Preparation method and application of lithium ion battery positive electrode active material

A cathode active material, lithium-ion battery technology, applied in electrode manufacturing, battery electrode, electrolyte storage battery manufacturing and other directions, can solve the problems of difficult to put into actual production, high cost of preparation methods, inconsistent initial charge and discharge behavior, etc., to achieve reversible oxidation Reduction reaction, the method is simple and fast, and the effect of inhibiting interlayer migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

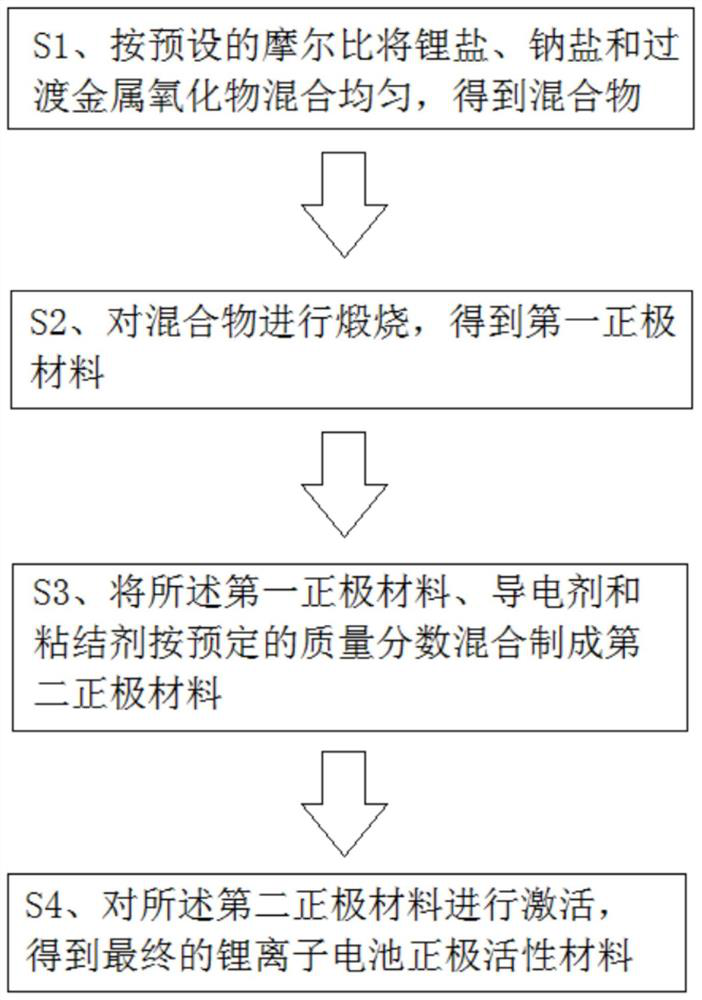

[0040] A preparation method for a positive electrode active material of a lithium ion battery, comprising the following steps:

[0041] (1) Put a certain molar ratio of lithium salts, sodium salts and transition metal oxides in a mortar, add an appropriate amount of acetone or alcohol, and grind evenly until the organic solvent is completely volatilized;

[0042] Lithium salt is lithium hydroxide, lithium oxide or lithium carbonate, etc.; sodium salt is sodium hydroxide, sodium oxide or sodium carbonate, etc.; transition metal oxide is one or more of manganese oxide, nickel oxide and cobalt oxide; lithium The molar ratio of salt, sodium salt and transition metal oxide is (0.1~0.4):(0.5~1):(0.6~0.9);

[0043] (2) Collect the uniformly ground mixture in a crucible, calcinate it in a muffle furnace with a certain sintering system, and then cool it to room temperature to obtain the final product;

[0044] The sintering system is specifically calcined at 450-600°C for 4-8 hours, a...

Embodiment 1

[0051] Embodiment 1: a method for realizing the reversible redox of lithium-ion battery cathode material anion, comprising the following steps:

