High-efficiency compound organic fertilizer based on amino acid substrate

An organic fertilizer and amino acid technology, applied in the direction of organic fertilizer, organic fertilizer preparation, bio-organic part treatment, etc., can solve the problems that bacteria and viruses cannot be killed, microorganisms survive for a long time, and do not have the effect of increasing production, etc., to achieve improvement Redox process, promotion of photosynthesis and chlorophyll formation, good antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

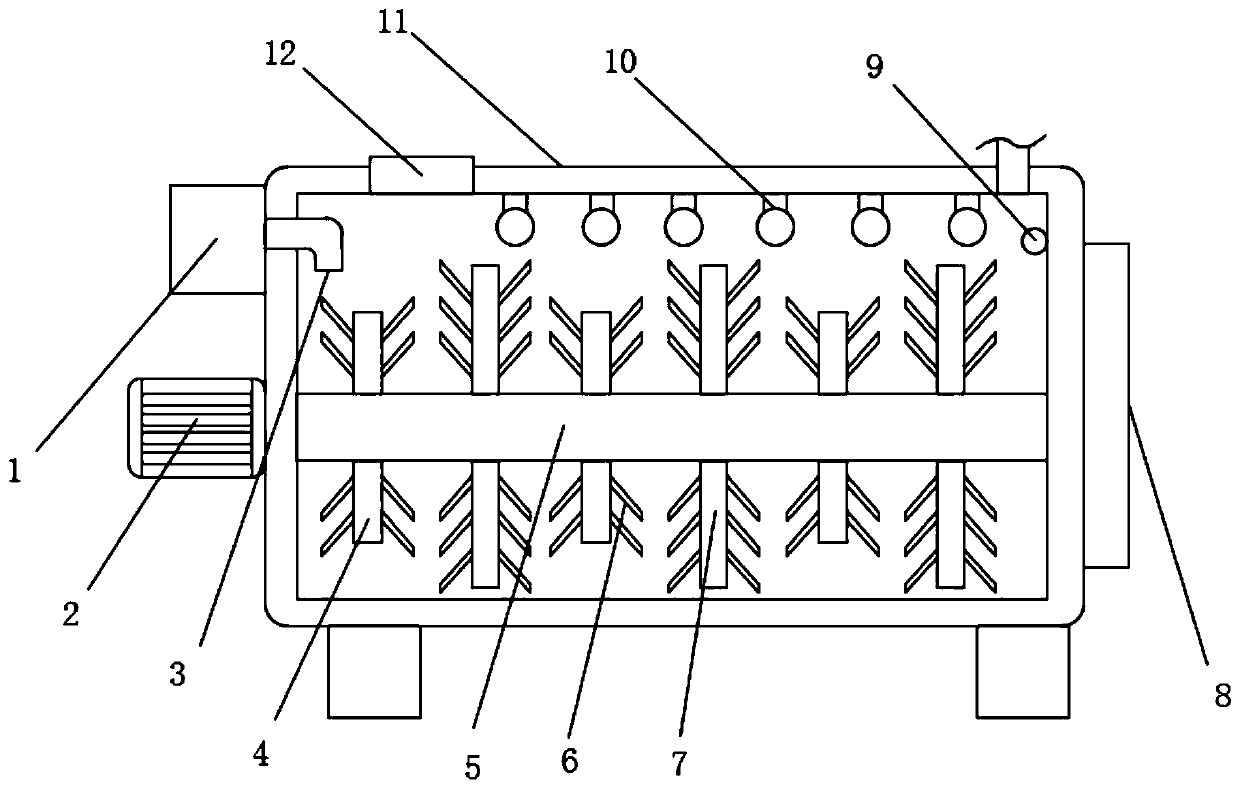

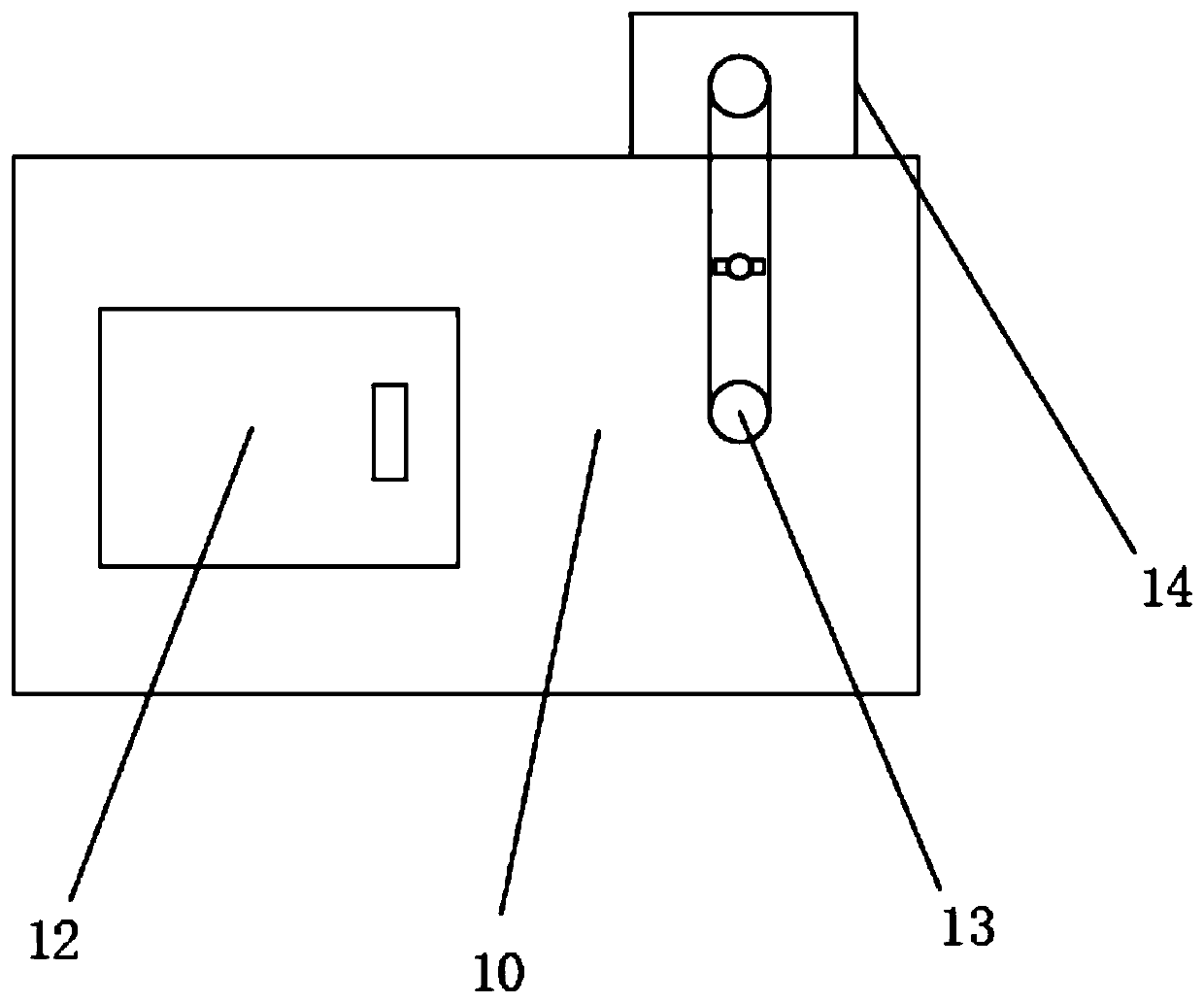

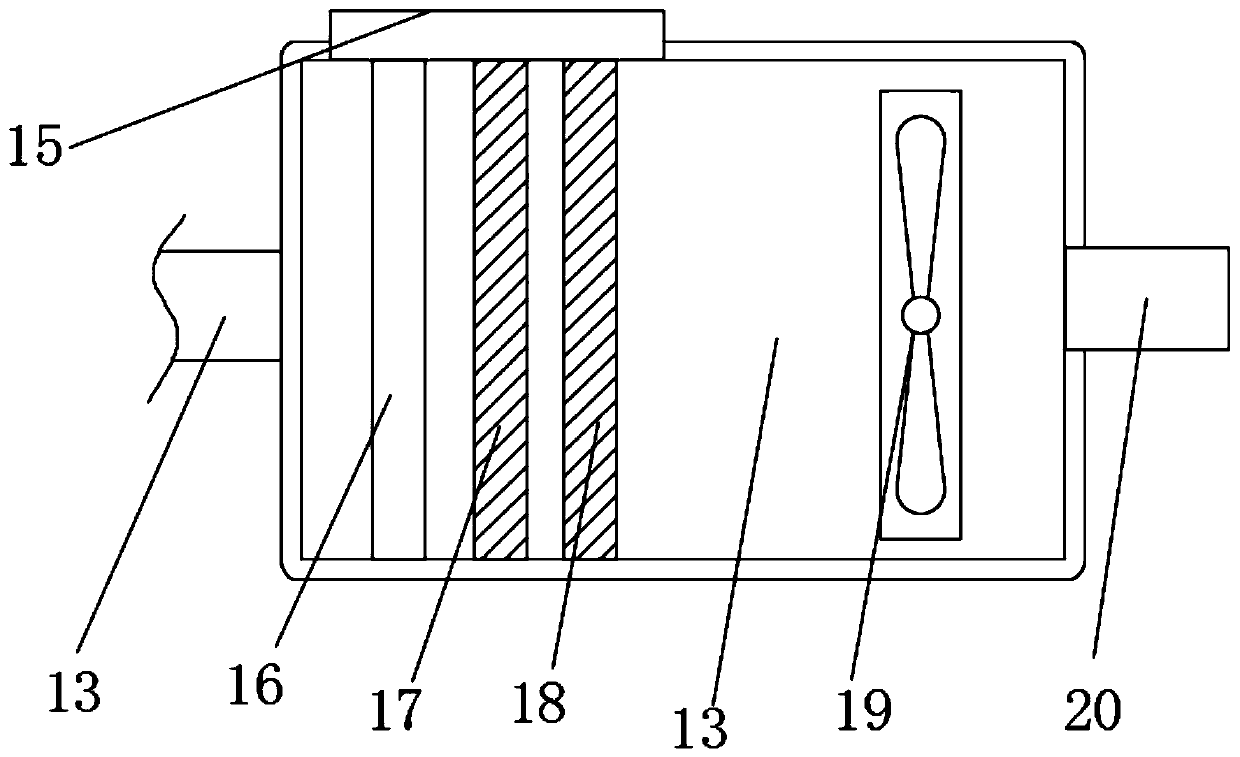

Image

Examples

Embodiment 1

[0036] A high-efficiency compound organic fertilizer based on an amino acid matrix. The compound organic fertilizer is prepared from the following raw materials in parts by weight: 10 parts of a compound amino acid aqueous solution, 10 parts of cow dung, 3 parts of straw, 2 parts of peat soil, 0.5 parts of penicillin slag, 0.5 parts of penicillin residue, 1 part of sugar residue, 1 part of superphosphate, 3 parts of multidimensional compound mold, 5 parts of humic acid, 3 parts of penicillin soil, and 1 part of growth aid;

