Chondroitin sulfate modified collagen/polycaprolactone vascular repair scaffold and preparation method and application thereof

A chondroitin sulfate and collagen technology, applied in the field of biomedical materials, can solve the problems of chondroitin sulfate chemical structure and biological activity changes, unfavorable dissolution, low mechanical strength and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

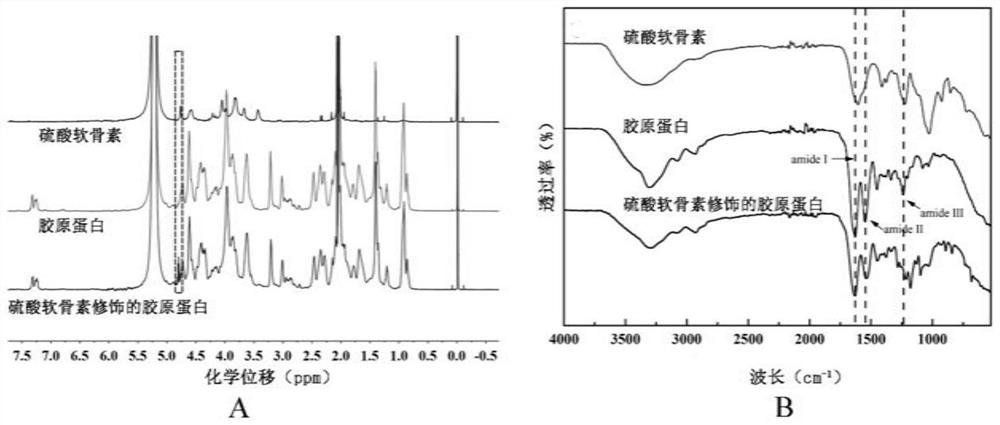

[0054] Example 1: Preparation of Collagen Modified by Chondroitin Sulfate

[0055] Weigh 120mg of collagen, shred it and place in 5mL hexafluoroisopropanol / 0.1M NaHCO with a volume ratio of 3:2 3 In the oil / water emulsion system (pH 7.0) composed of the solution, chondroitin sulfate was added to the above system in different mass ratios (collagen: chondroitin sulfate=6:1, 5:1, 4:1, 3:1) After recrystallization, sodium cyanoborohydride was added to the above system in an amount 1.5 times the mass of chondroitin sulfate, and the reaction solution was obtained by magnetic stirring at room temperature at 300 rpm for 24 hours; after the reaction was completed, 4 times the reaction solution was added to the reaction bottle. 5% (volume fraction) of acetic acid solution by volume; select an ultrafiltration tube with a molecular weight cut-off of 30kDa, and perform ultrafiltration and centrifugation at a speed of 3500~4200r / min for 20~30min; resuspend with 5% (volume fraction) of aceti...

