Transition metal sulfide modified electrode and preparation method and application thereof

A transition metal, sulfide technology, applied in battery electrodes, circuits, fuel cells, etc., to achieve good catalytic activity, high conductivity, and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

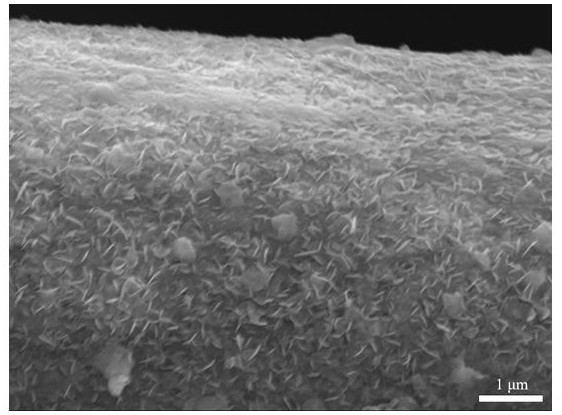

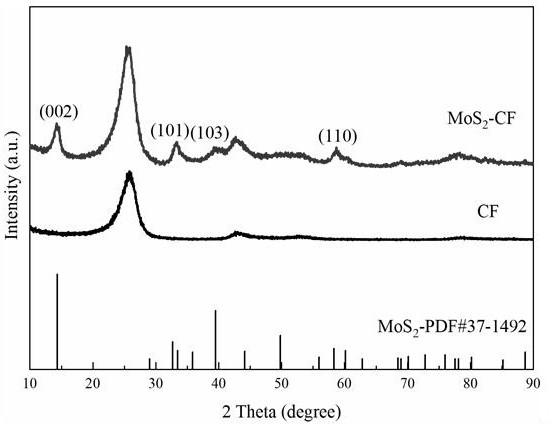

Except (2): Weigh 1.8g of molybdenum powder, add 40mL of deionized water, and carry out magnetic stirring, then add 15mL of 30% hydrogen peroxide, and carry out magnetic stirring in an ice-water bath. After 5 hours, a transparent yellow liquid is obtained. The solution contains molybdenum At this time, the concentration of molybdenum ions in the solution is about 0.34M. Take part of the solution and dilute to constant volume to obtain a solution with a molybdenum ion concentration of 0.1M; use the above-mentioned solution containing 0.1M molybdenum ions as an electrochemical deposition solution, and heat treat the carbon felt As the working electrode, the platinum sheet as the counter electrode, and the saturated calomel electrode as the reference electrode constitute a three-electrode system, followed by constant potential deposition, the deposition voltages are -0.05V, -0.5V, -1V, and the deposition time is 60s, 120s, 180s; place the dried molybdenum disulfide-deposited carbon...

Embodiment 2

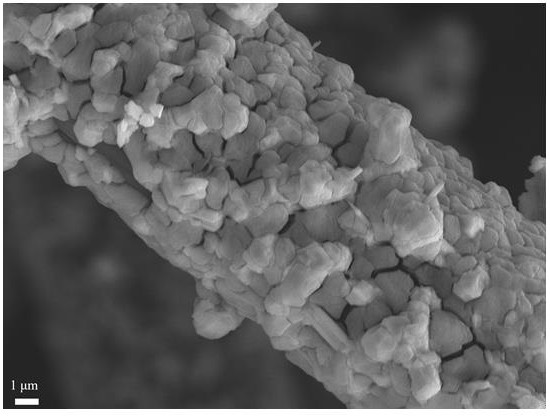

In addition to (2) the loading of transition metal sulfides on the pretreated carbon felt is as follows: dissolve 2.5mmol of thiourea and 2.5mmol of cobalt nitrate hexahydrate in 50mL of deionized water, stir well to obtain a mixed solution, and use it as an electrode Chemical deposition solution; the pretreated carbon felt is used as the working electrode, the platinum sheet is used as the counter electrode, and the Hg / HgO is used as the reference electrode. Within the range, 5, 8, and 10 cycles of electrochemical deposition were carried out at a scan rate of 5 mV / s. After deposition, the carbon felt electrode was taken out, washed repeatedly with alcohol and deionized water, and then vacuum-dried at 80°C for 10 hours to obtain a loaded Cobalt sulfide carbon felt.

[0048] All the other are identical with embodiment 1.

[0049] Example 7

Embodiment 3

(2) Loading of transition metal sulfides on the pretreated carbon felt is as follows: Weigh 0.12 g of potassium ferricyanide and 0.26 g of vitamin C, dissolve them in 40 mL of deionized water, and use vitamin C as a reducing agent. Ensure that the product ferrous disulfide is not oxidized, carry out magnetic stirring, then weigh 1.8g of sodium thiosulfate and dissolve it in 20mL of deionized water, stir to dissolve, add the aqueous sodium thiosulfate solution dropwise to the magnetically stirred ferricyanide Potassium and vitamin C mixed solution; transfer the above mixed solution to a 100mL polytetrafluoroethylene hydrothermal reaction kettle, immerse the pretreated carbon felt in the reaction kettle solution, hydrothermally react at 180°C for 24h, and then take out The reactor was naturally cooled to room temperature to obtain a carbon felt loaded with ferrous sulfide.

[0052] All the other are identical with embodiment 1.

[0053] Example 9

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com