Quick preparation method for flexible strain sensor on the basis of biaxial drawing technology

A strain sensor and biaxial stretching technology, applied in the field of sensing, to achieve the effect of realizing industrialized production, facilitating large-scale industrialized production, and improving dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

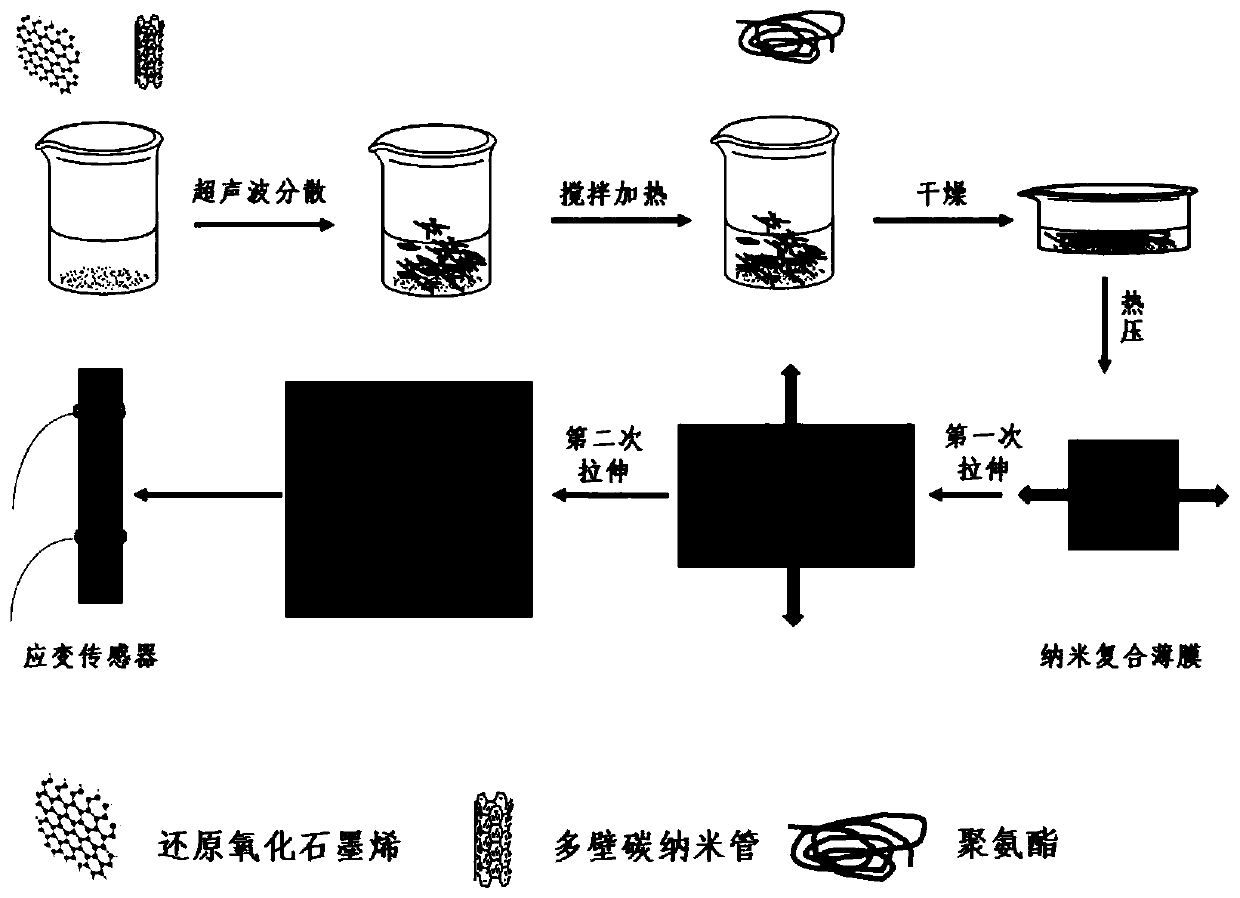

[0034] Such as figure 1 Shown, a kind of rapid preparation method of the flexible strain sensor based on biaxial stretching technology of the present invention comprises the following steps:

[0035] Step 1: Disperse a mixture of 0.04g of reduced graphene oxide and 0.36g of multi-walled carbon nanotubes in 200ml of N,N-dimethylformamide solvent for ultrasonic dispersion for 1 hour;

[0036] Step 2: Then add 19.6g of polyurethane to it, heat and stir at 80°C until the polyurethane is completely dissolved, and then ultrasonically disperse for 2 hours to obtain a polymer nanocomposite solution;

[0037] Step 3: Import the prepared polymer nanocomposite solution into the mold and dry it in an oven at 80°C for 24 hours to obtain the nanocomposite material; The final nanocomposite material is hot pressed for 15 minutes to obtain a nanocomposite material sheet;

[0038] Step 4: Move the nanocomposite sheet into a biaxial tensile testing machine for sequential biaxial stretching und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com