Embodiment 2

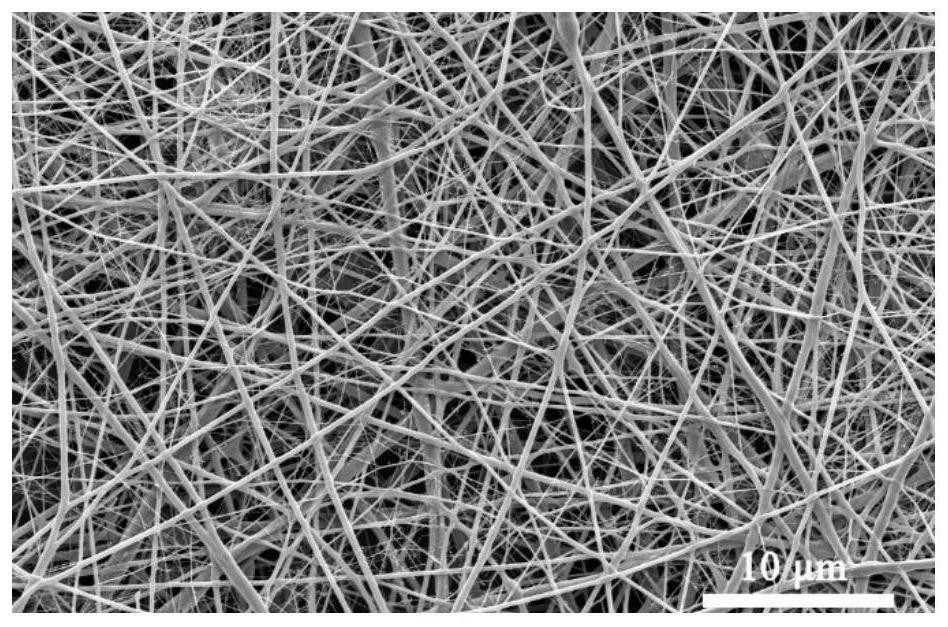

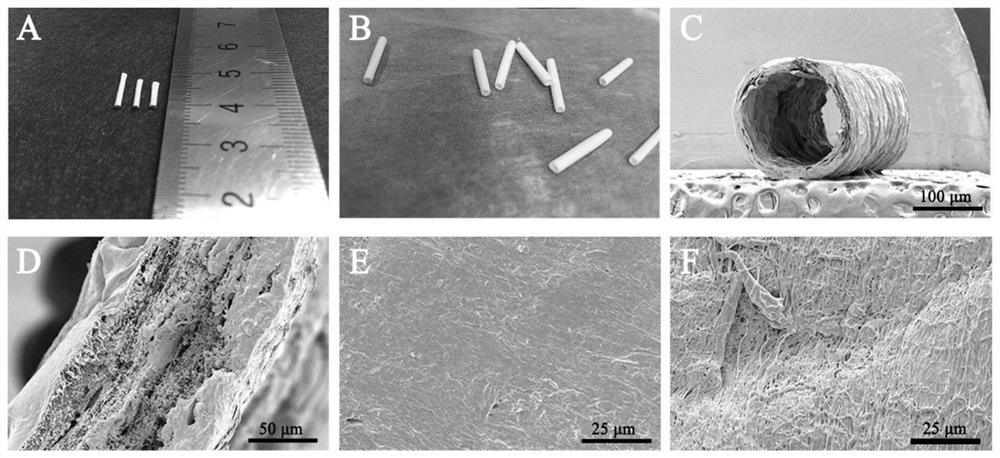

[0057] Example 2: Preparation and crosslinking of collagen / polycaprolactone nanofibers modified by chondroitin sulfate

[0058] (1) Preparation of collagen / polycaprolactone nanofibers modified by chondroitin sulfate

[0059] The chondroitin sulfate-modified collagen and polycaprolactone prepared in Example 1 were added to hexafluoroisopropanol, the mass ratio of the chondroitin sulfate-modified collagen to polycaprolactone was 5:3, and the total mass of the two The percentage concentration is 8% (g / mL), magnetically stirred at room temperature until the wall-hanging spinning solution is visible to the naked eye, and then electrospun; during spinning, the spinning equipment is placed in a fume hood at room temperature, and the temperature is 20-30°C , the ambient humidity is less than 30%, use a syringe to draw 1mL of spinning solution and fix it in the micro-syringe pump, and connect the metal needle of the syringe to the high-voltage generator through the power cord; the inne...

Embodiment 3

[0064] Example 3: Determination of mechanical properties of stents for vascular repair.

[0065] In order to detect the mechanical properties of the blood vessel repair stent made in Example 2, use the GTM 8050S microcomputer servo control electronic universal material testing machine to connect with the computer control end, fix the two ends of the test sample on the mechanical tester fixture in a wet state, adjust Grip spacing, taking care to ensure that the sample is not stretched, measures its effective length. The mechanical test mode is under the tubular mode, stretching at a constant speed of 10mm / min until the sample breaks, and recording the stress-strain curve ( Figure 4 A), modulus of elasticity ( Figure 4 B), elongation ( Figure 4 C) and ultimate tensile strength ( Figure 4 D). Depend on Figure 4It can be seen that polycaprolactone has made up for the deficiency in the mechanical properties of natural materials as a mechanical reinforcement material, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com