Carbon fiber obtained by electrophoretic deposition-electropolymerization combined modification and resin-based composite material thereof

A technology of electrophoretic deposition and electrophoretic deposition method, which is applied in the field of carbon fiber and its resin-based composite materials, can solve the problems that the mechanical properties of composite materials cannot reach the optimal level, graphene oxide is easy to detach from the fiber surface, and the bonding strength is weak. Achieve effects that are conducive to mechanical interlocking and chemical bonding, improve interface performance, and improve surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Example 1 Preparation of Electrophoretic Deposition-Electropolymerization Combined Modified Carbon Fiber (EPD / EPI-CF) of the present invention

[0052] according to Figure 14 As shown in the flow chart, on the same continuous production line, using water as the medium, first adopt the electrophoretic deposition method to deposit graphene oxide on the surface of the carbon fiber to obtain the graphene oxide coated carbon fiber, and then use the electropolymerization method to oxidize the obtained carbon fiber. The polymer is generated in situ at the surface interface of the graphene-coated carbon fiber, washed with water and dried. Concrete preparation process is as follows:

[0053] 1. Modification of carbon fiber surface by electrophoretic deposition of graphene oxide

[0054] (a) Preparation of electrophoretic solution: the concentration of graphene oxide solution is 200 mg / L, and the pH is adjusted to 11 with sodium hydroxide.

[0055] (b) Electrophoretic deposit...

Embodiment 2

[0063] Example 2 Preparation of Electrophoretic Deposition-Electropolymerization Combined Modified Carbon Fiber Epoxy Composite Material EPD / EPI-CF / EP of the present invention

[0064] Using the EPD / EPI-CF prepared in Example 1, epoxy resin E-51 (available from Wuxi Lanxing Resin Factory), and curing agent DDM (4,4-diaminodiphenylmethane) as raw materials, an electrophoretic Deposition-electropolymerization combined modified carbon fiber epoxy composite material EPD / EPI-CF / EP, the specific preparation process is as follows:

[0065] Using the hand lay-up process, the EPD / EPI-CF and epoxy resin are laid on the mold in a unidirectional way. Under the action of the curing agent DDM, the curing is carried out under the following conditions: the curing pressure is 5MPa, the temperature First at 135°C for 2 hours, then at 175°C for 2 hours, and demoulding to obtain EPD / EPI-CF / EP. In the process, the volume fraction of EPD / EPI-CF in the total raw materials is controlled to be 60%, a...

experiment example 1

[0092] Structural characterization of each modified carbon fiber of Experimental Example 1

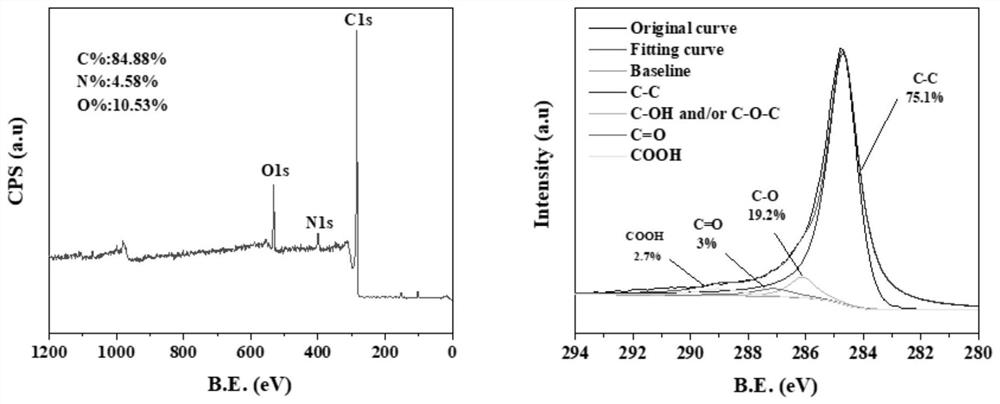

[0093] 1. XPS elemental analysis of untreated carbon fiber CF

[0094] X-ray photoelectron spectroscopy (XPS) was used to analyze the elements on the surface of fibers by Escalab 250Xi instrument from American Thermo Fisher.

[0095] figure 1 It is the XPS elemental analysis of untreated carbon fiber CF. It can be seen that the unmodified carbon fiber surface has fewer active functional groups, lower polarity, and poor wettability to epoxy resin.

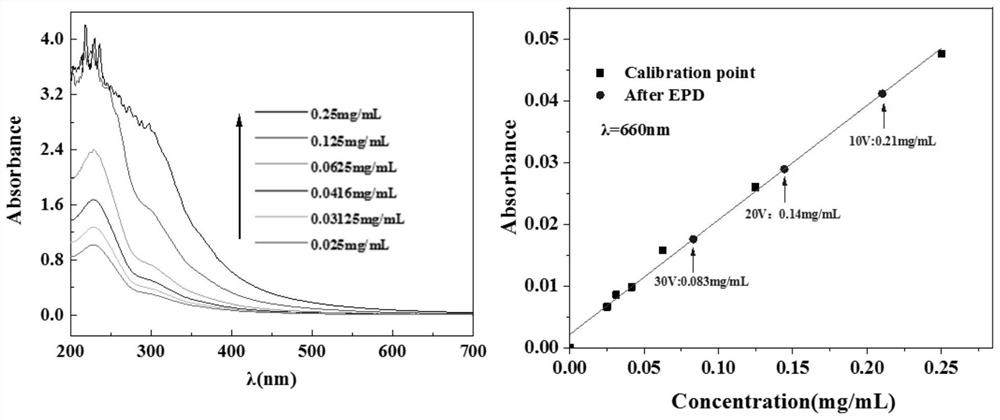

[0096] 2. Characterization of graphene concentration of graphene oxide modified carbon fiber EPD-CF deposited at different voltages

[0097] Ultraviolet-visible absorptiometry (UV-Vis): test with UV3600 UV-Vis-spectrophotometer from Shimadzu Corporation, Japan, and calculate the concentration according to the Beer-Lambert law.

[0098] figure 2 UV-vis absorption curves of EPD-CF deposited for different voltages. It can be seen that gra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com