Batch production method of doped modified calcium-based CO2 adsorbent spheres

A calcium-based adsorbent, mass production technology, applied in the direction of separation methods, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve problems related to the batch preparation of adsorbents, and achieve high industrial Application prospect, ease of extrusion, effect of slowing down the sintering phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

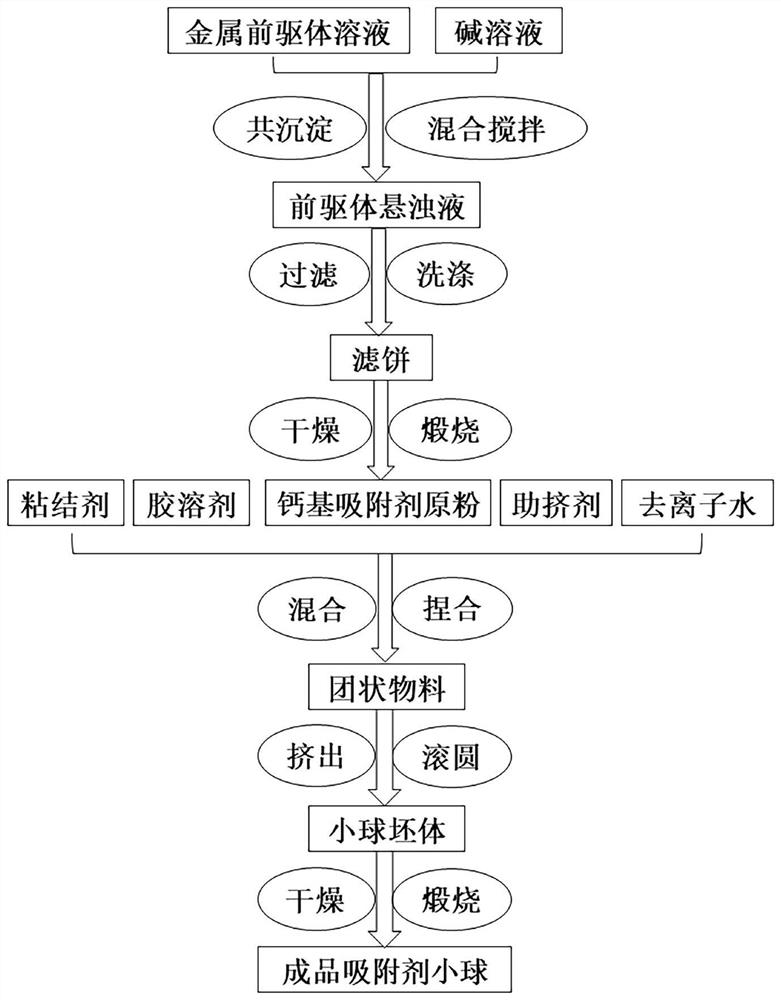

Method used

Image

Examples

Embodiment 1

[0054] 1) Dissolve 3kg of calcium nitrate and 670g of aluminum nitrate (the molar ratio of calcium to aluminum is about 7:1) in 8L of deionized water, and mix to obtain a metal precursor solution; then dissolve 1.2kg of sodium hydroxide in 12L of deionized water After mixing, an alkali solution is obtained; the metal precursor solution and the alkali solution are mixed and stirred by a coprecipitation method, and then configured into a suspension;

[0055] 2) Stir the suspension continuously at a stirring speed of 300rpm, a co-precipitation temperature of 25°C, and a co-precipitation time of 24h; use a plate and frame filter press to wash and filter the stirred suspension to obtain a filter cake. The mass ratio of deionized water to suspension is 10:1; put the filter cake in a resistance furnace and dry at 100°C for 12 hours to obtain a dry filter cake, then crush the dry filter cake and put it in a resistance furnace at 600°C Roast for 2 hours to obtain the original powder of...

Embodiment 2

[0059] 1) The amounts of metal precursors, alkaline reagents and deionized water in this example are consistent with those in Example 1);

[0060] 2) Stir the suspension continuously at a stirring speed of 100rpm, a co-precipitation temperature of 10°C, and a co-precipitation time of 12h; use a plate and frame filter press to wash and filter the stirred suspension to obtain a filter cake. The mass ratio of deionized water to suspension is 10:1; put the filter cake in a resistance furnace and dry at 110°C for 10 hours to obtain a dry filter cake, then crush the dry filter cake and put it in a resistance furnace at 700°C Roasting for 1h, the original powder of doped modified calcium-based adsorbent is obtained;

[0061] 3) The molding process of the former powder of the calcium-based adsorbent made in the present embodiment is consistent with the steps described in Example 1);

