Amino magnetic nanoparticle coating method and application thereof

A magnetic nanometer and magnetic particle technology, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve the problems of not meeting the requirements of potency and low potency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

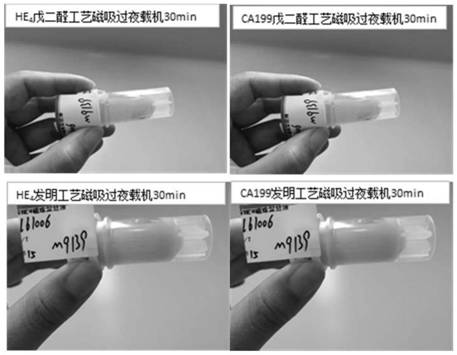

[0024] Example 1: Coated magnetic particle HE 4 (human epididymis protein 4) process:

[0025] Take Merck amino magnetic nanoparticles (100mg / ml, 40μl), wash 5 times (0.1MPBS 400μl×5 times) to remove the supernatant, add 50μl (1mg / ml, dissolved in MES buffer) polyacrylic acid solution and 50μl (20mg / ml, the EDC solution of MES (that is, 2-(N-morpholine) ethanesulfonic acid) buffer solution), the rapid mixer shakes evenly, and places on the shaker for 2h;

[0026] Use a magnet to remove the supernatant, add coating solution 85μl MES buffer and 15ulHE 4 Coat live materials, vibrate evenly with a fast mixer and place on an oscillator to vibrate for 2 hours;

[0027] Use HE 4 The sealing solution was washed 5 times (400 μl × 5 times), and the sealing solution was fixed to 3 mL; the sealing solution included 1000 mL of 0.1M phosphate buffer (pH=7.4) with 10 g of BSA and 1 mL of Tween 20 (surfactant ) and 1 mL of sodium azide (preservative).

Embodiment 2

[0028] Embodiment 2: the process of coating magnetic particle CA199:

[0029] Take Merck amino magnetic nanoparticles (100mg / ml, 40μl), wash 5 times (0.1M PBS 400μl×5 times) to remove the supernatant, add 50ul (1mg / ml, dissolved in PBS) polyacrylic acid solution and 50μl (10mg / ml ml, dissolved in 0.1M PBS) of EDC solution, oscillate evenly with a rapid mixer, and then place it on the shaker for 2h;

[0030] Remove the supernatant after magnetic suction with a magnet, add coating solution 85 μl 0.1M PBS buffer and 15 μl CA199 (carbohydrate antigen 199) to coat the living material, shake it evenly with a fast mixer, and place it on the shaker for 2 hours;

[0031] Use CA199 sealing solution to wash 5 times (400μl×5 times), and seal to 3mL; the sealing solution includes 1000mL of 0.1M phosphate buffer (pH=7.4) with 10gBSA and 1mL of Tween 20 (surfactant agent) and 1 mL of sodium azide (preservative).

[0032] The present invention adopts Antu Biological A2000Plus detection inst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com