Quick-curing powder coating and preparation method thereof

A powder coating, fast curing technology, applied in the direction of powder coating, polyester coating, coating, etc., can solve the problems of difficulty in taking into account the coating forming process, difficulty in adapting to performance requirements, and low environmental tolerance, so as to reduce the curing time, Strengthen the bonding effect and improve the strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

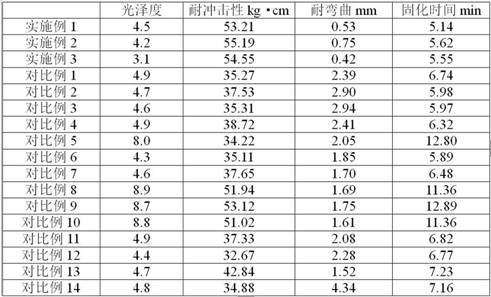

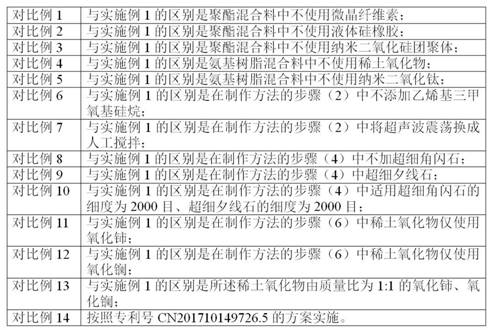

Embodiment 1

[0032]A fast-curing powder coating, in parts by mass, the polyester mixture formula is: 30 parts of polyarylate, 40 parts of polybutylene terephthalate, 1 part of polyethylene micropowder wax, 0.5 parts of microcrystalline cellulose parts, 3 parts of polyvinyl acetate, 1 part of liquid silicone rubber, 55 parts of nano-silica aggregates, 30 parts of barium sulfate, and 5 parts of melamine formaldehyde resin; the formula of the amino resin mixture is: 50 parts of urea-formaldehyde resin, 10 parts of rubber, 0.1 part of rare earth oxide, 20 parts of dull calcium carbonate, 5 parts of polyacrylonitrile, 1 part of nano-titanium dioxide, 0.5 part of polyvinylidene fluoride resin; the mass ratio of the polyester compound and the amino resin compound 1:2; the nano-silica aggregate is made of the following components by mass: 1 part of nano-silica, 0.5 parts of vinyltrimethoxysilane, 20 parts of benzene, 18 parts of acrylic resin, superfine 1 part of hornblende, 0.5 part of superfine ...

Embodiment 2

[0049] A fast-curing powder coating, in parts by mass, the polyester mixture formula is: 50 parts of polyarylate, 70 parts of polybutylene terephthalate, 3 parts of polyethylene micropowder wax, 1 part of microcrystalline cellulose parts, 5 parts of polyvinyl acetate, 3 parts of liquid silicone rubber, 65 parts of nano-silica aggregates, 40 parts of barium sulfate, and 8 parts of melamine formaldehyde resin; the formula of the amino resin mixture is: 80 parts of urea-formaldehyde resin, 20 parts of rubber, 0.3 part of rare earth oxide, 30 parts of dull calcium carbonate, 8 parts of polyacrylonitrile, 3 parts of nano-titanium dioxide, 2 parts of polyvinylidene fluoride resin; the mass ratio of the polyester compound and the amino resin compound 3:5; the nano-silica aggregate is made of the following components by mass: 2 parts of nano-silica, 0.7 parts of vinyltrimethoxysilane, 25 parts of benzene, 22 parts of acrylic resin, superfine 1.5 parts of hornblende, 0.8 part of superf...

Embodiment 3

[0066] A fast-curing powder coating, in parts by mass, the polyester mixture formula is: 40 parts of polyarylate, 57 parts of polybutylene terephthalate, 2 parts of polyethylene micropowder wax, 0.9 parts of microcrystalline cellulose parts, 4 parts of polyvinyl acetate, 3 parts of liquid silicone rubber, 55 parts of nano-silica aggregates, 40 parts of barium sulfate, and 5 parts of melamine formaldehyde resin; the formula of the amino resin mixture is: 80 parts of urea-formaldehyde resin, 20 parts of rubber, 0.1 part of rare earth oxide, 30 parts of dull calcium carbonate, 5 parts of polyacrylonitrile, 3 parts of nano-titanium dioxide, 0.5 part of polyvinylidene fluoride resin; the mass ratio of the polyester compound and the amino resin compound 3:2; the nano-silica aggregate is made of the following components by mass: 2 parts of nano-silica, 0.5 parts of vinyltrimethoxysilane, 25 parts of benzene, 22 parts of acrylic resin, superfine 1 part of hornblende, 0.8 part of super...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com