X-ray exposure device

An exposure device and X-ray technology, which are applied in photoplate-making process exposure devices, microlithography exposure equipment, optics, etc., can solve the problem of low accuracy of overlay patterns, achieve enhanced stability, overcome time-consuming, and improve accuracy sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

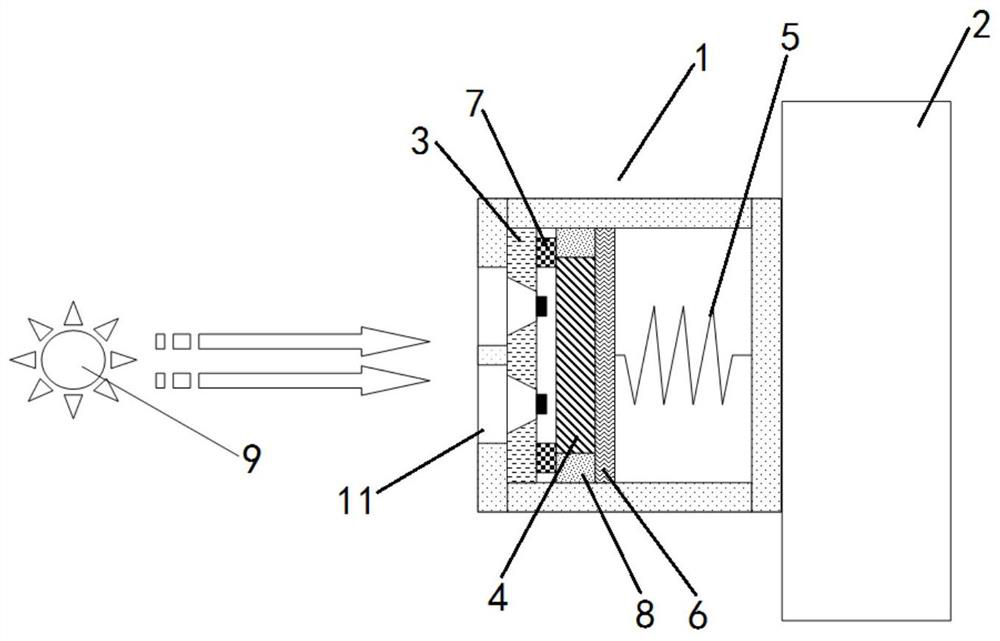

[0036] An X-ray exposure device, such as figure 1 As shown, including a sleeve 1 and a mobile worktable 2, optical devices such as a reticle 3 and a photoresist substrate 4 are fixed in the sleeve 1, and X-rays emitted by an X-ray light source 9 pass through the light entrance opened on the sleeve 1 11 Enter the sleeve 1, the sleeve 1 is connected with the mobile worktable 2, the mobile worktable 2 is an X-Y worktable, which can improve the accuracy of the mobile exposure, and by controlling the X-Y worktable, the exposure area of the mobile exposure can be increased, thereby improving the X-ray exposure. Exposure efficiency, and the whole device is placed in a large exposure chamber filled with helium, which ensures that the dose of X-rays will not attenuate. The wavelength range of the X-rays emitted by the X-ray light source 9 is 0.15-0.95 nm, and the photon energy of the X-rays is greater than 1.3 keV.

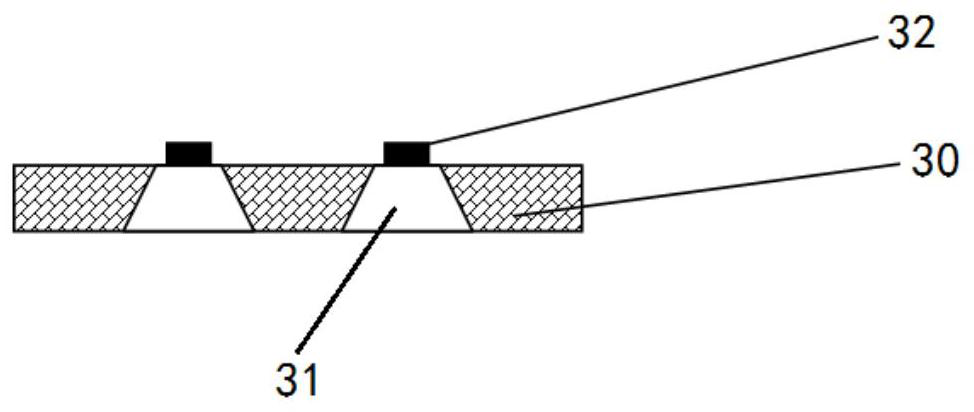

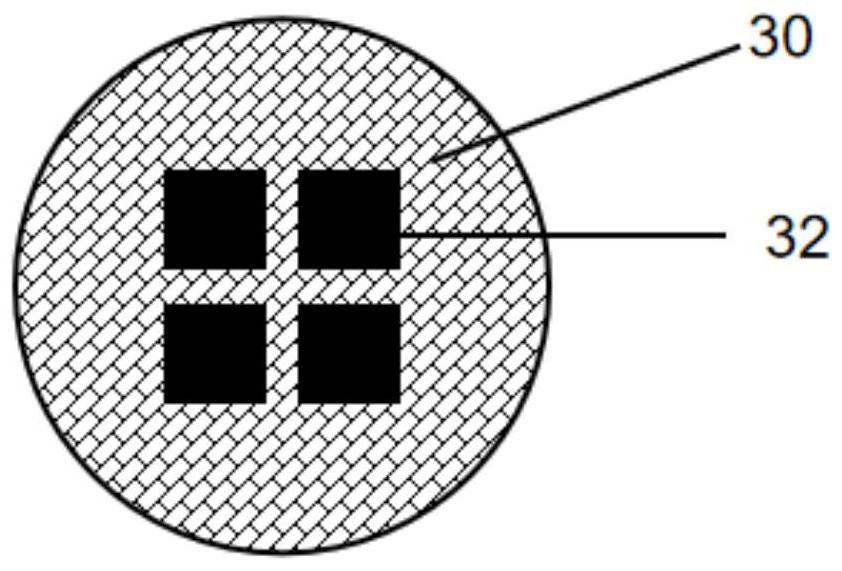

[0037] A reticle 3 , a spacer 7 , a photoresist substrate 4 , a ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com