Cleaning liquor for diffusion, oxidation and epitaxial process

A technology of cleaning solution and epitaxy process, which is applied in the directions of cleaning methods, chemical instruments and methods, cleaning methods and utensils using liquids. Process production time, the effect of improving production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The cleaning solution preparation steps of the present invention are as follows.

[0029] 1. Prepare the cleaning solution, measure it with a graduated cylinder (volume ratio is 70%), and pour it into a clean solution cleaning tank.

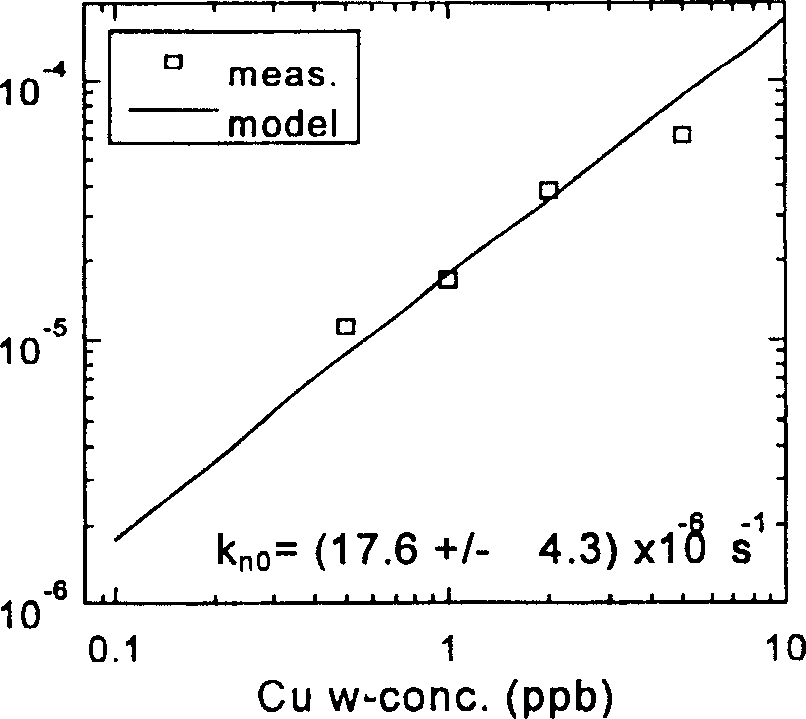

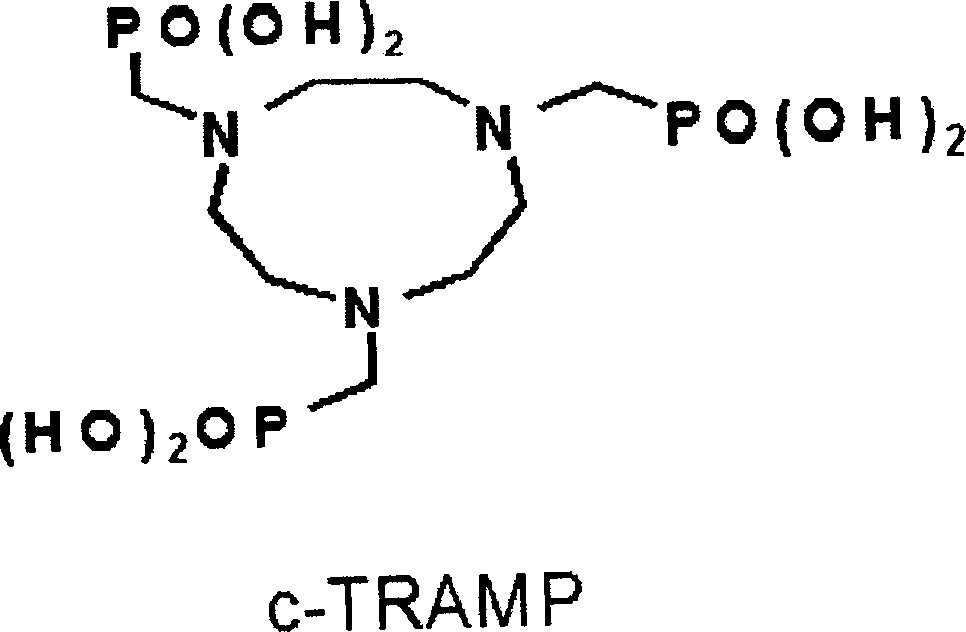

[0030] 2. Accurately measure 5-50ppm c-TRAMP with a measuring cylinder, and slowly pour it into the Shenggao pure water cleaning tank.

[0031] 3. Accurately measure TMAH with a graduated cylinder, the content is 5-200ppm, and slowly pour it into the cleaning tank of Sheng 1 and 2 above.

[0032] 4. Measure a certain amount of ammonia water (29% NH 3 h 2 O), the content is 3%, slowly pour into the above-mentioned Sheng 1, 2, 3,

[0033] 4 Clean the tank.

[0034]5. After the above steps 1 to 4 are completed, let the various ingredients be mixed evenly and wait for at least half an hour before they can be used in the process.

[0035] art cleaning.

[0036] 6. The OZONE produced by the ozone generator enters the cleaning tank through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com