Preparation method of heterogeneous solid catalyst for preparing ammonia by hydrolyzing urea

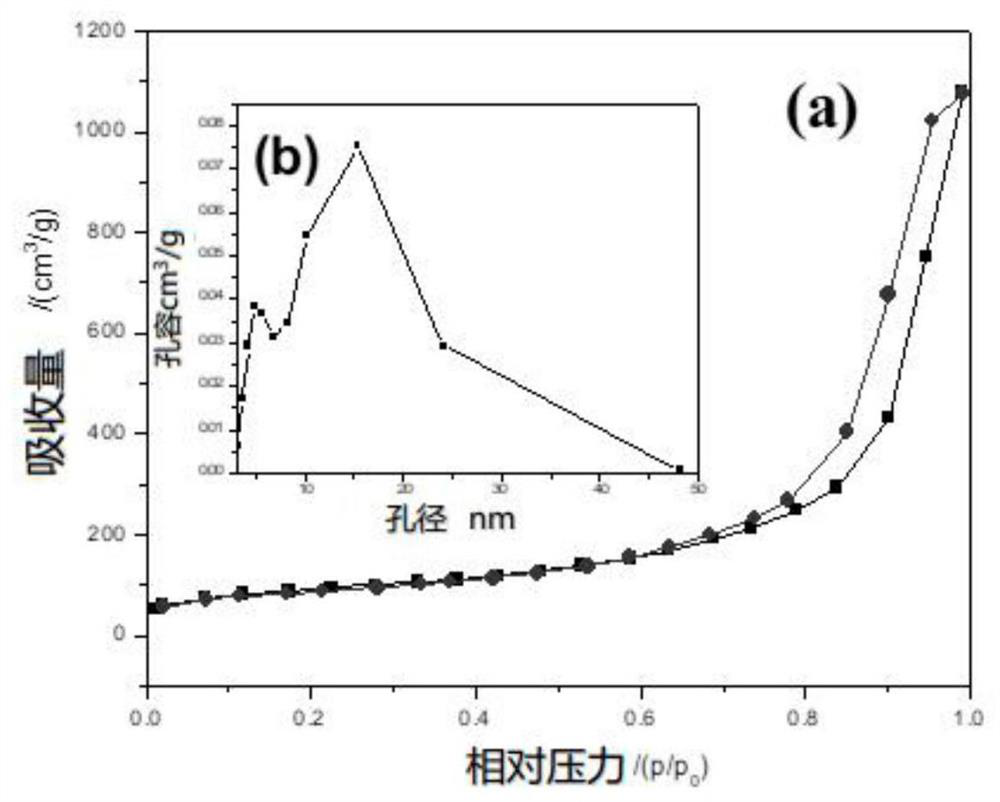

A solid catalyst, a technology for urea hydrolysis, which is applied in the preparation/separation of ammonia, chemical instruments and methods, catalysts for physical/chemical processes, etc., can solve the problems of high preparation cost and active site exposure, and achieves low preparation cost and simple preparation. , the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

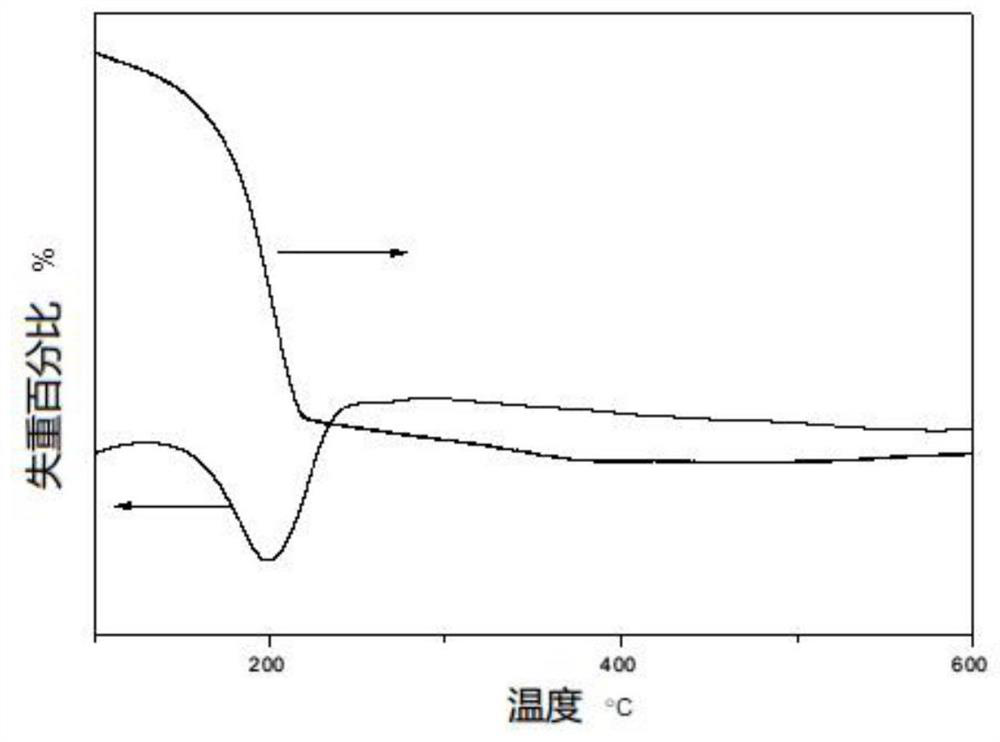

[0032] Embodiment 1 of the present invention: a preparation method of a heterogeneous solid catalyst for ammonia production by hydrolysis of urea:

[0033] Preparation of S1 alumina precursor: Fully grind aluminum nitrate powder and ammonium bicarbonate powder at room temperature, the molar ratio of aluminum nitrate: ammonium bicarbonate is 1:4; then mix the two powders and continue grinding until it becomes a milky white paste The milky white paste substance was placed in a crystallization kettle for aging at 80°C for 7 hours, then washed with deionized water, filtered with suction, and dried at 120°C for 6 hours to obtain aluminum ammonium carbonate powder, an alumina precursor;

[0034]Preparation of S2 catalyst carrier: Mix the aluminum ammonium carbonate powder obtained in step S1, the lubricant (squat powder) and the pore structure modifier (nano carbon black), and slowly add the binder (by mass ratio of 1: 20 The acid peptizer prepared from nitric acid and water), fully...

