Black body anti-coking ceramic identification coating layer and preparation method thereof

An anti-coking and ceramic technology, applied in coatings, alkali metal silicate coatings, etc., can solve the problems of adverse effects on the physical and mental health of construction workers, poor flow resistance and wear resistance, and affect the service life of substrates, etc., to improve the temperature field Strong and uniform, strong anti-flow velocity wear ability, improve the effect of heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A black body anti-coking ceramic identification coating, the ceramic identification coating is composed of a base layer and a surface layer, the base layer is white, the surface layer is green, and the coating forming the base layer includes zirconia, aluminum oxide, magnesium oxide, fluorosilicic acid Lithium, manganese powder, cerium oxide, lanthanum oxide, sodium silicate, potassium silicate, magnesium hexametaphosphate, aluminum hexametaphosphate, bentonite, clay, cured resin, modified inorganic powder, reactive diluent; coating for forming the surface layer Contains ZS high temperature resistant far infrared radiation coating, aluminum silicate, high temperature binder, bentonite, clay, brown corundum, cordierite, colorant, dispersant; high temperature resistant far infrared radiation coating; the thickness of the base layer is 1-1000μm, the surface layer The thickness of the powder is 0.10-0.15mm. The above powder is ball milled, sieved, and then mixed and stirred ...

Embodiment 2

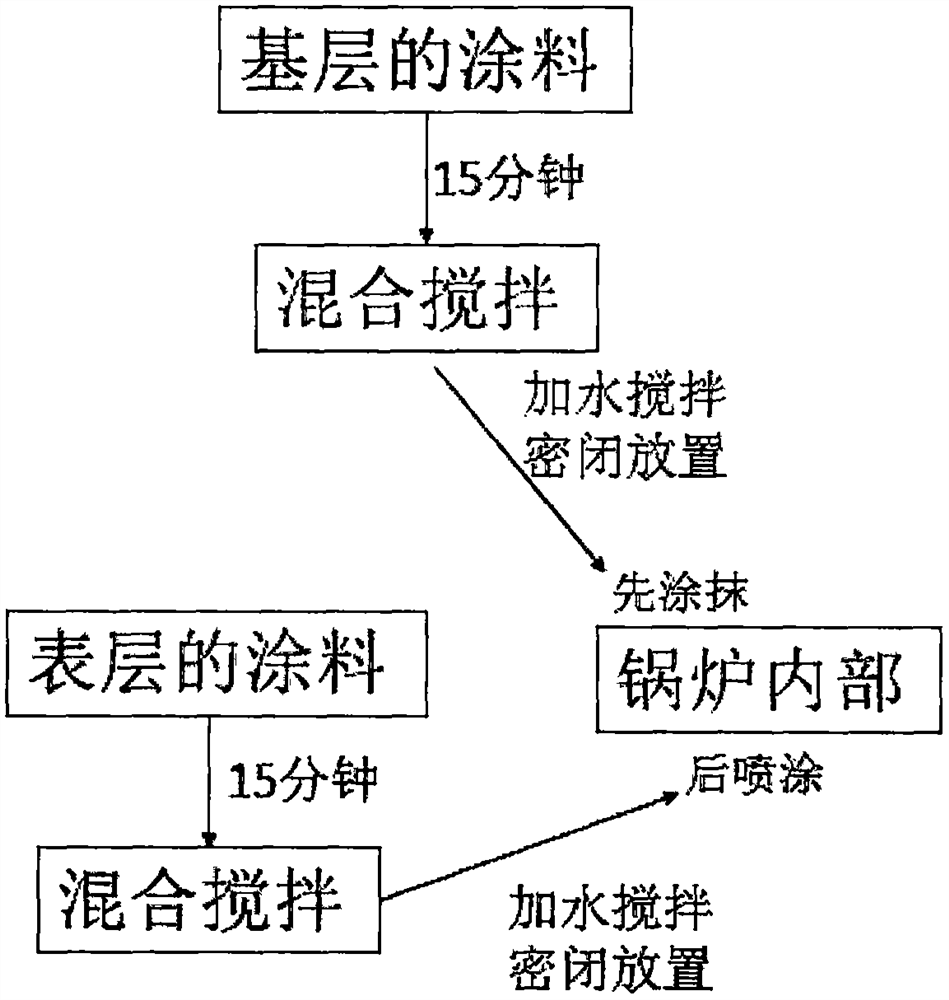

[0020] figure 1 It is a flow chart of a preparation method of a black body anti-coking ceramic identification coating; a preparation method of a black body anti-coking ceramic identification coating, the production method of the ceramic identification coating is: mixing the coating forming the base layer and the coating forming the surface layer respectively Stir for 15 minutes, then add water, stir for 30 minutes, then place it in an airtight place to mix thoroughly to obtain the base coating slurry and the surface coating slurry, and then apply the base coating slurry to the inside of the boiler by smearing. After 24 hours at room temperature The base layer is obtained; then, the surface coating slurry is sprayed on the surface of the base layer by spraying method, and after 48 hours at room temperature, the ceramic identification coating is obtained; if the white base layer is exposed in the boiler, the floating ash on the heating surface is blown by high-pressure wind or wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com