Preparation method of modified expanded graphite grafted with silicon-phosphorous element

A technology of expanded graphite and modification, which is applied in the field of materials, can solve the problems of deterioration of mechanical properties of polymer materials, destruction of cell structure integrity, and influence of EG flame retardancy, etc., to improve interface compatibility and simple modification method Easy-to-use, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

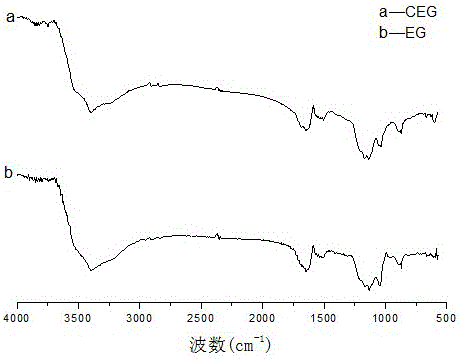

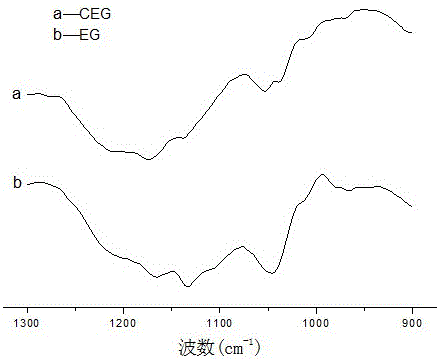

[0032] Step 1: Treatment of expanded graphite with silane coupling agent vinyltriethoxysilane (A-151)

[0033] Prepare 60mL of 90% ethanol aqueous solution, add dilute hydrochloric acid to adjust the pH to 5, then add 2gA-151, mechanically stir at 300r / min at 30°C for 20min, add 20g of expanded graphite with a size of 80 mesh, and heat up to 80°C. 400r / min mechanical stirring for 2 hours, so that the silicon hydroxyl group reacts with the hydroxyl group on the surface of the expanded graphite to form a C-O-Si bond. The reaction equation is as follows:

[0034]

[0035] Step 2: Treatment of A-151 Modified Expanded Graphite with Dilute Phosphoric Acid

[0036] Add 4g of dilute phosphoric acid with a mass fraction of 42.5% to the solution, keep it at 80°C, and stir it mechanically at 400r / min for 2 hours to make it react with silicon hydroxyl groups to form Si-O-P bonds. The reaction equation is as follows:

[0037]

[0038] Then, it was washed and filtered with absolute e...

Embodiment 2

[0041] Step 1: Treatment of expanded graphite with γ-aminopropyltriethoxysilane (KH-550)

[0042] Prepare 50mL of 90% ethanol aqueous solution, add acetic acid to adjust the pH to 5, then add 2g KH-550, stir mechanically at 300r / min at 30°C for 20min, then add 20g of expanded graphite with a size of 100 mesh, heat up to 60°C, 400r / min Mechanical stirring for 4 hours, so that the silicon hydroxyl group reacts with the hydroxyl group on the surface of the expanded graphite to form a C-O-Si bond;

[0043] Step 2: Treat KH-550 modified expanded graphite with dilute phosphoric acid

[0044] Add 4g of dilute phosphoric acid with a mass fraction of 25% to the solution, keep at 80°C, and mechanically stir at 400r / min for 4 hours, so that it can react with silicon hydroxyl groups to form Si-O-P bonds, then wash and filter with absolute ethanol for 5 times, at 80°C Dry in an oven for 12 hours to obtain modified expanded graphite grafted with Si and P elements.

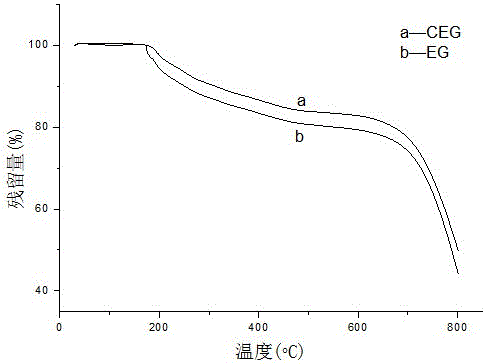

[0045] Table 1 is the...

Embodiment 3

[0049] Same as Example 1, but the silane coupling agent is replaced by a mixture of 2g vinyltriethoxysilane (A-151) and KH560, the molar ratio of the two is 1:1, and other conditions remain unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com