Waterborne polyurethane-polyacrylate resin as well as preparation method and application thereof

A water-based polyurethane and polyacrylate technology, used in coatings, metal-free paints, etc., can solve problems such as poor stone-strike resistance of paint films, and achieve improved stone-strike resistance, good solvent responsiveness, and excellent The effect of stone resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

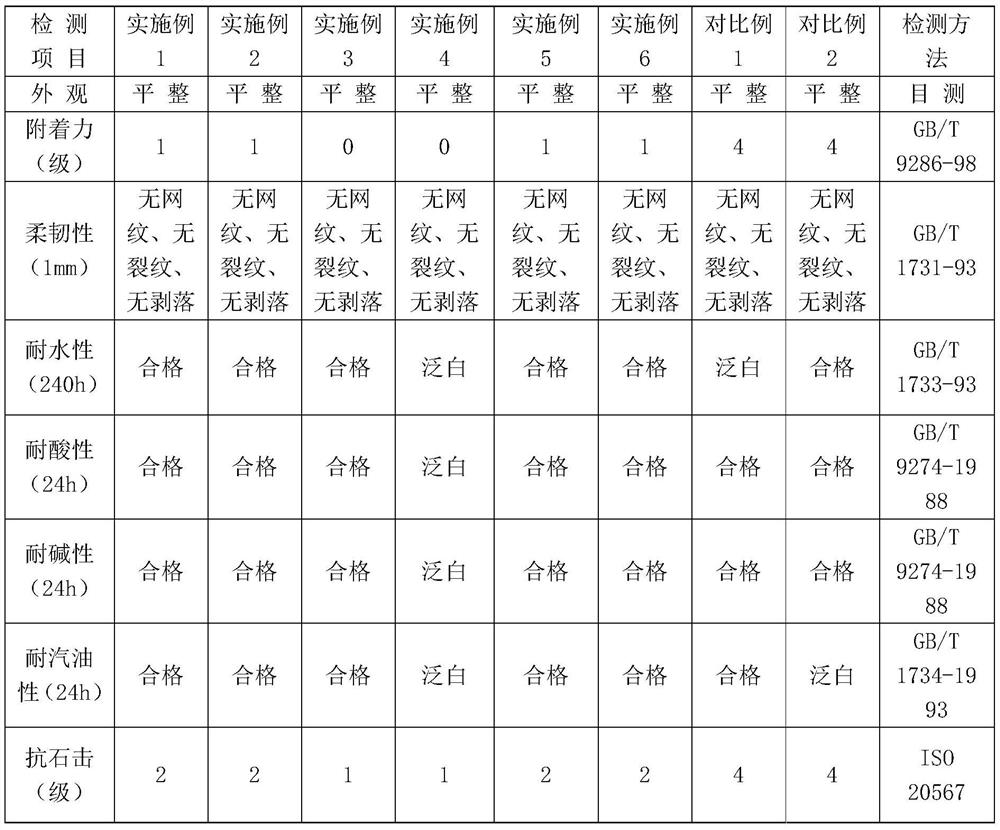

Examples

Embodiment 1

[0036] A kind of aqueous polyurethane-polyacrylate resin, comprises the raw material of following parts by weight:

[0037] Waterborne polyurethane prepolymer: 403 parts;

[0038] Tert-butyl hydroperoxide: 3 parts;

[0039] Methyl methacrylate: 12 parts;

[0040] Divinylbenzene: 2 parts;

[0041] Ethyl acrylate: 10 parts;

[0042] Butyl methacrylate: 15 parts;

[0043] Wherein, described aqueous polyurethane prepolymer comprises the raw material of following parts by weight:

[0044] Saturated polyester diol: 30 parts;

[0045] Hexamethylene diisocyanate: 15 parts;

[0046] Isophorone diisocyanate: 15 parts;

[0047] Methyl isobutyl ketone: 15 parts;

[0048] Dimethylolbutyric acid: 8 parts;

[0049] Glycerol: 3 parts;

[0050] Linoleic acid: 3 parts;

[0051] Organic bismuth: 2 parts;

[0052] 1.6-hexanediol: 8 parts;

[0053] Acrylamide: 3 parts;

[0054] Styrene: 26 parts:

[0055] Lauryl acrylate: 10 parts;

[0056] Glycidyl methacrylate: 6 parts;

[0057]...

Embodiment 2

[0064] A kind of aqueous polyurethane-polyacrylate resin, comprises the raw material of following parts by weight:

[0065] Waterborne polyurethane prepolymer: 351 parts;

[0066] Lauroyl peroxide: 3 parts;

[0067] Butyl methacrylate: 16 parts;

[0068] Diacetone acrylamide: 3 parts;

[0069] Ethyl acrylate: 10 parts;

[0070] Wherein, described aqueous polyurethane prepolymer comprises the raw material of following parts by weight:

[0071] Unsaturated polycarbonate diol: 32 parts;

[0072] Cyclohexane dimethylene diisocyanate: 25 parts;

[0073] Hexamethylene diisocyanate trimer: 2 parts;

[0074] Butanone: 15 parts;

[0075] Polyethylene glycol: 15 parts;

[0076] Trimethylolpropane monoallyl ether: 8 parts;

[0077] Soybean oleic acid: 2 parts;

[0078] Tin dilaurate: 2 parts;

[0079] Hexamethylenediamine: 5 parts;

[0080] Lauryl acrylate: 5 parts;

[0081] n-butyl acrylate: 18 parts:

[0082] Styrene: 12 parts;

[0083] Tert-butyl acrylate: 6 parts;

[...

Embodiment 3

[0090] A kind of aqueous polyurethane-polyacrylate resin, comprises the raw material of following parts by weight:

[0091] Waterborne polyurethane prepolymer: 364.5 parts;

[0092] Azobisisobutyronitrile: 5 parts;

[0093] Lauryl acrylate: 5 parts;

[0094] Ethyl acrylate: 3 parts;

[0095] Methyl methacrylate: 20 parts;

[0096] Wherein, described aqueous polyurethane prepolymer comprises the raw material of following parts by weight:

[0097] Saturated polycarbonate diol: 28 parts;

[0098] Tetramethylxylylene diisocyanate: 15 parts;

[0099] Diphenylmethane diisocyanate: 15 parts;

[0100] Butyl acetate: 13 parts;

[0101] 1. Sodium 4-butanediol-2-sulfonate: 10 parts;

[0102] Glycidyl tertiary carbonate: 3 parts;

[0103] Pentaerythritol: 2 parts;

[0104] Dibutyl tin acetate: 3.5 parts;

[0105] 1.4-butanediol: 10 parts;

[0106] Methyl methacrylate: 15 parts;

[0107] Butyl methacrylate: 10 parts:

[0108] Cyclohexyl acrylate: 5 parts;

[0109] 2-hydroxye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com