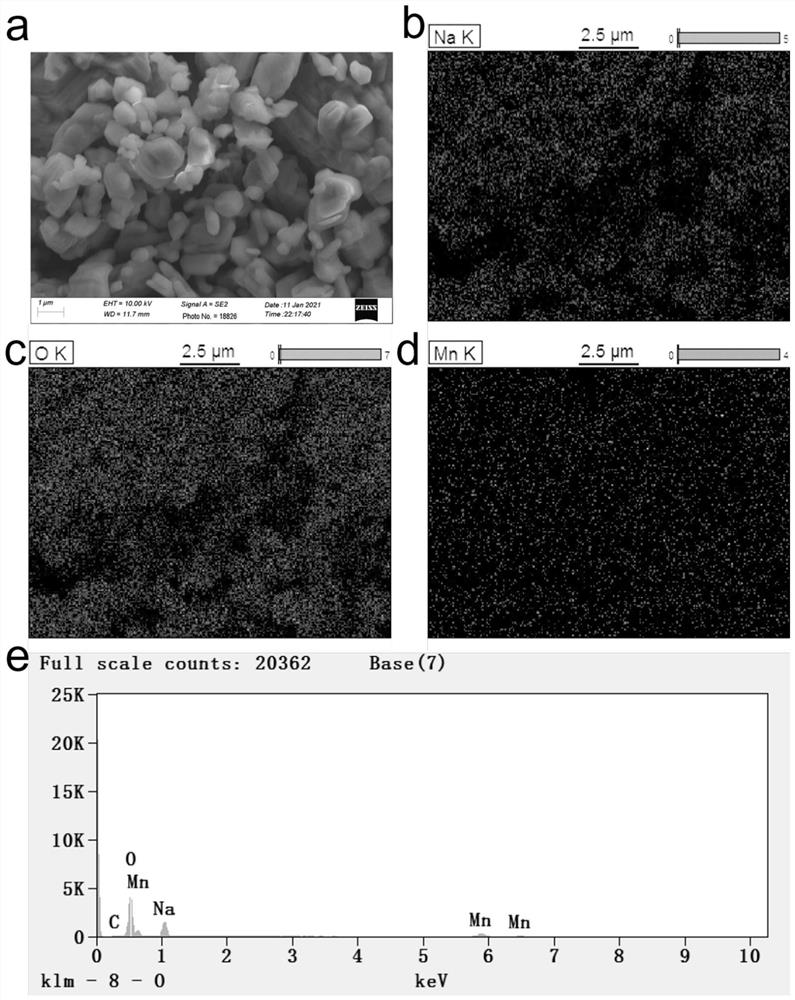

[0052] (1) Put lithium hydroxide, sodium carbonate, and manganese dioxide with a molar ratio of 0.2:0.6:0.8 in a mortar, add an appropriate amount of acetone or alcohol, and grind evenly until the organic solvent evaporates completely;

[0053] (2) The homogeneously ground mixture was collected in a crucible, heated in a muffle furnace at 450° C. for 5 h, then calcined at 800° C. for 12 h, and then cooled to room temperature.

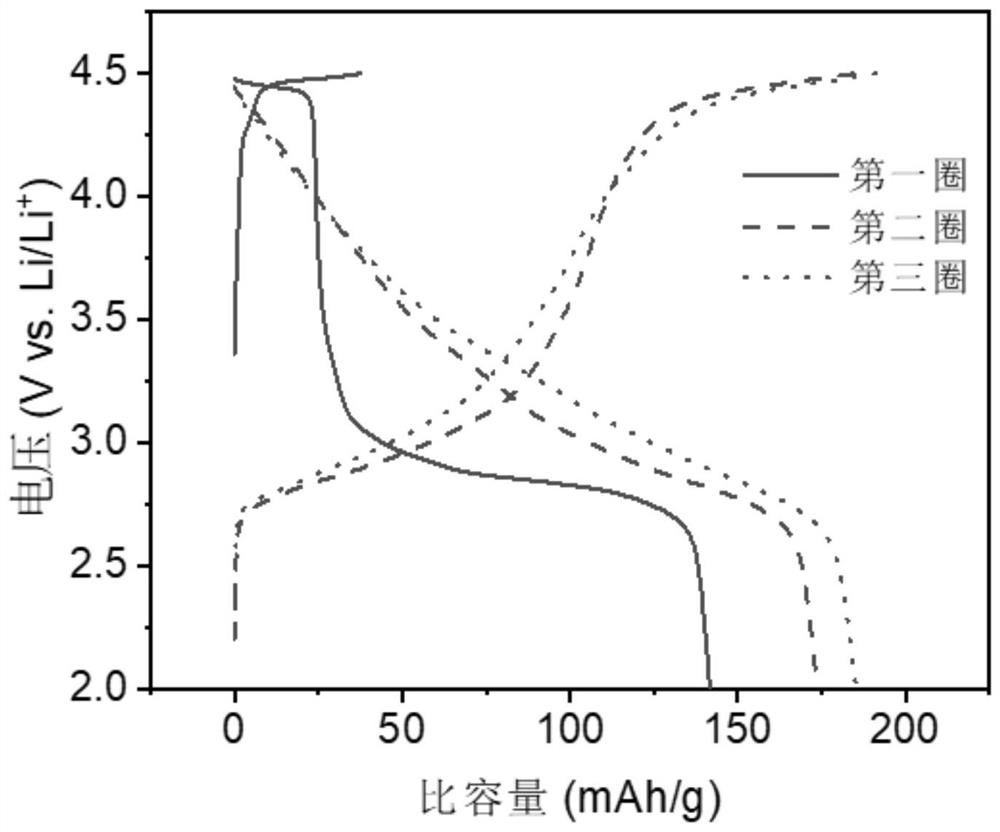

[0054] (3) The positive electrode material, Super P, and PVDF are made into lithium-ion battery positive pole pieces with a mass fraction of 75%: 15%: 10%, and assembled into a button battery, wherein the electrolyte is lithium-ion battery electrolyte ( 1mol / L LiPF 6 Dissolved in the EC / DMC solution with a volume ratio of 1:1), the negative electrode is lithium metal;

[0055] (4) After the assembled battery...

Embodiment 2

[0056] Embodiment 2: a method for realizing the reversible redox of lithium-ion battery cathode material anions, comprising the following steps:

[0057] (1) Put lithium hydroxide, sodium carbonate, and manganese dioxide with a molar ratio of 0.33:1:0.66 in a mortar, add an appropriate amount of acetone or alcohol, and grind evenly until the organic solvent evaporates completely;

[0058] (2) The homogeneously ground mixture was collected in a crucible, heated in a muffle furnace at 450° C. for 5 h, then calcined at 850° C. for 12 h, and then cooled to room temperature.

[0059] (3) The positive electrode material, Super P, and PVDF are made into lithium-ion battery positive pole pieces with a mass fraction of 75%: 15%: 10%, and assembled into a button battery, wherein the electrolyte is lithium-ion battery electrolyte ( 1mol / L LiPF 6 Dissolved in the EC / DMC solution with a volume ratio of 1:1), the negative electrode is lithium metal;

[0060] (4) After the assembled batter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com