Preparation method of composite catalyst applied to photo-thermal-coupled methanol steam reforming for hydrogen production

A composite catalyst, photothermal coupling technology, applied in catalyst activation/preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc. Hydrogen, high-performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

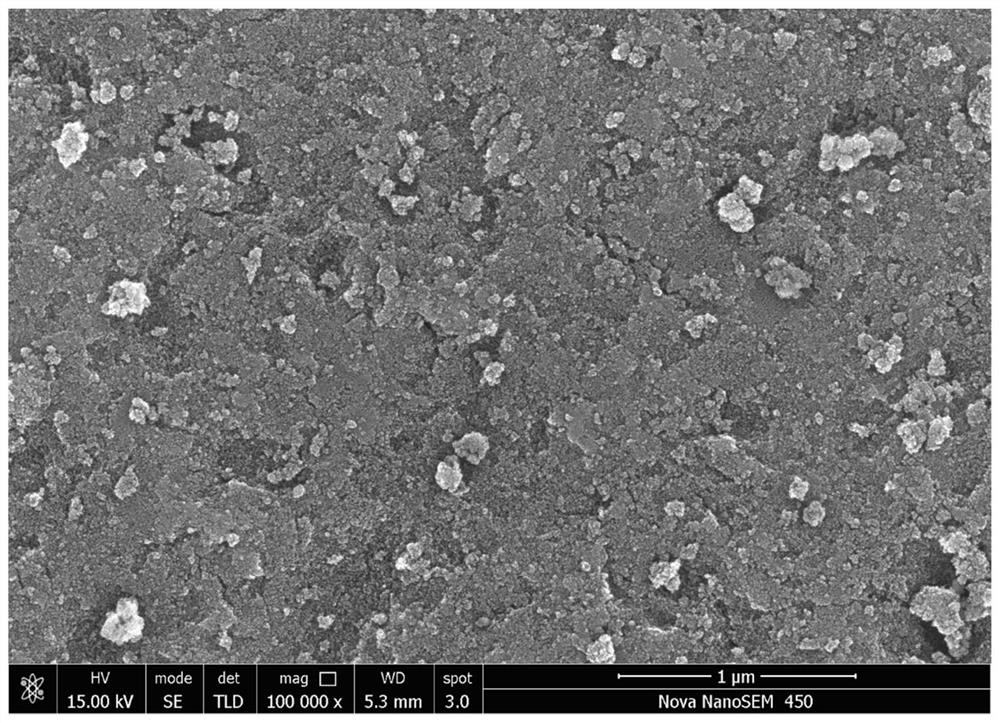

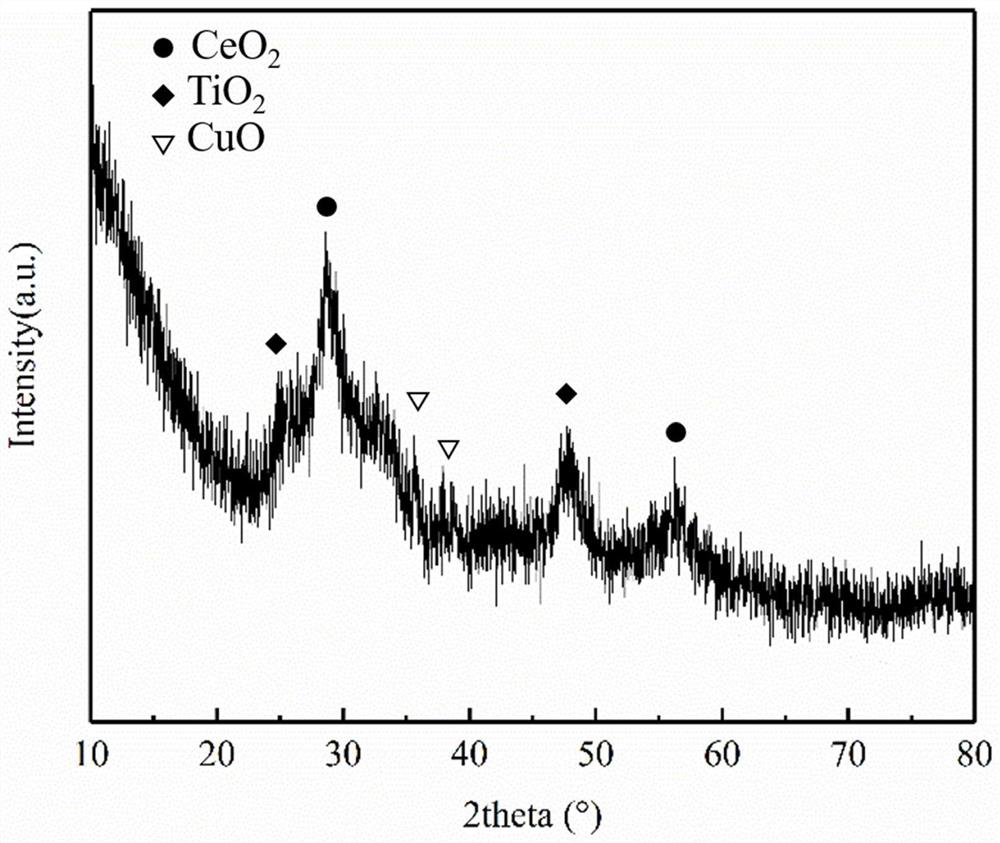

[0037] Example 1: Cu / TiO 2 -CeO 2 preparation of

[0038] Preparation of binary porous carrier TiO by sol-gel method 2 -CeO 2 .

