Flame-retardant smoke-suppression polymer composite material and preparation method thereof

A composite material and polymer technology, which is applied in the field of flame-retardant and smoke-suppressing polymer composite materials and their preparation, can solve the problems of poor mechanical properties and decorative effects of materials, low efficiency of flame-retardant and smoke-suppressing, and complex preparation processes, etc., to achieve Excellent mechanical properties and decorative effects, excellent mechanical properties and flame retardancy, and the effect of simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the flame-retardant and smoke-suppressing polymer composite material provided by the present invention comprises the following steps:

[0035] S1: prepare raw materials according to the following mass percentages: 10-15% of three-dimensional carbon felt, 5-10% of zinc stannate, and 75-85% of matrix resin;

[0036] S2: Support zinc stannate on the three-dimensional carbon felt by co-precipitation method, hydrothermal synthesis method or homogeneous precipitation method to prepare a three-dimensional supported zinc stannate carbon felt preform, which accounts for 15-25% of the total weight of the final composite material ;Specifically:

[0037] S21: ultrasonically soak the three-dimensional carbon felt in a solution of ethanol and acetone for 40 minutes, take out and dry to obtain a three-dimensional carbon felt A with clean surface and active groups;

[0038] S22: adding the three-dimensional carbon felt A to the pre-prepared solution system of...

Embodiment 1

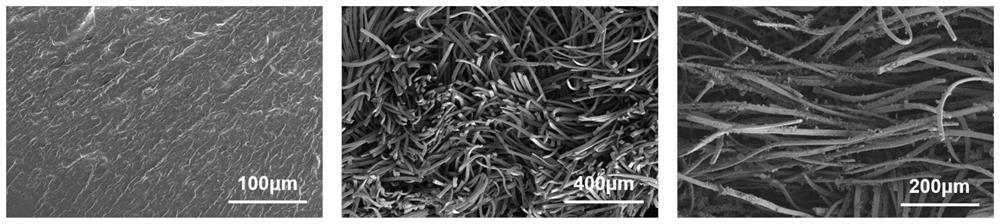

[0053] see attached figure 1 The flame-retardant and smoke-suppressing polymer composite material provided in this embodiment is prepared from three-dimensional carbon felt, zinc stannate, and PP, and the preparation method specifically includes the following steps:

[0054] S1: Preparation of raw materials:

[0055] Three-dimensional carbon felt, zinc stannate, and matrix resin PP were prepared respectively, and the weight percentages of the three were: 10%, 5%, and 85%; wherein, the three-dimensionally loaded zinc stannate carbon felt preform was 15%, and the zinc stannate loading amount was 15%. At 5%, PP resin or monomer is 85%;

[0056] The three-dimensional carbon felt in this embodiment is a polyimide-based carbon fiber, each fiber overlaps each other in a three-dimensional space to form a carbon felt, and the fiber diameter is 10-20 μm.

[0057] PP in this embodiment is a modified resin matrix filled with aluminum hydroxide, modified with magnesium hydroxide (brucite...

Embodiment 2

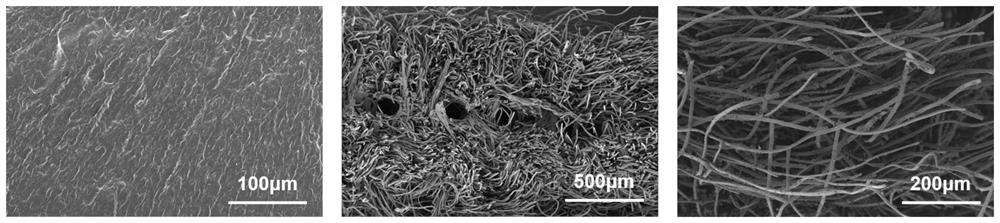

[0068] The flame-retardant and smoke-suppressing polymer composite material and its preparation method provided in this example are basically the same as those in Example 1, and the differences are:

[0069] The composite material is prepared from three-dimensional carbon felt, zinc hydroxystannate, and PP monomer, and the mass percentages of the three are 15%, 10%, and 75% in sequence.

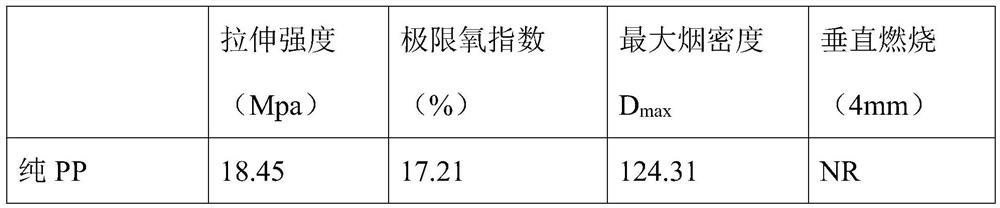

[0070] The samples were subjected to mechanical property test, limiting oxygen index test, UL-94 vertical combustion test, smoke density test and SEM characterization, and the results are shown in the table.

[0071] In the embodiment of the present invention, the interface interaction between the three-dimensional carbon felt and the resin is generated during the in-situ polymerization process, so that the wettability of the three-dimensional carbon felt is improved, the compatibility between the three-dimensional structure and the polymer material interface is enhanced, and the prepared comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com