A kind of high out-of-plane thermal conductivity polyimide film and preparation method thereof

A polyimide film and thermal conductivity technology, applied in the field of polyimide materials, can solve the problem of difficult to achieve the patent orientation effect, achieve good electrical properties and mechanical properties, improve thermal conductivity, and improve the effect of interface bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

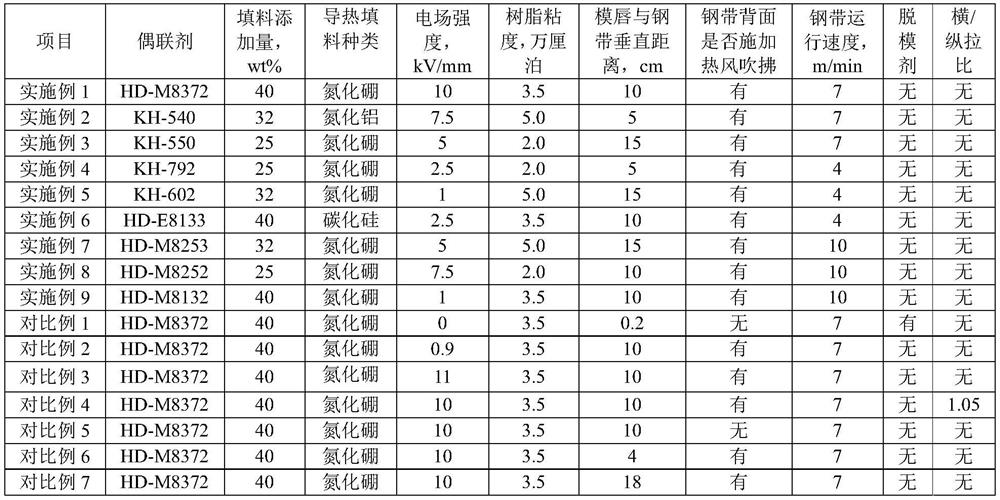

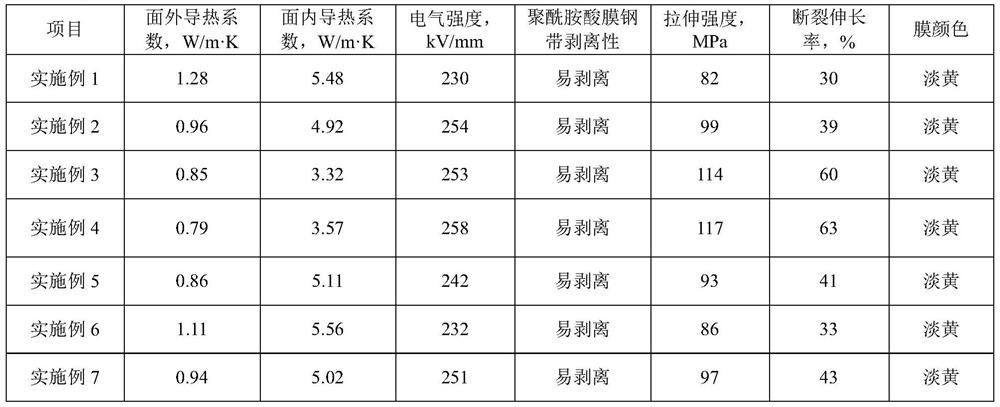

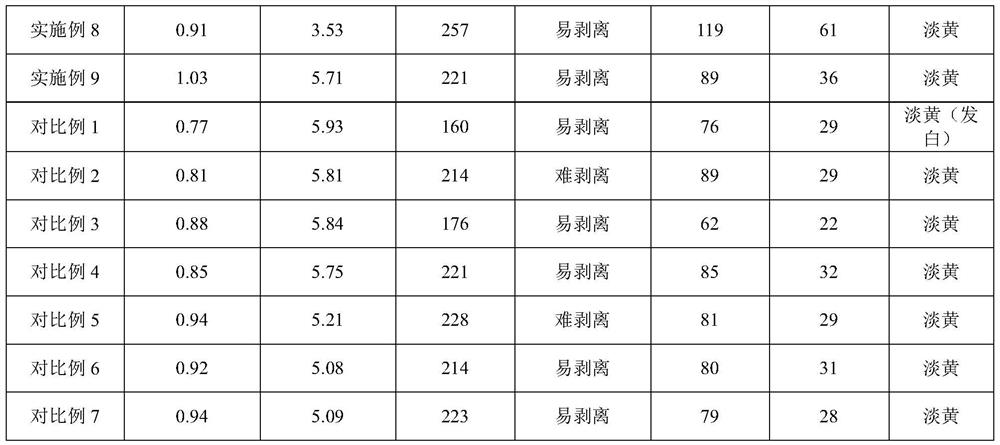

Embodiment 1

[0032] 1) Mix 43.33kg of thermally conductive filler (boron nitride (particle size: 0.1-20μm), 390kg of N,N-dimethylacetamide and 0.65kg of amino functional group-containing silane coupling agent (HD-M8372), and ultrasonicate for 2 hours. Get the mixed solution, set aside;

[0033] 2) At room temperature, add 31.11kg of 4,4',-diaminodiphenyl ether (ODA) and 45kg of dimethylacetamide (DMAC) into the reactor according to the conventional process, stir and dissolve and add the mixture obtained in step 1) After stirring evenly, it is mixed with pyromellitic dianhydride (PMDA) with a diamine molar ratio of 1:1 (adding in batches) to synthesize a polyamic acid resin with a viscosity of 35,000 centipoise (thermally conductive filler doped Amount is 40wt%), defoaming, obtains defoaming polyamic acid resin;

[0034] 3) adjust the die head of the film casting extrusion equipment, so that the vertical distance between the lip of the die lip on the die head and the steel strip is 10cm; ...

Embodiment 2

[0039] Repeat Example 1, the difference from Example 1 is:

[0040] The amino functional group-containing silane coupling agent is KH-540, the thermally conductive filler is aluminum nitride, the doping amount is 32wt%, the AC electric field strength is 7.5kV / mm, and the polyamic acid resin obtained by synthesis has a viscosity of 50,000 centipoise. The vertical distance between the lip of the lip and the steel strip is 5cm.

Embodiment 3

[0042] Repeat Example 1, the difference from Example 1 is:

[0043] The amino functional group-containing silane coupling agent is KH-550, the doping amount of thermally conductive filler is 25wt%, the AC electric field strength is 5kV / mm, and the viscosity of the synthesized polyamic acid resin is 20,000 centipoise. The vertical distance of the strips is 15 cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com