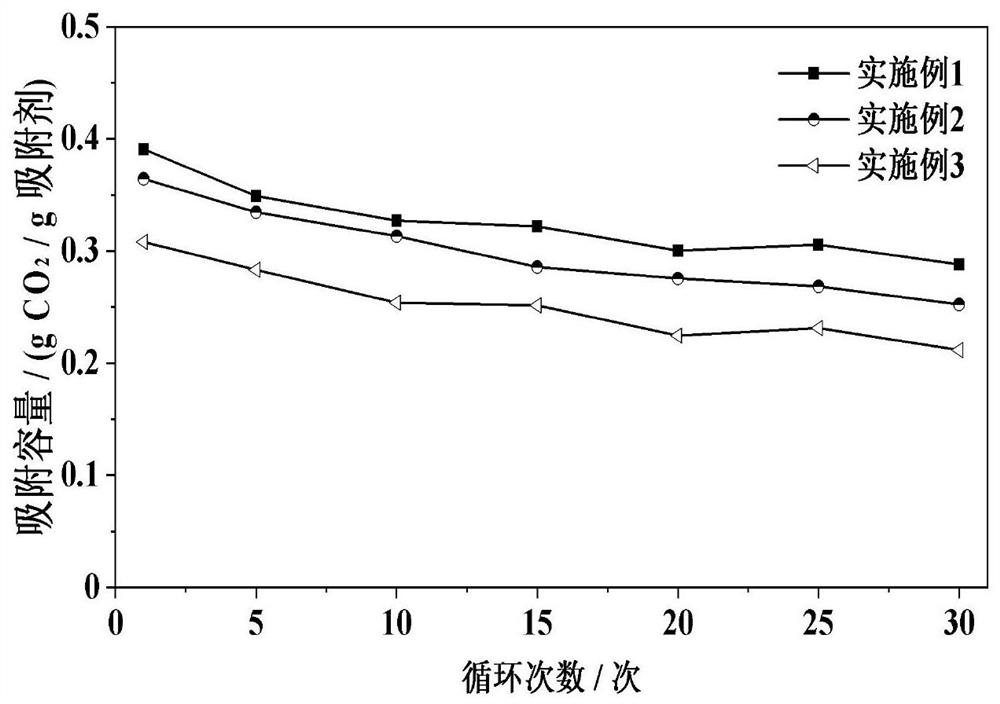

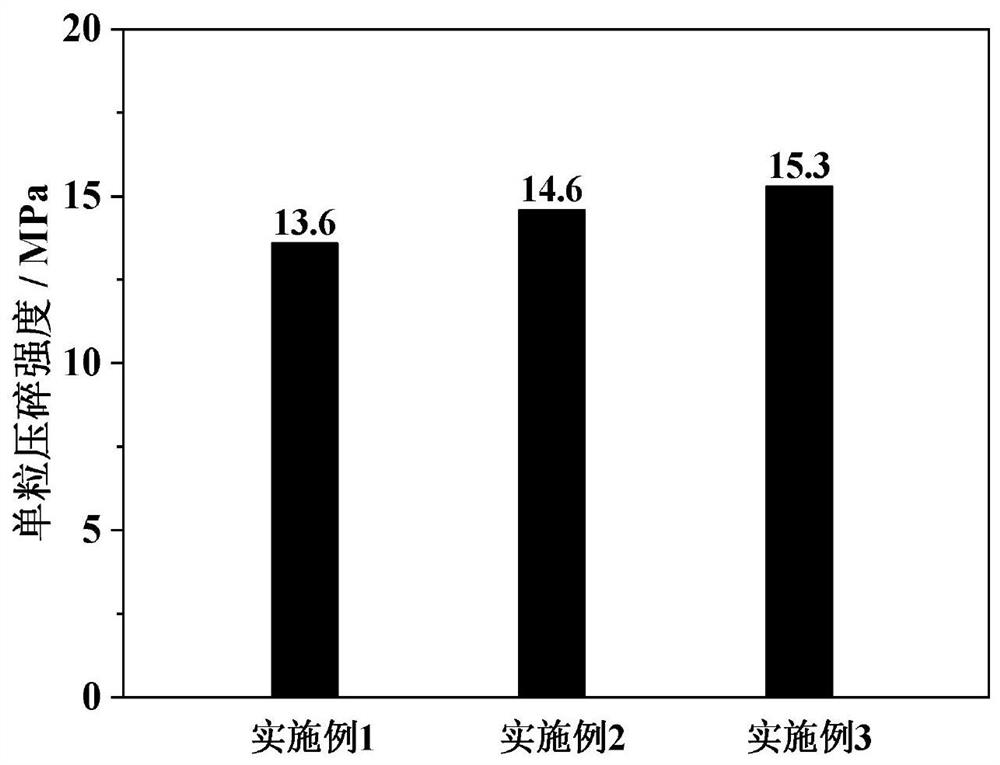

[0062] The calcium-based adsorbent pellets synthesized in this example were subjected to CO 2 Adsor...

Embodiment 3

[0065] 1) Dissolve 20kg of calcium nitrate and 3.2kg of aluminum nitrate (the molar ratio of calcium to aluminum is about 10:1) in 25L of deionized water respectively, and mix to obtain a metal precursor solution; then dissolve 5kg of sodium hydroxide in 60L of deionized water After mixing, an alkali solution is obtained; the metal precursor solution and the alkali solution are mixed and stirred by a coprecipitation method, and then configured into a suspension;

[0066] 2) Stir the suspension continuously at a stirring speed of 200 rpm, a co-precipitation temperature of 20°C, and a co-precipitation time of 18 hours; use a plate and frame filter press to wash and filter the stirred suspension to obtain a filter cake. The mass ratio of deionized water to suspension is 15:1; put the filter cake into the resistance furnace and dry at 120°C for 6 hours to obtain a dry filter cake, then crush the dry filter cake and put it in the resistance furnace at 700°C Roast for 2 hours to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com