Preparation method of rare earth permanent magnet material

A rare-earth permanent magnet and rare-earth technology, which is applied in the manufacture of magnetic materials, magnetic objects, inductors/transformers/magnets, etc., can solve the problems of high equipment cost and low production efficiency, and achieve improved corrosion resistance and magnet coercive force , the effect of easy diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

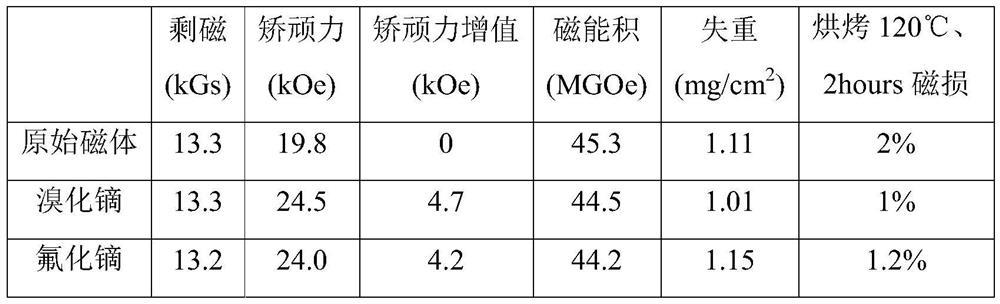

Examples

preparation example Construction

[0020] The preparation method of a kind of rare earth permanent magnet material of the present invention comprises the following steps:

[0021] (1) Prepare R a T b A c m d Composition of sintered magnets; wherein, R is composed of at least one rare earth element (including scandium Sc and yttrium Y), T is composed of Fe and / or cobalt Co, A is composed of boron B and / or carbon C, M is composed of Al, Cu , Zn, In, Si, P, S, Ti, V, Cr, Mn, Ni, Ga, Ge, Zr, Nb, Mo, Pd, Ag, Cd, Sn, Sb, Hf, Ta and W Element composition; a~d represent the atomic percentage based on the alloy, and the range is as follows: 10%≤a≤15%, 3%≤c≤15%, 0.01%≤d≤11%, and b is the balance.

[0022] (2) After cutting the magnet to be sintered into the required shape (thickness not greater than 15mm), wash with acid, alkali or organic solvent; the alkali that can be used includes potassium pyrophosphate, sodium pyrophosphate, potassium citrate, citric acid Sodium, potassium acetate, sodium acetate, potassium ox...

Embodiment

[0027] The embodiment of the preparation method of a kind of rare earth permanent magnet material of the present invention, comprises the following steps:

[0028] (1) Prepare R a T b A c m d A sintered magnet composed of the following substeps:

[0029] (1.1) The composition of the design magnet (Nd 0.74 PR 0.2 Dy 0.06 ) 30 Fe bal co 1.3 Cu 0.15 al 0.3 B 1 ; Among them, bal represents the balance, adding Cu and Al two low-melting point elements, these two elements are easy to distribute in the grain boundary phase, and have the obvious effect of refining the grain. Using the technology of vacuum quick-setting flakes, by adjusting the rotation speed of the rollers and the flow rate of circulating water, and adjusting the cooling rate, the quick-setting flakes with better growth of columnar crystals were finally obtained.

[0030](1.2) The quick-setting tablet of this composition is prepared into powder particles of 2-4 μm by hydrogen breaking and jet milling techn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com