Monatomic metal-molybdenum sulfide nano-composite as well as preparation method and application thereof

A nano-composite, molybdenum sulfide technology, applied in the field of electrocatalysis, can solve the problems of inability to realize electrochemical deposition, expensive catalysts, limited wide application, etc., to achieve improved catalytic activity and stability, reduced catalyst costs, and easy promotion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

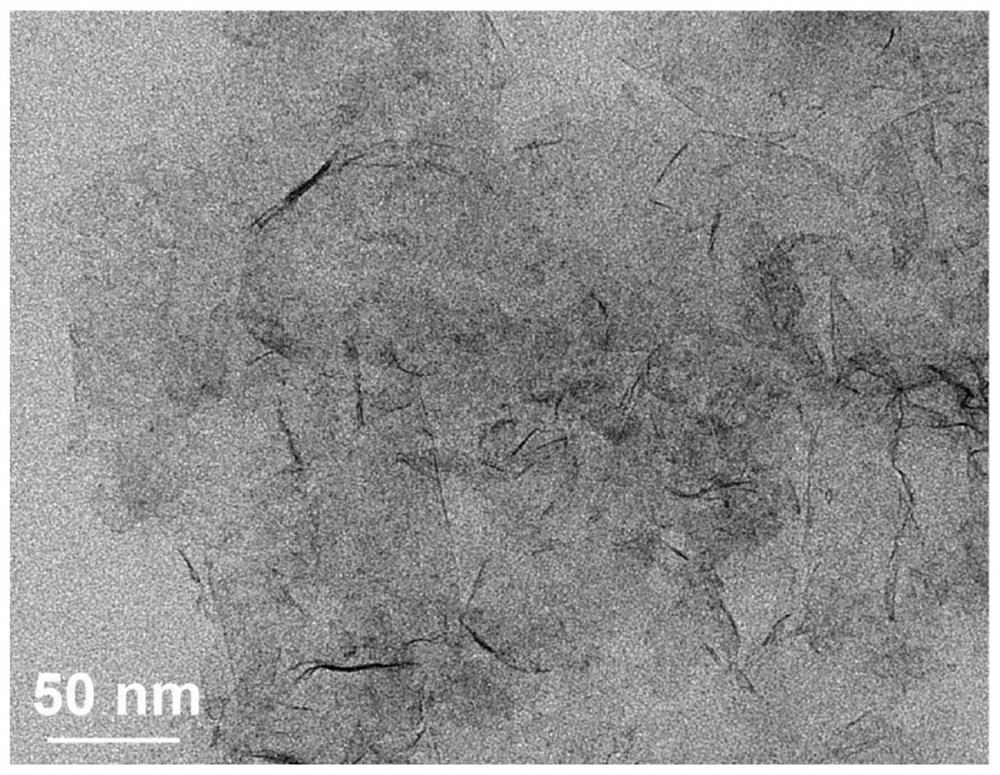

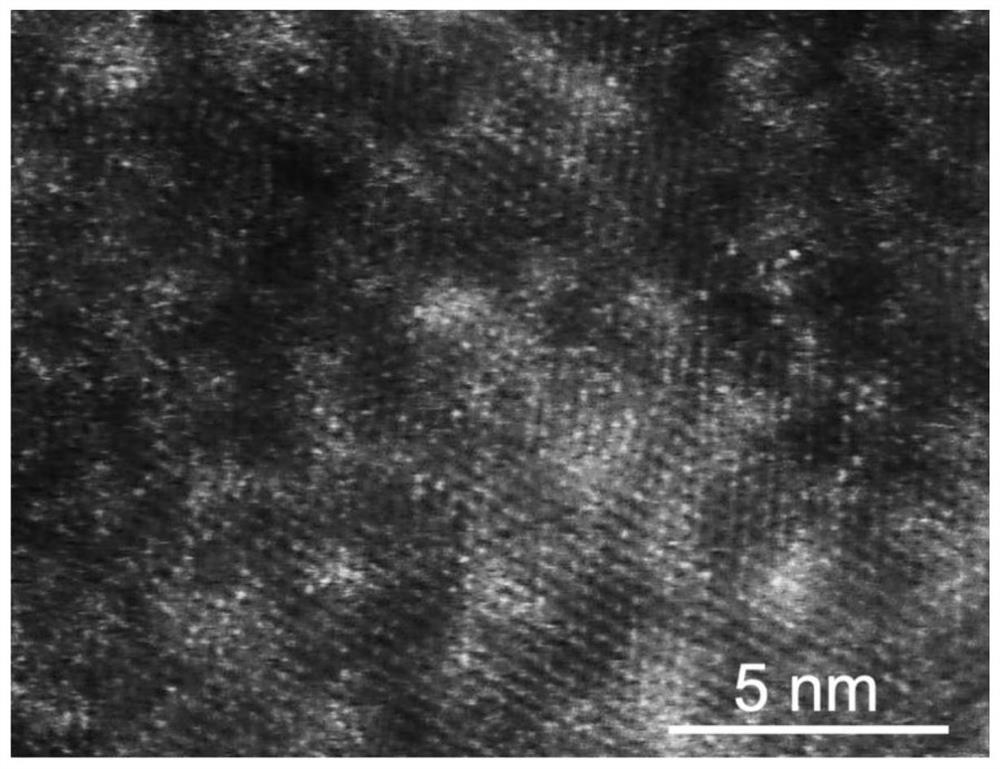

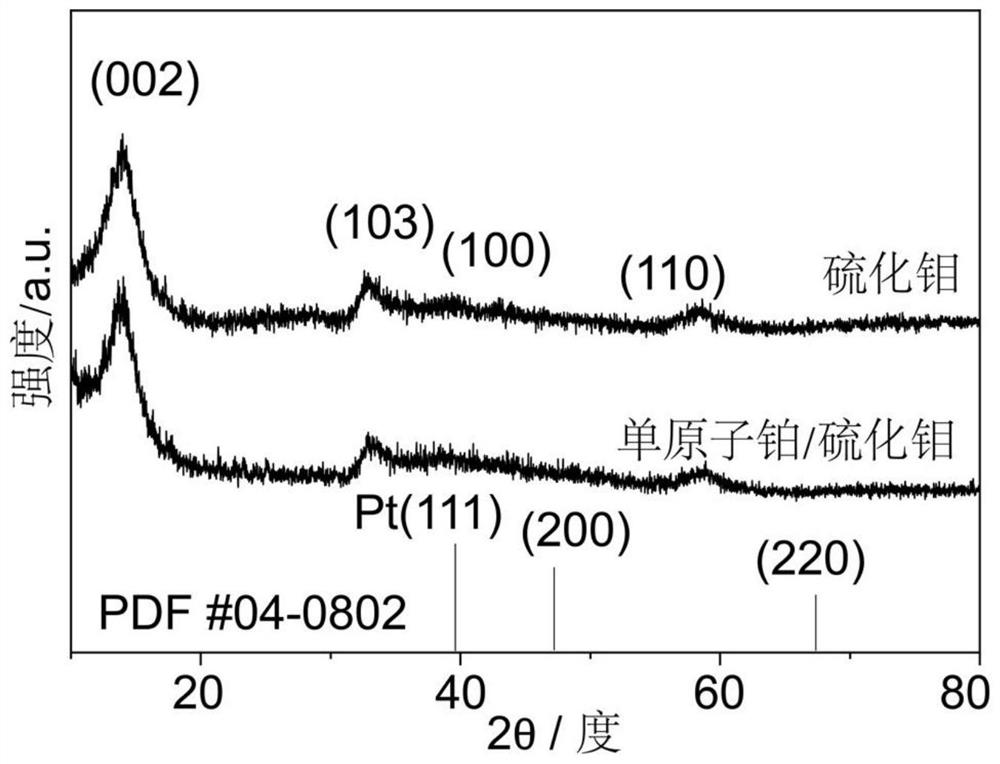

[0034] (1) The blocky molybdenum sulfide is stripped by chemical stripping method of lithium ion intercalation, and the molybdenum sulfide suspension is synthesized by mixing 0.6g blocky molybdenum sulfide and 8mL 1.6mol L -1 The butyllithium / hexane solution was mixed, and the mixture was reacted in an oil bath at 60° C. for 48 hours. The obtained product was filtered and washed with 80 mL of hexane. After filtration, the product is dissolved in water and subjected to ultrasonic stripping to obtain a molybdenum sulfide dispersion.

[0035] (2) Make the concentration 0.125mg mL -1 The molybdenum sulfide suspension is modified on the surface of the glassy carbon electrode, in argon-saturated 2 mmol / L copper sulfate 0.1 mol / L sulfuric acid precursor solution, at a potential of 0.1 volts (reference silver / silver chloride electrode) Underpotential deposition was performed for 200 seconds.

[0036] (3) The electrode after underpotential deposition is quickly transferred to argon-...

Embodiment 2

[0041] The preparation method of this example is the same as that of Example 1, and the underpotential deposition time of step 2 is adjusted to 30 seconds. Under the condition that other conditions remain unchanged, a single-atom platinum-molybdenum sulfide nanocomposite is obtained.

Embodiment 3

[0043] The preparation method of this example is the same as that of Example 1, the underpotential deposition time of step 2 is adjusted to 60 seconds, and under the condition that other conditions remain unchanged, a single-atom platinum-molybdenum sulfide nanocomposite is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com