Low-temperature semiconductor direct bonding method based on surface modification and activation

A direct bonding and surface modification technology, which is applied in the field of solar cells, can solve the problems of commercialization of multi-junction solar cells, and achieve the effects of batch preparation, improved photoelectric conversion efficiency, and good interface crystallization quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

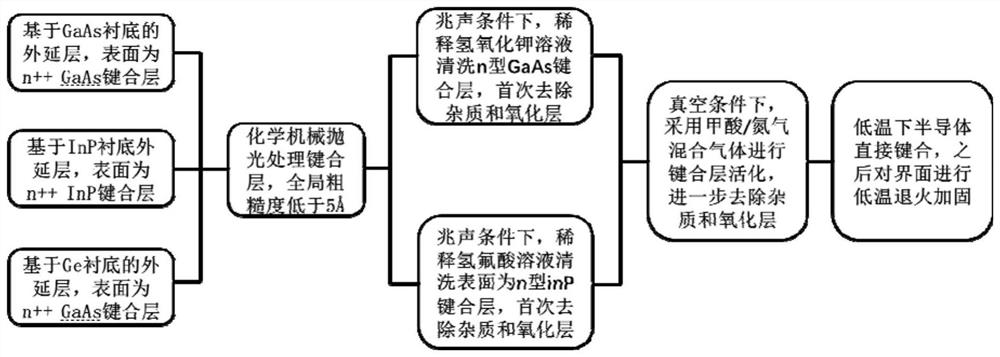

Method used

Image

Examples

Embodiment 1

[0027] This embodiment discloses a method for preparing a 5-junction solar cell based on direct bonding of surface modification and activated low-temperature semiconductor, including the following steps:

[0028] 1. Sub-battery epitaxial growth and structure:

[0029] (1) The thickness is 350 μm, the crystal orientation is (100), and the doping concentration is about 10 17 cm -3 ~10 18 cm -3 The n-type GaAs wafer is used as the substrate, and the three-junction sub-cell structure is epitaxially grown on the GaAs substrate by metal-organic vapor phase epitaxy (MOVPE), which in turn includes (Al x Ga 1-x ) y In 1-y P subcell structure, fourth tunnel junction structure, Al with a bandgap of 1.7eV x Ga 1-x As sub-cell structure, the third tunnel junction structure, GaAs sub-cell structure with a band gap of 1.4eV and the second tunnel junction structure; the specific content (x, y values) of Al, Ga, In and other components can be determined by the material The band gap is...

Embodiment 2

[0041] This embodiment discloses a method for preparing a 4-junction solar cell based on direct bonding of surface modification and activated low-temperature semiconductor, including the following steps:

[0042] 1. Sub-battery epitaxial growth and structure:

[0043] (1) The thickness is 350 μm, the crystal orientation is (100), and the doping concentration is about 10 17 -10 18 cm -3 The n-type GaAs wafer is used as the substrate, and the metal-organic vapor phase epitaxy (MOVPE) is used to epitaxy the two-junction sub-cell structure on the substrate, followed by GaxIn with a bandgap width of 1.8eV 1-x The P subcell structure, the third tunnel junction structure, the GaAs subcell structure with a bandgap of 1.4eV, and the second tunnel junction structure; the specific content (x value) of Ga, In and other components can be determined by the material band The gap is calculated; the tunnel junction is mainly composed of a thickness of only a dozen nanometers and a doping co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com