Novel UV photocuring flocking process and flocking equipment for Christmas handicraft

A handicraft, light-curing technology, applied in non-polymer organic compound adhesives, surface pretreatment, devices for coating liquids on surfaces, etc., can solve the problem of slow drying speed of water-based adhesives Slowness, high dependence on experience and skills, to achieve the effect of reducing process production time, improving process production efficiency, and stable process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0060]In one embodiment, the short fiber powder can be prepared by including at least one of vegetable short fiber, animal short fiber, chemical short fiber, etc.; the vegetable short fiber can include cotton short fiber, kapok short fiber, At least one of flax short fiber, ramie short fiber, sisal short fiber, abaca short fiber, etc.; the animal short fiber may include at least one of wool short fiber, rabbit hair short fiber, and mohair short fiber; The chemical short fibers may include at least one of polyester short fibers, nylon short fibers and the like. It should be noted that when the final effect of flocking is a snowflake shape, if the short fiber powder material itself is not white, the short fiber material should be bleached to make the appearance of the snowflake shape more realistic. Further, the short fiber Powder can be dyed to suit shapes other than snowflakes. Preferably, the short fiber powder is cotton short fiber powder, which is low in cost and easy to obtain, ...

Embodiment 1

[0088](1) Mix and dissolve 60 parts by mass of TMPTA and 4 parts by mass of photoinitiator 1173, then add 35 parts by mass of acrylic resin, 0.5 parts by mass of hydroquinone and 0.5 parts by mass of silicone, and stir at a stirring speed of 300r / min 0.5h, get UV curing adhesive;