Embodiment 2

[0040] Embodiment 2: A kind of preparation method of the heterogeneous solid catalyst that is used for urea hydrolysis to produce ammonia:

[0041] Preparation of S1 alumina precursor: Fully grind aluminum nitrate powder and ammonium bicarbonate powder at room temperature, add structural aid (PEG-400) to the ammonium bicarbonate powder and mix evenly, aluminum nitrate: ammonium bicarbonate: PEG- The molar ratio of 400 is 1:4:0.036; then mix the two powders, and continue to grind until it becomes a milky white paste; place the milky white paste in a crystallization kettle for aging at 80°C for 7 hours, and then wash it with deionized water , suction filtration, and drying at 120°C for 6 hours to obtain aluminum oxide precursor ammonium aluminum carbonate powder;

[0042] Preparation of S2 catalyst carrier: Mix the aluminum ammonium carbonate powder obtained in step S1, the lubricant (Tanjing powder) and the pore structure modifier (nano carbon black), and slowly add the binder ...

Embodiment 3

[0048] Embodiment 3: A kind of preparation method of the heterogeneous solid catalyst that is used for urea hydrolysis to produce ammonia:

[0049] Preparation of S1 alumina precursor: Fully grind aluminum nitrate powder and ammonium bicarbonate powder at room temperature, add structural aid (PEG-200) to the ammonium bicarbonate powder and mix evenly, aluminum nitrate: ammonium bicarbonate: PEG- The molar ratio of 200 is 1:4:0.036; then mix the two powders, and continue to grind until it becomes a milky white paste; put the milky white paste in a crystallization kettle for aging at 80°C for 7 hours, and then wash it with deionized water , suction filtration, and drying at 100°C for 2 hours to obtain aluminum oxide precursor ammonium aluminum carbonate powder;

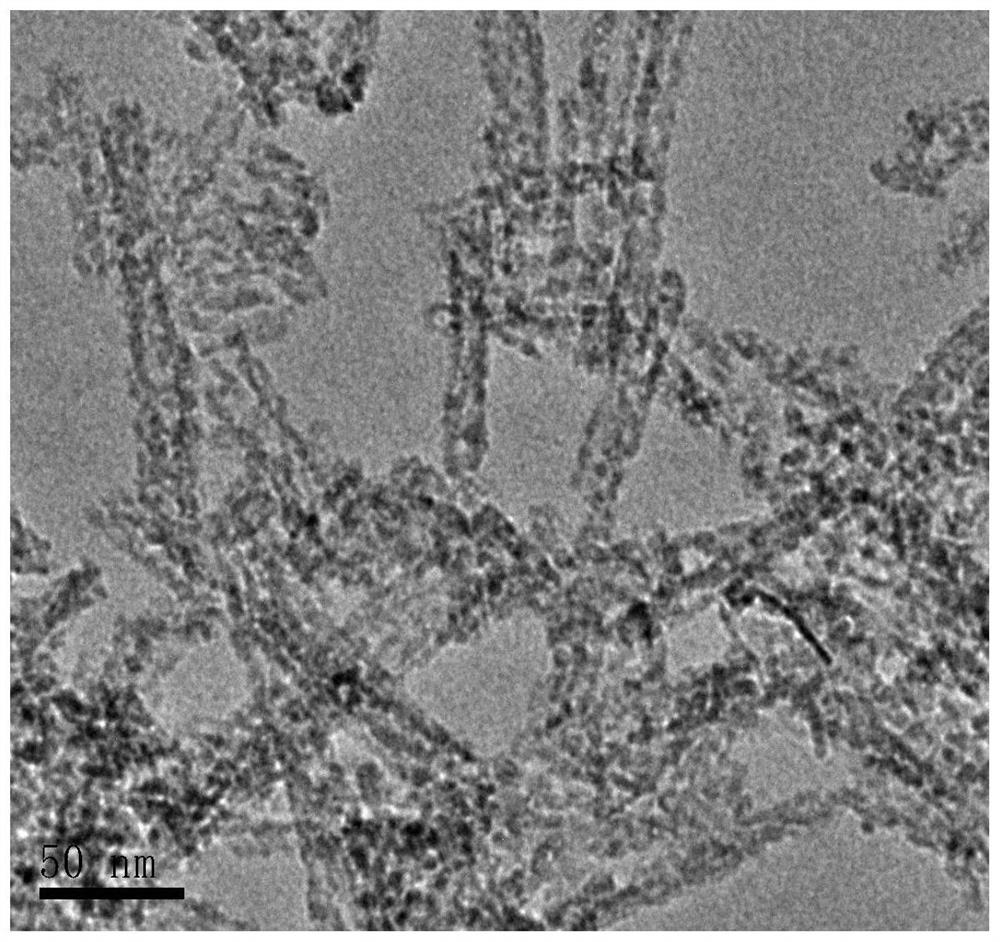

[0050] Preparation of S2 catalyst carrier: Mix the ammonium aluminum carbonate powder, lubricant (talcum powder) and pore structure modifier (carbon nanofiber) obtained in step S1, and slowly add the binder (by mass rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com