Coupling method of mto process and naphtha steam cracking process for producing ethylene

A technology for producing ethylene and naphtha by cracking, which is applied in ethylene production, hydrocarbon cracking to produce hydrocarbons, and hydrocarbon production from oxygen-containing organic compounds, etc., can solve the problems of unreasonable process design, high operating costs, large investment, etc. The effect of engineering investment, reduction of operating costs, and reasonable process design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

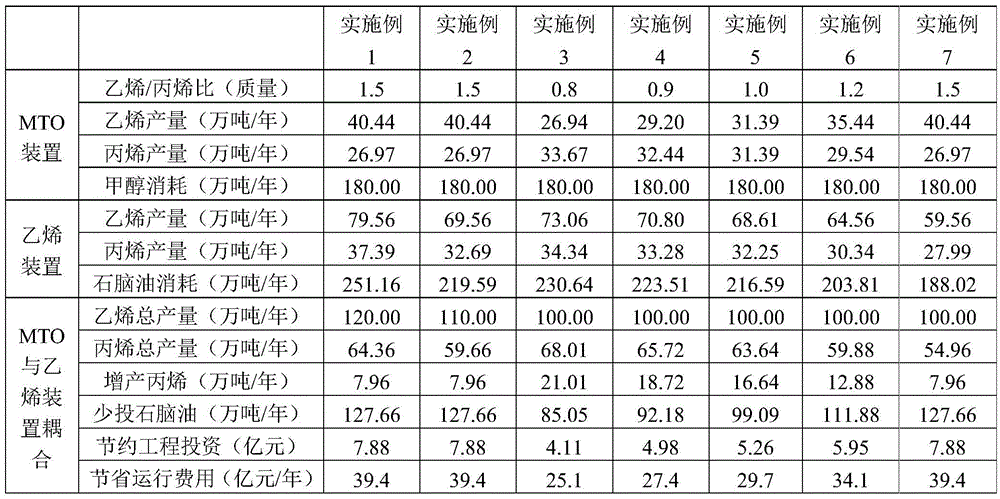

Embodiment 1

[0022] The naphtha steam cracking ethylene unit adopts the pre-deethanization process, the ethylene production capacity is 1.2 million tons / year, the mass ratio of propylene to ethylene in the cracking gas is 0.47, and the methanol treatment scale of the newly added MTO unit is 1.8 million tons / year In 2009, the mass ratio of ethylene to propylene in MTO product gas was 1.5. Using the coupling method of the present invention, the operating conditions of the rough separation tower are: temperature is -10°C, pressure is 1.5MPaG. The obtained polymerization-grade ethylene has a purity of ≥99.95 mol%, and the polymerization-grade propylene has a purity of ≥99.6 mol%. The output distribution data of ethylene and propylene are shown in Table 1. Compared with Comparative Example 1, the input of naphtha is reduced by 1.2766 million tons / year, the production of propylene is increased by 79,600 tons / year, the investment of MTO plant project is saved by 788 million yuan, and the price di...

Embodiment 2

[0026] The naphtha steam cracking ethylene unit adopts the pre-deethanization process, the ethylene production capacity is 1.1 million tons / year, the mass ratio of propylene to ethylene in the cracking gas is 0.47, and the methanol treatment scale of the newly added MTO unit is 1.8 million tons / year In 2009, the mass ratio of ethylene to propylene in MTO product gas was 1.5. Using the coupling method of the present invention, the operating conditions of the rough separation tower are: temperature is -10°C, pressure is 1.5MPaG. The obtained polymerization-grade ethylene has a purity of ≥99.95 mol%, and the polymerization-grade propylene has a purity of ≥99.6 mol%. The output distribution data of ethylene and propylene are shown in Table 1. Compared with Comparative Example 2, the input of naphtha is reduced by 1.2766 million tons / year, the production of propylene is increased by 79,600 tons / year, the investment of MTO plant project is saved by 788 million yuan, and the price di...

Embodiment 3

[0030] The naphtha steam cracking ethylene unit adopts the pre-deethanization process, the ethylene production capacity is 1 million tons / year, the mass ratio of propylene to ethylene in the cracking gas is 0.47, and the methanol treatment scale of the newly added MTO unit is 1.8 million tons / year In 2009, the mass ratio of ethylene to propylene in MTO product gas was 0.8. Using the coupling method described in the present invention, the operating conditions of the crude separation tower are: temperature is -20°C, and pressure is 0.6MPaG. The obtained polymerization-grade ethylene has a purity of ≥99.95 mol%, and the polymerization-grade propylene has a purity of ≥99.6 mol%. The output distribution data of ethylene and propylene are shown in Table 1. Compared with Comparative Example 3, the input of naphtha is reduced by 850,500 tons / year, the production of propylene is increased by 210,100 tons / year, the investment of MTO plant project is saved by 411 million yuan, and the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com