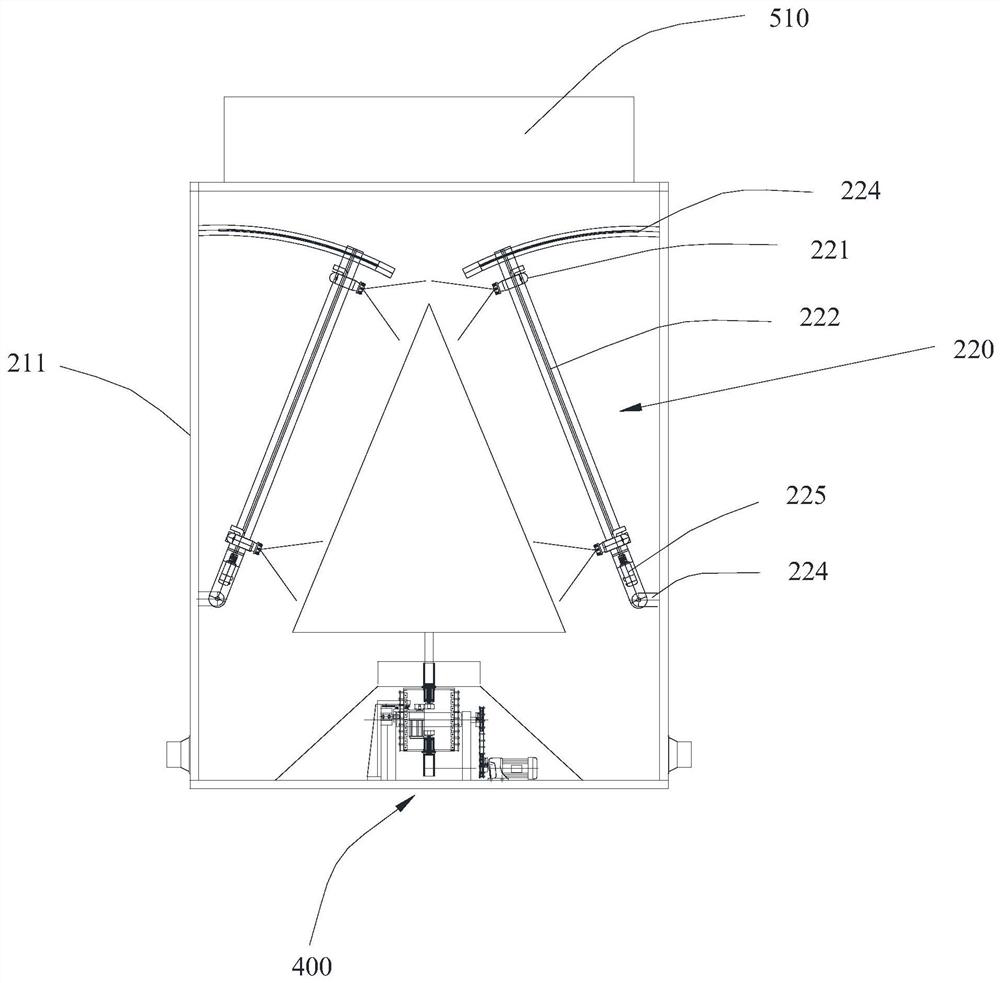

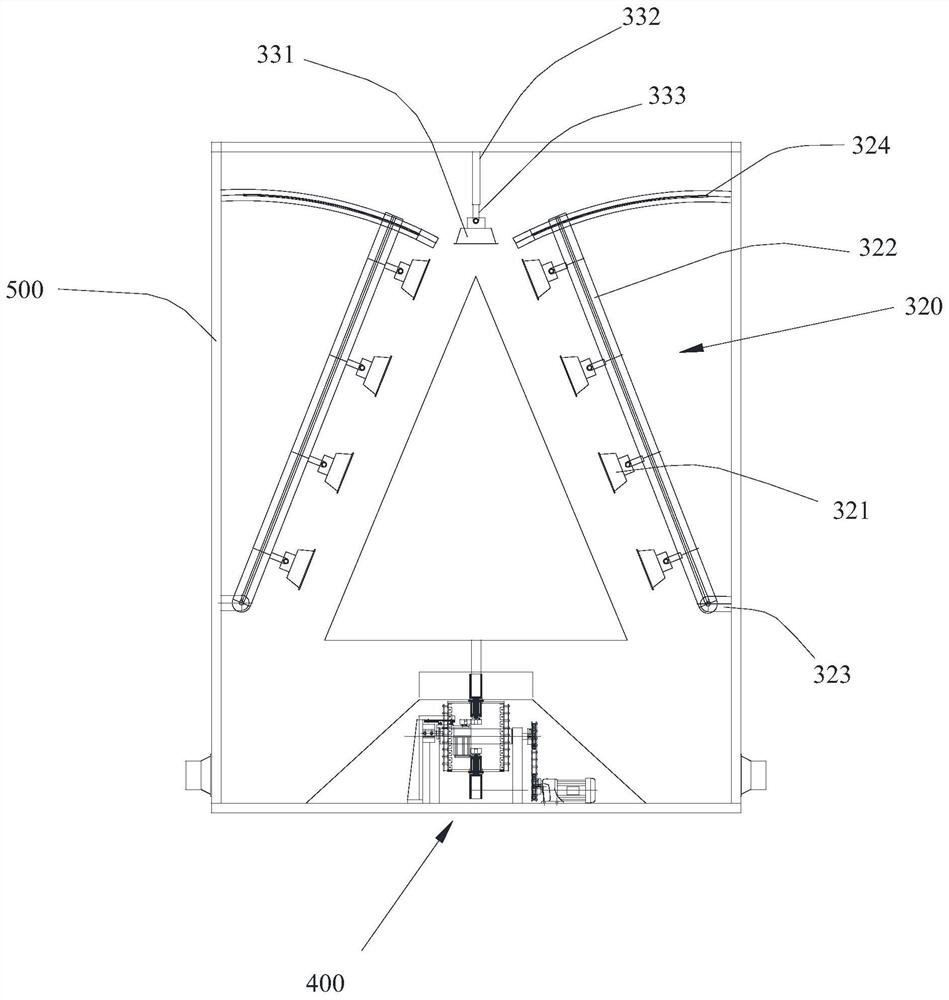

[0089](2) Move the Christmas crafts into the flocking device through the conveyor, control the rotation speed of the Christmas crafts to 5r / min, and control the distance between each spray gun and the surface of the Christmas crafts to be 15cm~60cm, and the spray guns are moving back and forth on the slide rail. Spray UV curing adhesive and short cotton fiber on the Christmas crafts. The mass ratio of UV curing adhesive and short cotton fiber is 3:1 per minute, until the Christmas crafts evenly cover the snowflakes, and the spraying operation is completed;

[0090](3) Move the Christmas crafts into the UV curing device through the conveyor, and control the rotation speed of the Christmas crafts to 5r / min. Under...

Embodiment 2

[0093](1) Mix and dissolve 40 parts by mass of TPGTA and 0.5 parts by mass of photoinitiator 184, and then add 59 parts by mass of epoxy acrylate, 0.1 parts by mass of DEHP, 0.2 parts by mass of p-benzoquinone and 0.2 parts by mass of silicone, at 600r / Stir for 1 hour at a stirring speed of min to obtain a UV curable adhesive;

[0094](2) Move the Christmas crafts into the flocking device through the conveyor, control the rotation speed of the Christmas crafts to 5r / min, and control the distance between the spray guns and the surface of the Christmas crafts to be 15cm~60cm. The spray guns will move back and forth on the slide UV curing adhesive and short cotton fiber are sprayed on Christmas handicrafts. The mass ratio of UV curing adhesive and short cotton fiber is 1:1 per minute, until the Christmas handicrafts are evenly covered with snowflakes and the spraying operation is completed;

[0095](3) Move the Christmas crafts into the UV curing device through the conveyor, and control the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com