Method for carrying out surface activation treatment on surface of copper alloy

A surface activation treatment, copper alloy technology, applied in the field of activation, can solve the problems that it is difficult to ensure the bonding force between copper/copper alloy materials and the coating, rust or other dirt is not completely removed, and production efficiency is restricted, so as to achieve rapid oxidation removal layer, improve the effect of insufficient activation or excessive etching, and enhance the bonding force of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for carrying out surface activation treatment on a copper alloy surface, comprising the following steps:

[0036] The first step: first transfer the copper alloy to be electroplated to the degreasing solution and perform electrolytic degreasing at room temperature. The degreasing solution is strongly alkaline. The purpose of degreasing and degreasing. The degreasing solution includes degreasing powder with a concentration of 70g / L, and the Baume degree of the degreasing solution is 8°Bé. After the electrolytic degreasing step is completed, the copper alloy to be electroplated after electrolytic degreasing is subjected to three-stage water washing at room temperature To wash away the residual degreasing liquid. Among them, the degreasing powder was purchased from Wenzhou Zhengbang Chemical Co., Ltd., the model is CF-W318, and the degreasing powder can be obtained from commercial channels, and the source of the degreasing powder is not restricted.

[0037] Step...

Embodiment 2-5

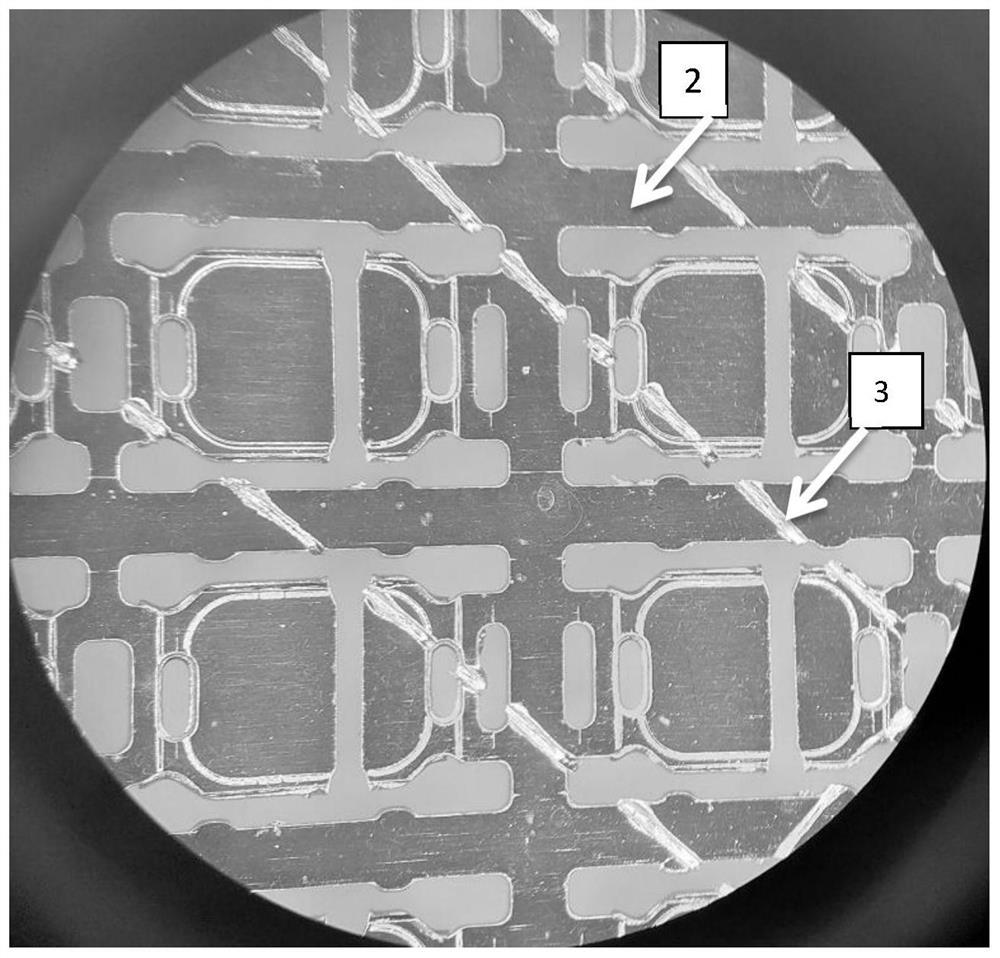

[0043] The difference between Embodiments 2-5 and Embodiment 1 lies in that the parameters of each step are different. See Table 1 for related detailed parameters. The effect of the copper alloy used in embodiment 2-5 after the activation of the electroplated part is also as figure 2 As shown (because the activation effect of the electroplated product obtained in embodiment 2-5 is weak with the difference of embodiment 1, the electroplated product obtained in embodiment 2-5 is placed under the microscope of the same magnification to obtain a picture with high similarity, for simplification read, adopt figure 2 as an activation effect description).

[0044] 1. The parameter summary of each step of table 1 embodiment 1-5

[0045]