[0037] Penicillin residues, penicillin residues and sugar residues were all sterilized under high temperature and high pressure at 130°C for 15 minutes;

[0038] Wherein, the compound organic fertilizer is prepared through the following steps:

[0039] Step 1: Hydrolyze the animal hair with edible hydrochloric acid with 20-30% mass content first, add 2-3 kg of dilute hydrochloric acid per kg of animal hair, heat to 60-100°C, and cool the hydrolyzed solutio...

Embodiment 2

[0046] A high-efficiency compound organic fertilizer based on an amino acid matrix, which is prepared from the following raw materials in parts by weight: 10 parts of a compound amino acid aqueous solution, 5 parts of cow dung, 6 parts of straw, 5 parts of peat soil, 1.5 parts of penicillin slag, 1.5 parts of penicillin residue, 3 parts of sugar residue, 2 parts of superphosphate, 7 parts of multidimensional compound mold, 10 parts of humic acid, 5 parts of Pengrun soil, 2 parts of growth aid;

[0047] Penicillin residues, penicillin residues and sugar residues were all sterilized under high temperature and high pressure at 130°C for 15 minutes;

[0048] Wherein, the compound organic fertilizer is prepared through the following steps: the preparation method is the same as in Example 1;

[0049] Wherein, the growth aid is prepared through the following steps: the preparation method is the same as in Example 1.

Embodiment 3

[0051] A high-efficiency compound organic fertilizer based on an amino acid matrix, which is prepared from the following raw materials in parts by weight: 10 parts of a compound amino acid aqueous solution, 5 parts of cow dung, 3 parts of straw, 2 parts of peat soil, 0.5 parts of penicillin slag, 0.5 parts of penicillin residue, 3 parts of sugar residue, 2 parts of superphosphate, 3 parts of multidimensional composite mold, 5 parts of humic acid, 3 parts of penicillin soil, and 1 part of growth aid;

[0052] Penicillin residues, penicillin residues and sugar residues were all sterilized under high temperature and high pressure at 130°C for 30 minutes;

[0053] Wherein, the compound organic fertilizer is prepared through the following steps: the preparation method is the same as in Example 1;

[0054] Wherein, the growth aid is prepared through the following steps: the preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com