High-thermal-conductivity corrosion-resistant electrical steel self-bonding coating and preparation method thereof

A high thermal conductivity, corrosion-resistant technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of deteriorating magnetic properties of iron cores, easy to generate noise, poor corrosion resistance of coatings, etc., and achieve good thermal conductivity. performance and insulating properties, improved corrosion resistance, effect of good insulating properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

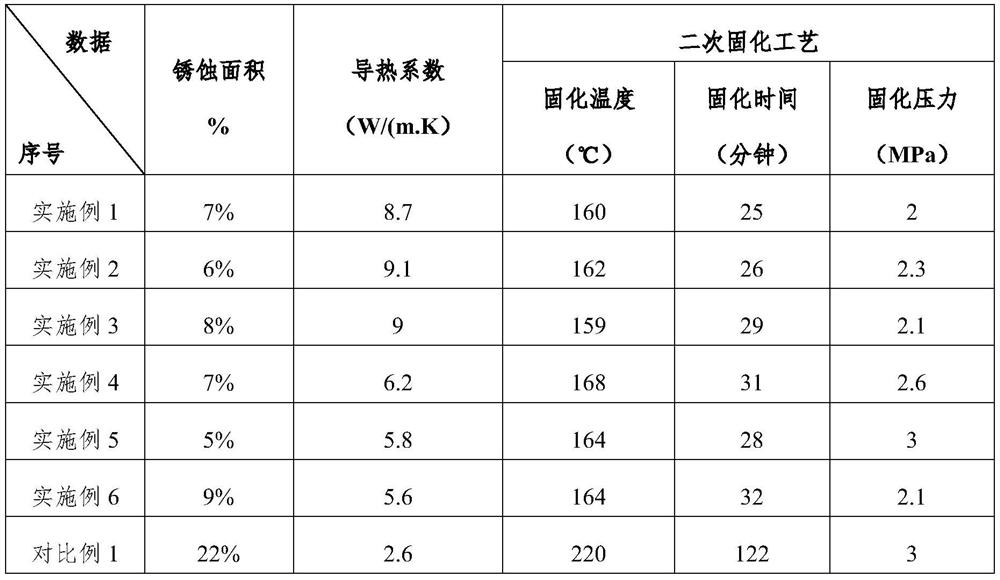

Examples

Embodiment 1

[0033] A high thermal conductivity corrosion-resistant electrical steel self-adhesive coating, the preparation method of which is:

[0034] In the electric heating high-speed dispersion kettle, 10% propylene glycol methyl ether, 0.5% isooctyl phosphate, 4% F44 novolak epoxy resin, 35% E12 bisphenol A epoxy resin were added sequentially according to the mass percentage under the stirring state, Then heat it to 150°C and keep it warm for 60 minutes; cool the material in the electric heating high-speed dispersion kettle to 70°C, add 5% emulsifier Reactsurf 0092, and stir for 30 minutes; At the same time of high-speed dispersion, 22.64% pure water was added dropwise at a constant speed for 120 minutes; after the pure water was added dropwise, continued high-speed dispersion for 45 minutes; the material in the electric heating high-speed dispersion kettle was cooled to 35°C, and the coating "Group A" was prepared At room temperature, add 5.66% pure water into the grinder, then add ...

Embodiment 2

[0037] A high thermal conductivity corrosion-resistant electrical steel self-adhesive coating, the preparation method of which is:

[0038] In the electric heating high-speed dispersion kettle, add 5% propylene glycol methyl ether, 0.2% isooctyl phosphate, 8% F44 novolac epoxy resin, 25% E12 bisphenol A epoxy resin in sequence according to the mass percentage under the stirring state, Then heat to 200°C and keep it warm for 90 minutes; cool the material in the electric heating high-speed dispersion kettle to 90°C, add 8% emulsifier Reactsurf 0092, and stir for 10 minutes; While dispersing at a high speed, add 38.88% pure water dropwise at a constant speed for 150 minutes; after adding the pure water dropwise, continue to disperse at a high speed for 30 minutes; cool the material in the electric heating high-speed dispersing kettle to 20°C, and then make the coating "Group A" At room temperature, add 9.72% pure water into the grinder, then add 0.3% alcohol amine chelated titana...

Embodiment 3

[0041] A high thermal conductivity corrosion-resistant electrical steel self-adhesive coating, the preparation method of which is:

[0042] In the electric heating high-speed dispersion kettle, add 8% propylene glycol methyl ether, 0.3% isooctyl phosphate, 6% F44 novolac epoxy resin, 30% E12 bisphenol A epoxy resin in sequence according to the mass percentage under the stirring state, Then heat to 180°C and keep it warm for 70 minutes; cool the material in the electric heating high-speed dispersion kettle to 80°C, add 6% emulsifier Reactsurf 0092, and stir for 20 minutes; While dispersing at a high speed, add 29.08% pure water dropwise at a constant speed for 130 minutes; after adding the pure water dropwise, continue to disperse at a high speed for 30 minutes; cool the material in the kettle to 25°C to make the coating "Component A"; normal temperature Next, add 7.27% pure water into the grinder, then add 0.25% alcohol amine chelated titanate, 10% boron nitride fiber, 0.6% al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com