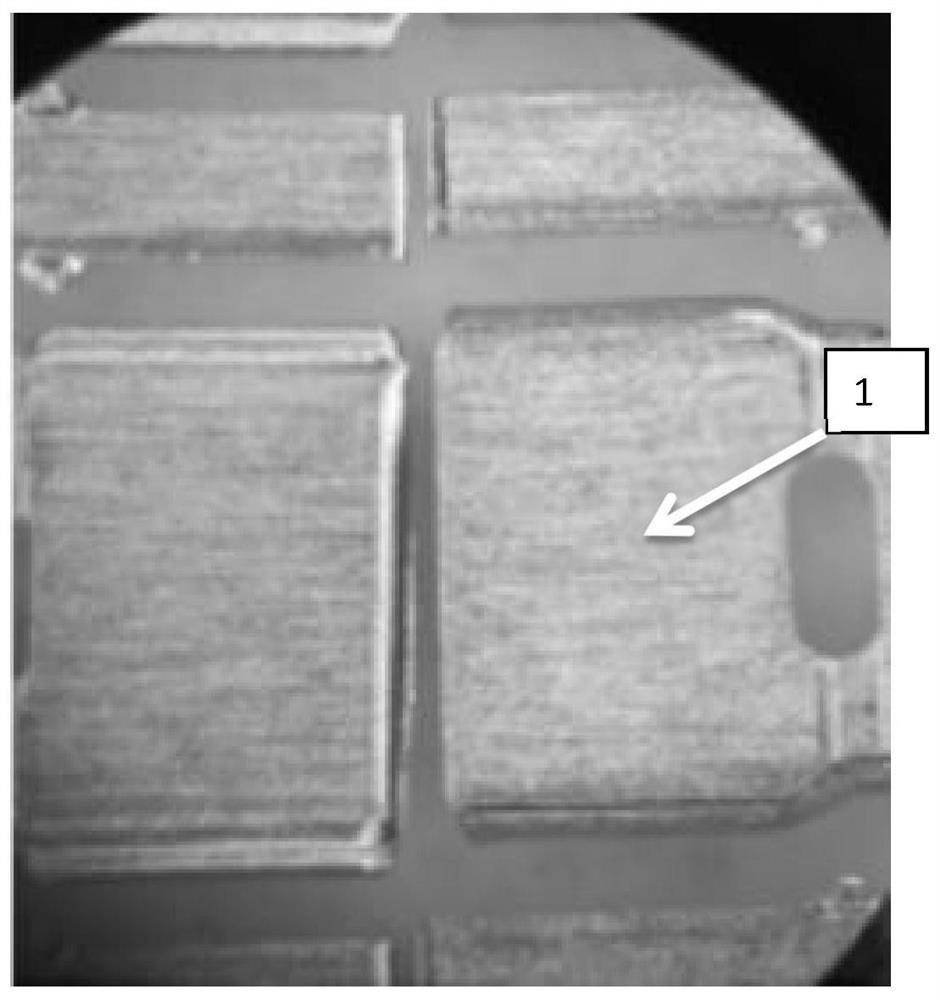

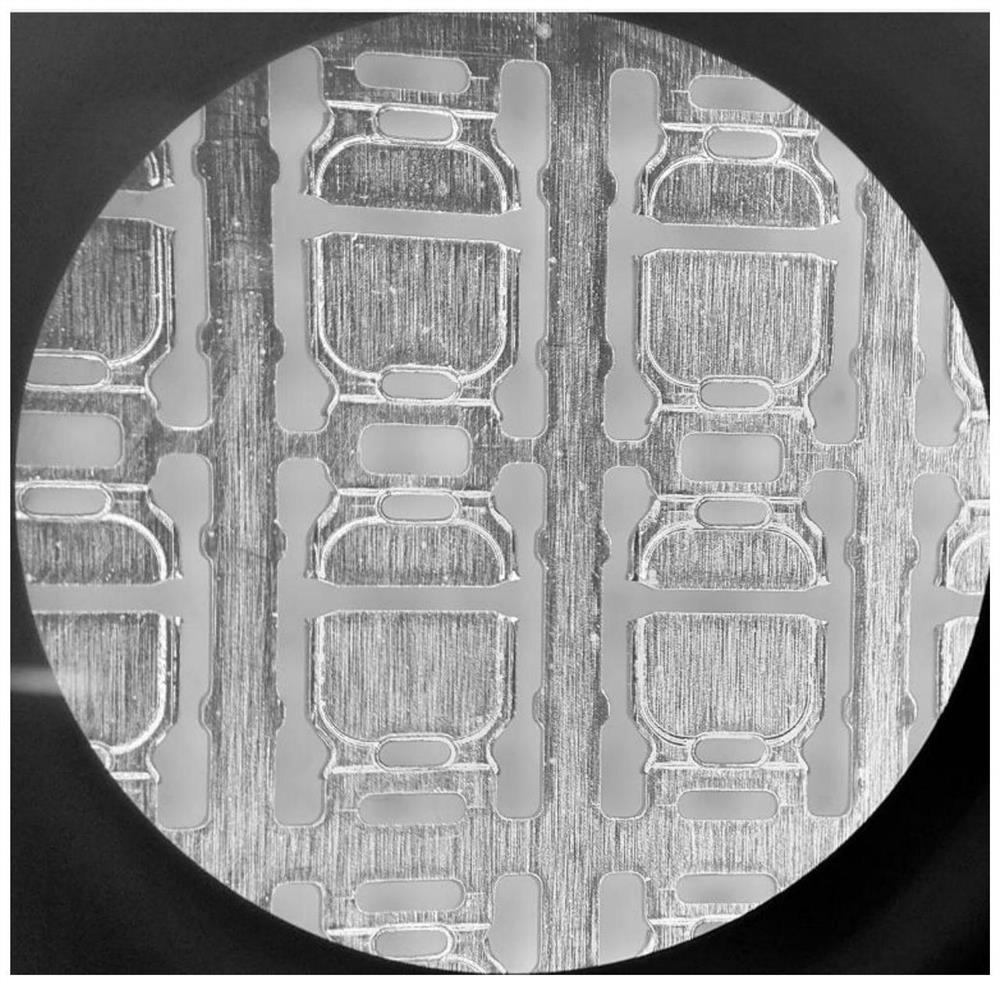

[0046] See Table 1, from figure 1 It can be seen that there is a thick oxide layer on the surface of the copper alloy to be electroplated, and the measured surface roughness Ra is 2.5-5 μm, which is obtained under the action of the activation...

Embodiment 6-10

[0052] The difference between embodiments 6-10 and embodiment 1 is that the copper alloy parts to be electroplated come from different manufacturers, the components of the copper alloy parts to be electroplated from different manufacturers, and the proportioning between the components are different, as shown in embodiments 6-10. The copper alloy parts to be electroplated are from manufacturers A, B, C, D, and E, and they are only illustrative, just to illustrate that this application can adapt to different copper materials and copper alloy materials. The copper alloy parts to be electroplated used in Examples 6-10 were activated. The effect of the copper alloy used in embodiment 6-10 after the activation of the electroplated part is also as figure 2 shown. See Table 2 for related detailed parameters.

[0053] Table 2 Example 6-10 Main components and proportions of copper alloy parts to be electroplated from different manufacturers

[0054]

[0055] See Table 2, from f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com