the effects of improving performance stability and life, uniform distribution, and reducing material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

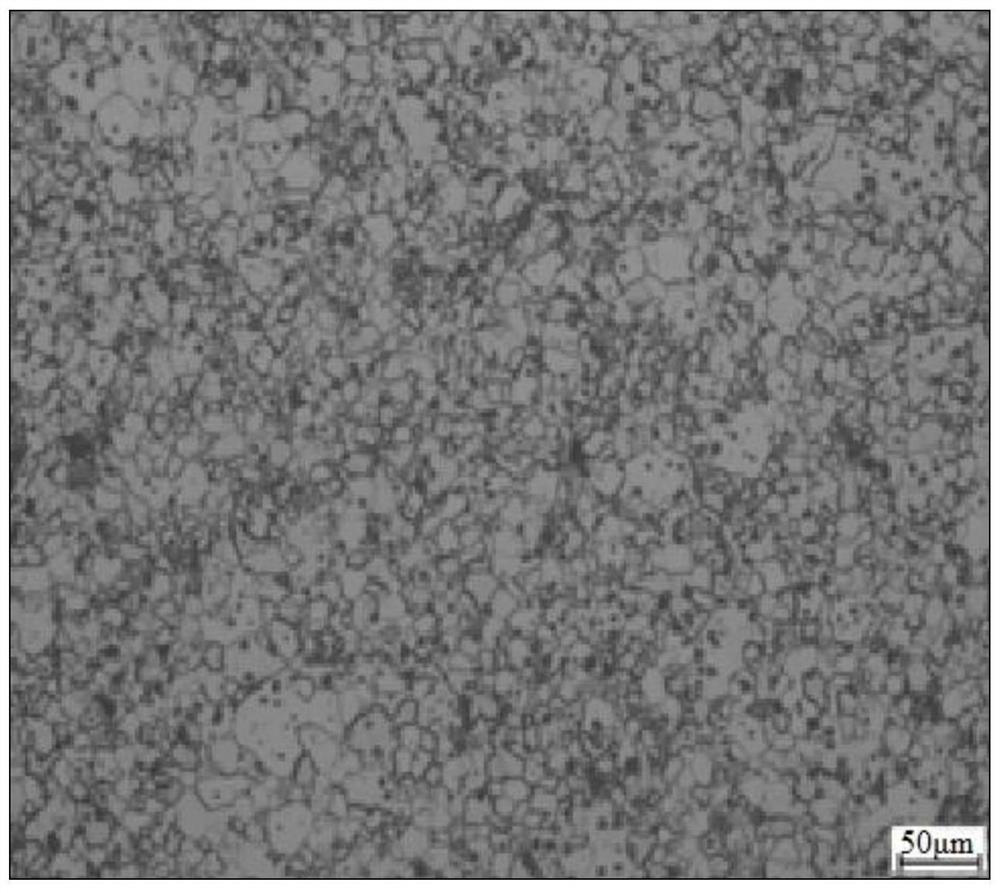

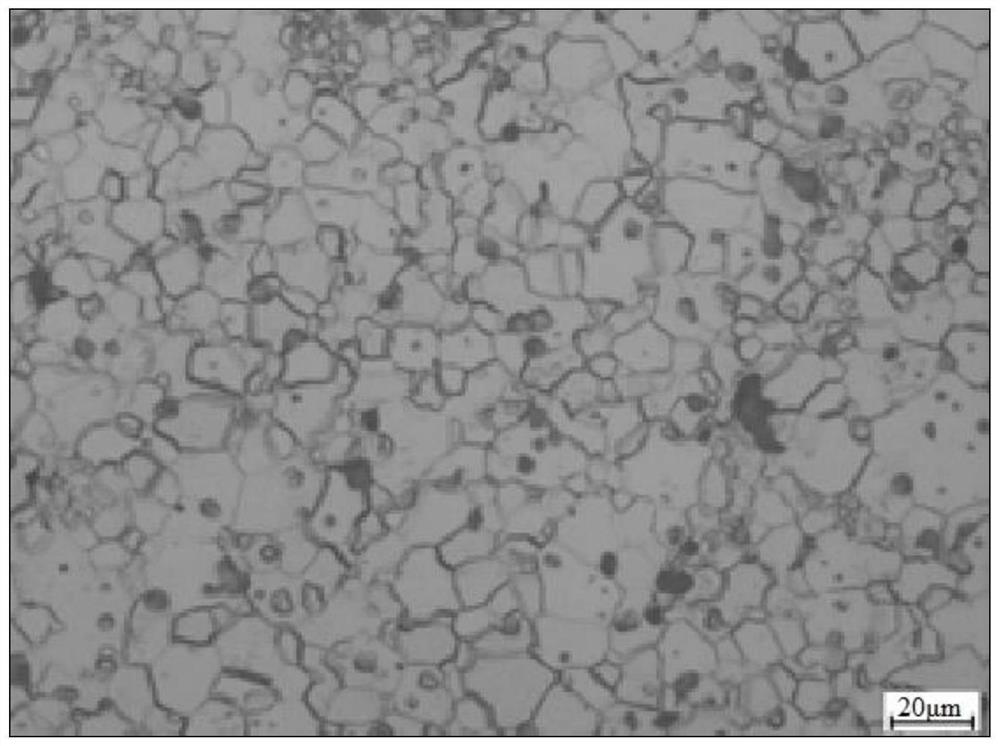

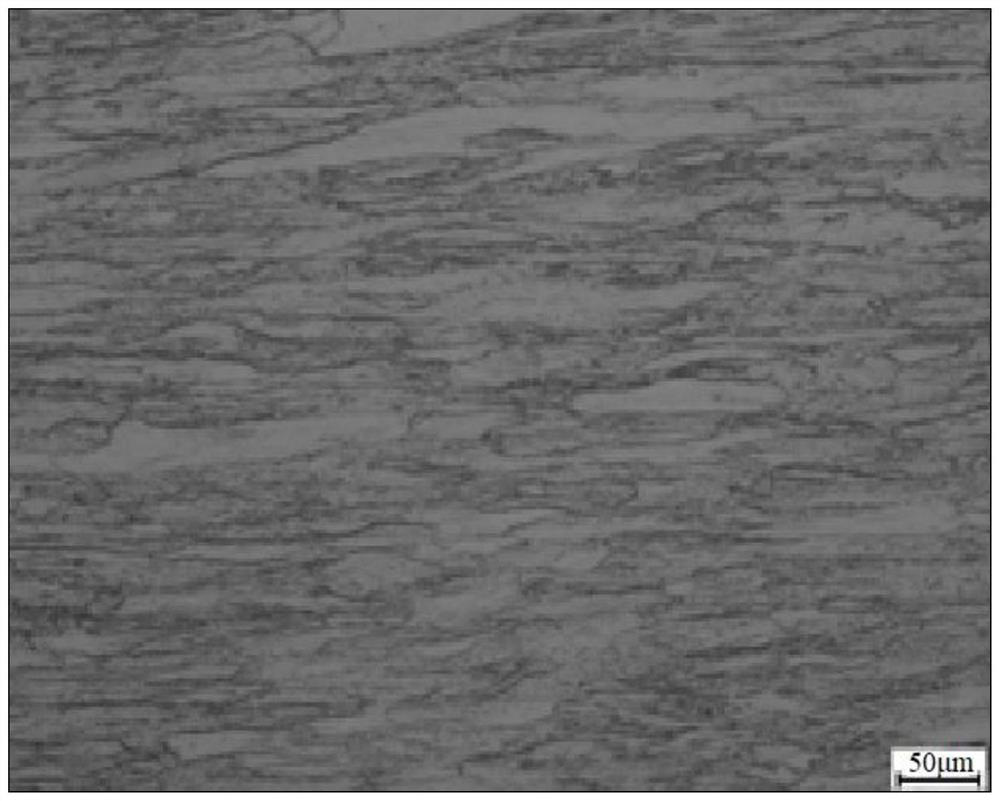

Image

Examples

Embodiment 1

[0034] This embodiment includes the following steps:

[0035] Step 1. Add 0.16kg of ruthenium trichloride hydrate into the beaker, add absolute ethanol and stir until completely dissolved, then add it into 9.94kg of molybdenum powder and stir evenly, and use absolute ethanol to clean the beaker and pour the cleaning solution into Stir evenly in the molybdenum powder, then transfer to a polytetrafluoroethylene mixing tank with a solvent of 20L, and use a three-dimensional powder mixer to mix the powder for 4 hours to obtain a mixed powder;

[0036] The ruthenium element content in the hydrated ruthenium trichloride is 37.5%;

[0037] The average Fischer particle size of the molybdenum powder is 2.5 μm, and the mass purity is 99.97%;

[0038] Step 2. Put the mixed powder obtained in step 1 evenly into 4 molybdenum material boats with a size of 200mm×200mm×30mm (length×width×height), and then perform calcination and reduction under hydrogen atmosphere at 800°C for 3h , to obtai...

Embodiment 2

[0049] This embodiment includes the following steps:

[0050] Step 1. Add 0.10kg of ruthenium trichloride hydrate into the beaker, add absolute ethanol and stir until completely dissolved, then add it into 9.965kg of molybdenum powder and stir evenly, and use absolute ethanol to clean the beaker and pour the cleaning solution into Stir evenly in the molybdenum powder, then transfer to a polytetrafluoroethylene mixing tank with a solvent of 20L, and use a three-dimensional powder mixer to mix the powder for 4 hours to obtain a mixed powder;

