Process for producing reclaimed water

A manufacturing method, technology of reclaimed water, applied in water treatment parameter control, chemical instruments and methods, water/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] (Example of the invention of claim 1)

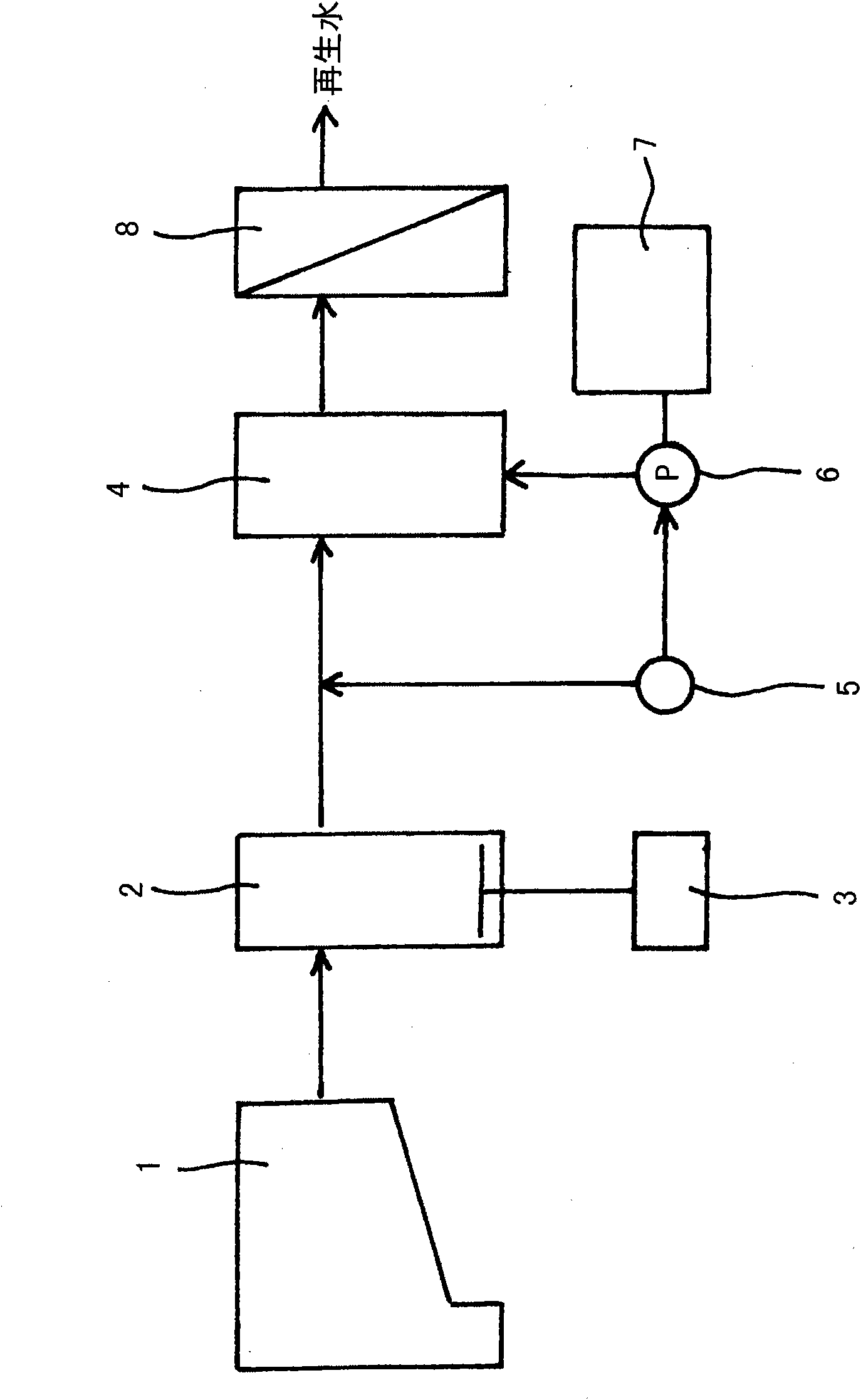

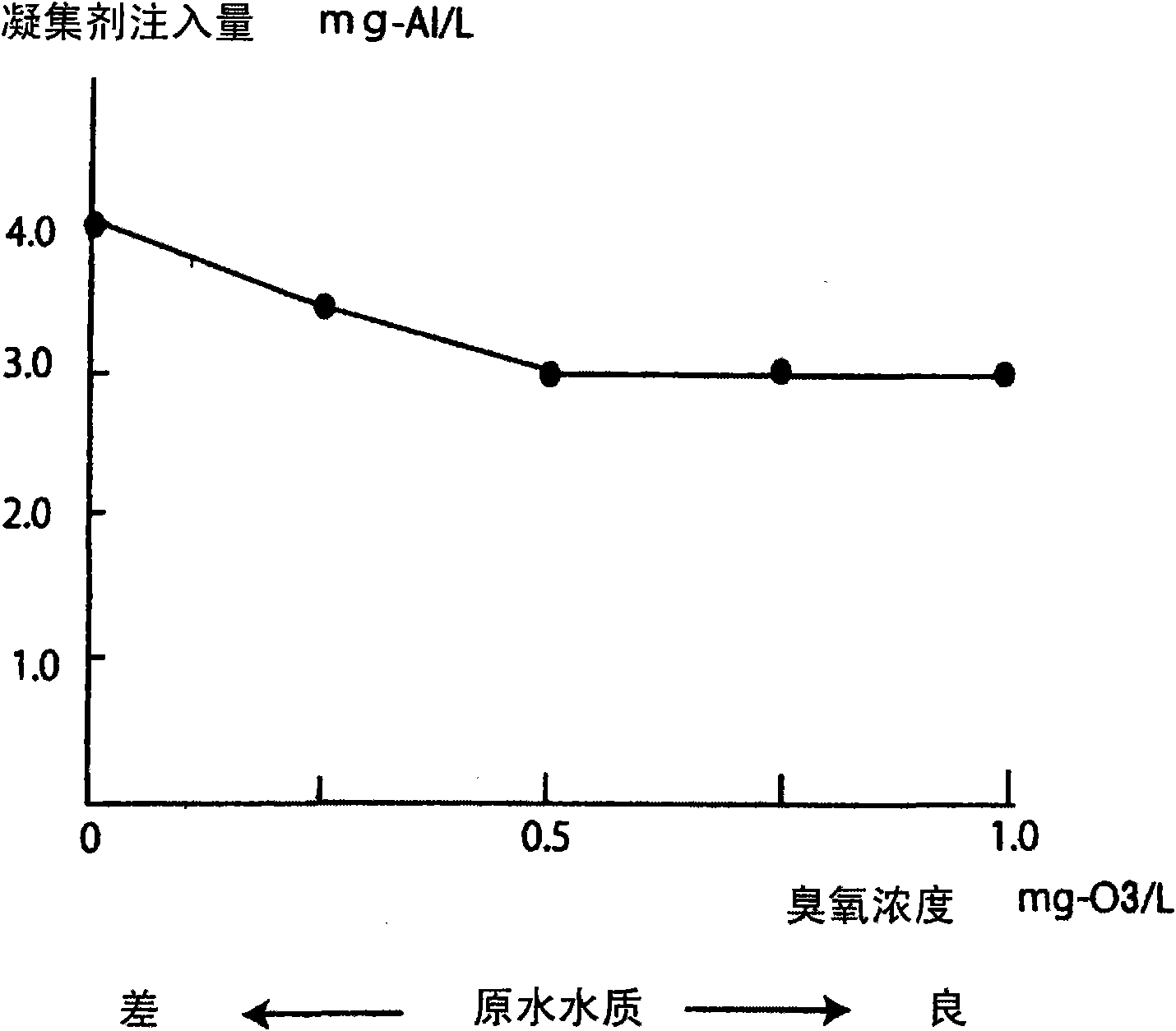

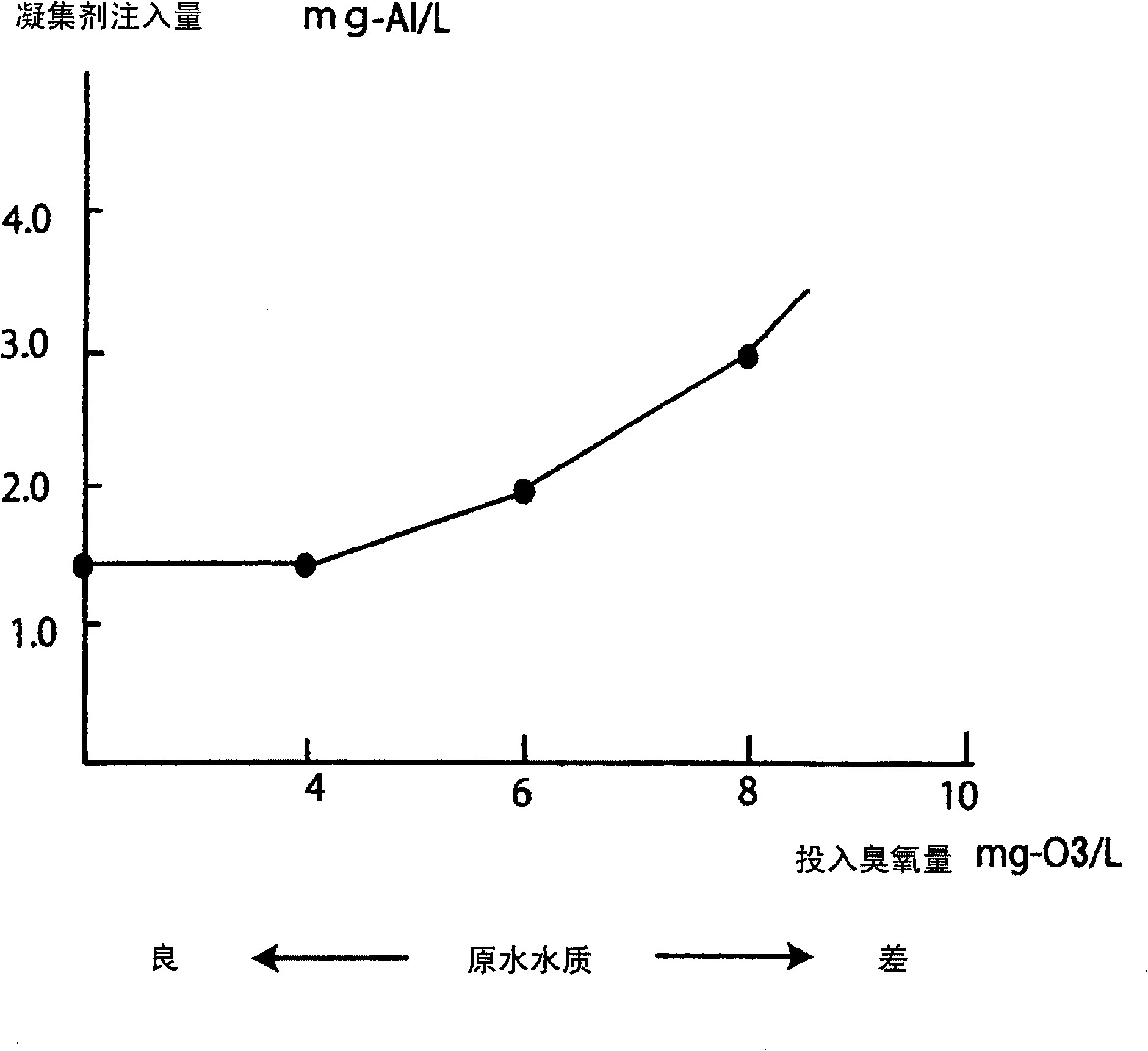

[0043] Use the sewage treatment wastewater discharged from the sewage treatment plant as raw water, use figure 1 The device shown produces reclaimed water. The ozone injection amount was set at 6 to 10 mg / L so that the residual ozone concentration in the raw water before coagulation was in the range of 0.3 to 1.0 mg / L. The coagulant uses PAC, and the residual ozone concentration in the raw water before coagulation decreases by 0.1mg / L from 0.5mg / L, and the injection amount of PAC increases by 0.2mg-Al / L, otherwise, when it is above 0.5mg / L , so that the injection amount of PAC is fixed at 3.0mg-Al / L. The water quality of raw water and recycled water at this time is shown in Table 1. In addition, the water quality of regenerated water when the injection amount of PAC was not changed even if the concentration of residual ozone in raw water before coagulation was changed is shown in Table 2 as a comparative example.

[0044] [Tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com