Multifunctional load type nanometer multilayer composite membrane, and preparation method and application thereof

A nano-multi-layer, load-type technology, applied in the field of membrane separation, can solve the problems of low internal concentration polarized water flux, easy deposition on the membrane surface, and large bending degree of membrane pores, so as to improve the solute retention rate and permeability. The effect of fast passing rate and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

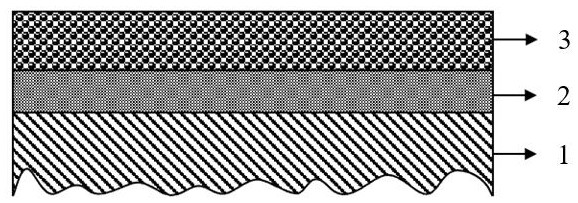

[0025] As another aspect of the technical solution of the present invention, it also relates to a preparation method of a multifunctional supported nano-multilayer composite film, which includes:

[0026] (1) Applying the first mixed reaction system including polydimethylsiloxane prepolymer, curing agent, fluorocarbon material and first solvent to the surface of the substrate to obtain a super-hydrophobic rough substrate;

[0027] (2) reacting the second mixed reaction system comprising polymer resin, vinyl monomer, catechol compound, amine polymer and second solvent to obtain a uniform casting solution, and applying the uniform casting solution to On the superhydrophobic rough substrate obtained in step (1), a polymer microporous support layer is prepared;

[0028] (3) fully contacting the polymer microporous support layer obtained in step (2) with the acid chloride solution to react to form an aminated cross-linked transition layer to obtain an aminated cross-linked transiti...

Embodiment 1

[0083] Mix 2wt% polydimethylsiloxane (PDMS) prepolymer, 0.2wt% hexamethoxymethylmelamine resin, 0.1wt% fluorinated graphite and ethyl acetate, and spray evenly on the surface of the glass plate to obtain superhydrophobic Rough glass plate; add 5wt% polyvinylidene fluoride, 10wt% acrylic acid, 1wt% dopamine, 1wt% polyethyleneimine, 83wt% N,N-dimethylacetamide into the reaction kettle, and react at 25°C for 72h to obtain Uniform casting film solution, which is uniformly scraped on a super-hydrophobic rough glass plate, immersed in water, taken out to obtain a polymer microporous support film; immersed in 0.1wt% trimesoyl chloride n-hexane solution, reacted for 0.5 minutes, Obtain an aminated cross-linked transition layer; immerse in 0.5wt% citric acid, 0.5wt% ferric chloride, 0.1wt% graphite phase nitrogen carbide, 98.9wt% ethylene glycol, and heat in a microwave oven for 0.5 minutes under the condition of 900W , to obtain nano-hybrid multi-skinned layers.

[0084] After testin...

Embodiment 2

[0086]Mix 20wt% polydimethylsiloxane (PDMS) prepolymer, 2wt% hexamethylene diisocyanate trimer, 10wt% fluorinated graphene and 68wt% chloroform, and spray evenly on the surface of the glass plate to obtain Superhydrophobic rough glass plate; add 35wt% polysulfone, 35wt% hydroxyethyl methacrylate, 10wt% tannic acid, 10wt% polyetheramine, 10wt% triethyl phosphate into the reaction kettle, and react at 100°C for 4h, Obtain a uniform casting film solution, scrape it evenly on a super-hydrophobic rough glass plate, immerse it in ethanol, take it out, and obtain a polymer microporous support film; immerse it in the acetone solution of 10wt% terephthaloyl chloride, and react for 10 minutes , to obtain an aminated cross-linked transition layer; immersed in 20wt% citric acid, 10wt% iron sulfate, 5wt% graphite phase nitrogen carbide, and 65wt% water, heated in a microwave oven for 10 minutes under 600W to obtain a nano-hybrid multi-skin layer.

[0087] After testing, when using 1mol / L s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com