[0051] The ruthenium element content in the hydrated ruthenium trichloride is 37.5%;

[0052] The average Fischer particle size of the molybdenum powder is 3.5 μm, and the mass purity is 99.971%;

[0053] Step 2. Put the mixed powder obtained in step 1 evenly into 4 molybdenum material boats with a size of 200mm×200mm×30mm (length×width×height), and then perform calcination and reduction in a hydrogen atmosphere at 950°C for 1.5 h, obtai...

Embodiment 3

[0057] This embodiment includes the following steps:

[0058] Step 1. Add 0.12kg of ruthenium trichloride hydrate into the beaker, add absolute ethanol and stir until completely dissolved, then add it into 9.965kg of molybdenum powder and stir evenly, and use absolute ethanol to clean the beaker and pour the cleaning solution into Stir evenly in the molybdenum powder, then transfer to a polytetrafluoroethylene mixing tank with a solvent of 20L, and use a three-dimensional powder mixer to mix the powder for 4 hours to obtain a mixed powder;

[0059] The ruthenium element content in the hydrated ruthenium trichloride is 37.5%;

[0060] The average Fischer particle size of the molybdenum powder is 3.5 μm, and the mass purity is 99.971%;

[0061] Step 2. Put the mixed powder obtained in step 1 evenly into 4 molybdenum material boats with a size of 200mm×200mm×30mm (length×width×height), and then carry out calcination and reduction in a hydrogen atmosphere at 900°C for 2.5 h, obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com