Pre cleaning solution recipe for deposit side wall medium of flash memory control grid stack structure

A flash memory and control gate technology, applied in chemical instruments and methods, semiconductor/solid-state device manufacturing, detergent compositions, etc., can solve problems such as consumption and increased production costs, achieve good process stability, increase production, Effect of reducing chemical reagent/DI water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation steps of the present invention are as follows. The first step of cleaning solution preparation steps:

[0022] 1. Prepare the cleaning solution, measure UDV with a graduated cylinder, and pour it into the clean solution cleaning tank.

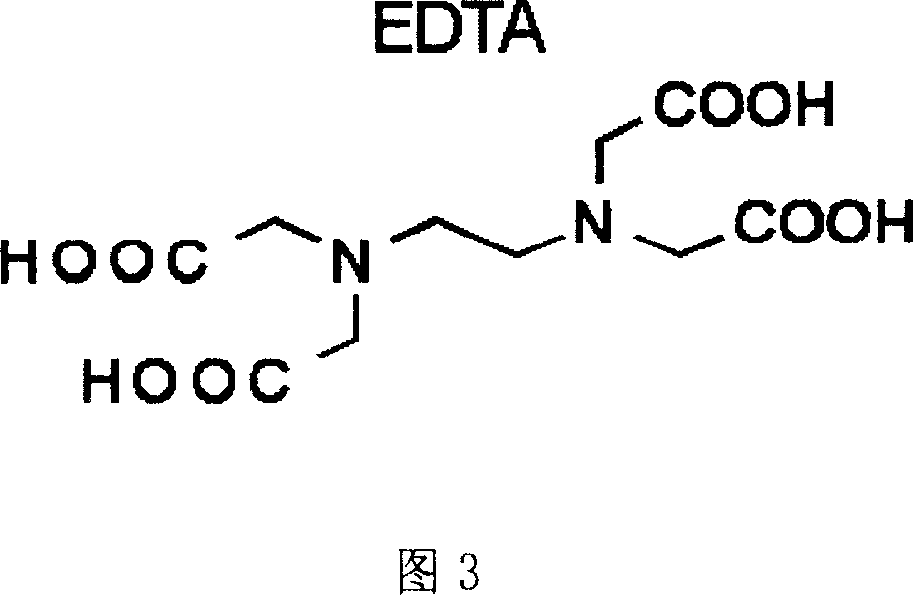

[0023] 2. Accurately measure 50ppm ethylenediaminetetraacetic acid with a graduated cylinder, and slowly pour it into the above-mentioned high-purity water cleaning tank.

[0024] 3. Accurately measure TMAH with a measuring cylinder, the weight content is 10%, and slowly pour it into the cleaning tanks of Sheng 1 and 2 above.

[0025] 4. After the above steps 1 to 3 are completed, let the various ingredients be mixed evenly and wait for at least half an hour before they can be used for process cleaning.

[0026] 5. The cleaning solution is heated to the temperature required by the process, the typical temperature is 35°C.

[0027] The second step is to perform pre-cleaning before depositing the sidewall die...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com