Anti-scratch iron-based surfacing material and preparation method thereof

A surfacing material and anti-scratch technology, which is applied in the field of surface engineering and surface wear resistance, can solve the problems of inapplicability to on-site construction, etc., and achieve the effects of good surfacing welding process, improved martensitic transformation temperature and good plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

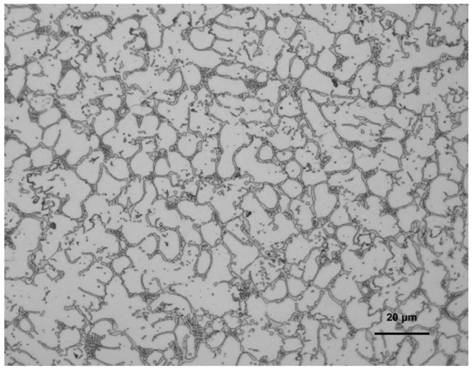

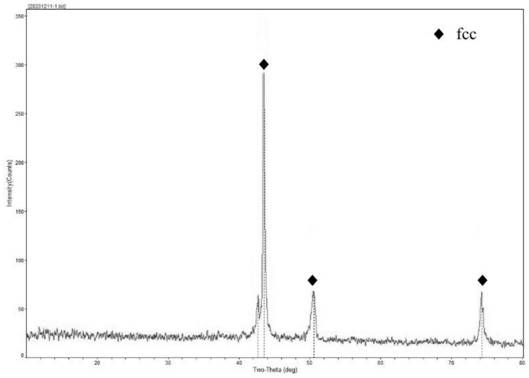

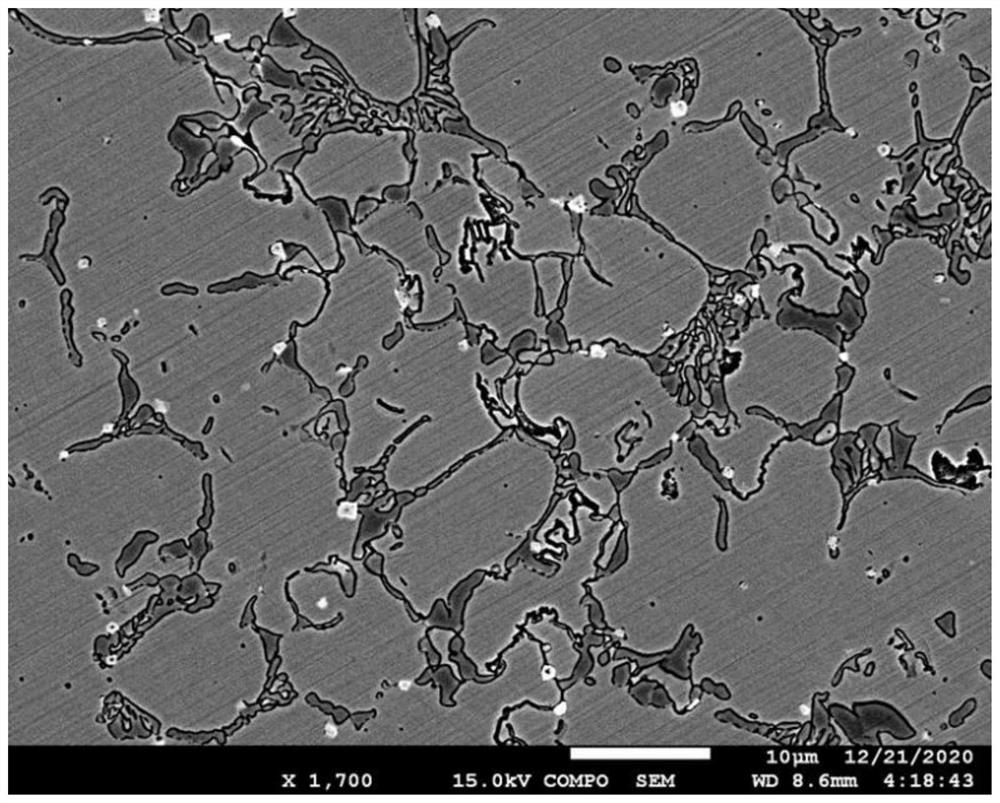

Image

Examples

specific Embodiment

[0033] 1. A nitrogen-containing iron-based scratch-resistant surfacing flux-cored welding wire, the wire composition weight ratio is: Cr: 22wt.%; Ni: 7.5wt.%; C: 1.2wt%; N: 0.1wt.%; Mn: 5wt.%; Si: 3.3wt.%; Mo: 2wt.%; Nb: 0.8wt.%; Fe balance. The flux-cored wire is partially filled with powder, and polyvinyl alcohol solution (pva) with a volume ratio concentration of 5% is used for agglomeration at a mass ratio of solution to powder of 1:10, and then the vacuum tube furnace is kept at 500°C for 2 hours for debinding , Use a sieve to select powder with a particle size of 100-200 mesh, put the mixed powder into a powder mixer and mix for 40 minutes to obtain the required powder, the flux core accounts for 30% of the total mass of the welding wire. The parameters of the plasma arc surfacing welding process are: plasma arc current 80A, stable arc current 50A, voltage 30V, wire feeding speed: 1000mm / min, and the plasma gas is output after a volume ratio of 20% nitrogen and 80% argon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com