[0039] (1) Dissolve 3.2 g of surfactant polyether F127 in 60 ml of ethanol, and stir magnetically at 40° C. for 30 minutes to form solution 1;

[0040] (2) 7ml of tetrabutyl titanate, 4.6ml of glacial acetic acid, 1.6ml of nitric acid and cerium nitrate hexahydrate (0.01-0.04mol) corresponding to different molar ratios (Ti / Ce) were added to the first solution in sequence and added at 40 Stir magnetically at ℃ for 2 hours, during which a wet gel is formed;

[0041] (3) Place the wet gel in a petri dish, and age it for 12 hours at a temperature of 40° C. and a humidity of 40%, during which a dry gel is formed;

[0042] (4) Dry the aged sample at 100°C for 12 hours;

[0043] (5) The dried product was calcined at 450°C at a heating rate of 1°C / min for 5h, and cooled to room temperature at 2°C / min, and ground to obtain the final binary porous carr...

Embodiment 2

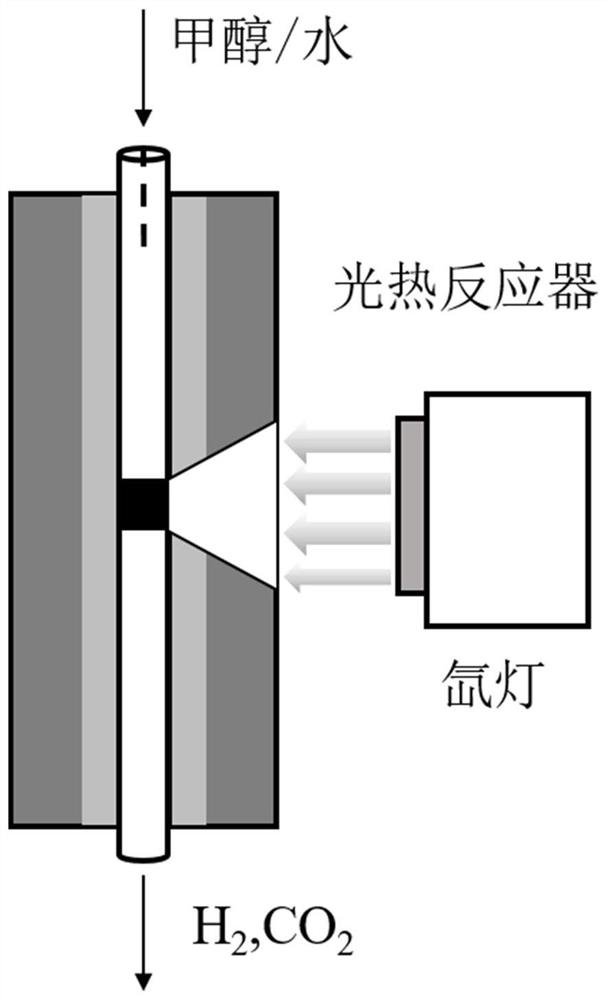

[0049] Example 2: Cu / TiO 2 -CeO 2 Thermocatalytic Performance Test of Composite Porous Oxide Catalysts

[0050] Such as figure 1 As shown, take 8 mg of catalyst loaded on the glass fiber membrane, and place it in a special reaction tube. During the reaction process, methanol / water vapor is continuously delivered in front of the reaction tube, the reactor is set to the required temperature, and the light-transmitting hole is covered. At this time, the composite catalyst only performs methanol reforming hydrogen production under purely thermal conditions at the desired temperature. The reaction conditions are methanol:water=1:1.2, the sampling speed is 4uL / min, and the gas at the outlet of the reactor is sent to a gas chromatograph for detection. Such as Figure 5 As shown, the hydrogen production rate is 22.0mmol / h / g at 275°C and 58.6mmol / h / g at 300°C. Demonstration of Cu / TiO under thermal conditions 2 -CeO 2 The composite oxide catalyst has thermocatalytic properties. ...

Embodiment 3

[0051] Example 3: Cu / TiO 2 -CeO 2 Photothermal Coupling Catalytic Performance Test of Composite Porous Oxide Catalysts

[0052] Take 8 mg of catalyst loaded on the glass fiber membrane, and place it in a special reaction tube. During the reaction process, the methanol / water vapor is continuously transported in front of the reaction tube, the reactor is set to the required temperature, and the xenon lamp is turned on to irradiate sunlight. The special-shaped holes on the wall are introduced into the surface of the catalyst. At this time, the composite catalyst absorbs high-energy photons at the required temperature to perform photothermal coupling reforming to produce hydrogen. The reaction conditions are methanol: water = 1:1.2, the sampling speed is 4uL / min, and the gas at the outlet of the reactor is sent to a gas chromatograph for detection. The hydrogen production rate was 48.1 mmol / h / g at 275°C and 78.8 mmol / h / g at 300°C. Compared with the thermocatalytic hydrogen pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com