Anti-sticking coating, carbon-based boat and preparation method thereof

An anti-stick coating, carbon-based technology, used in coatings, lighting and heating equipment, metal material coating processes, etc., can solve problems such as affecting product quality, high labor costs, and inability to solve reuse, and achieve stable improvement. properties and service life, improving density and flatness, and inhibiting the effect of interdiffusion of elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

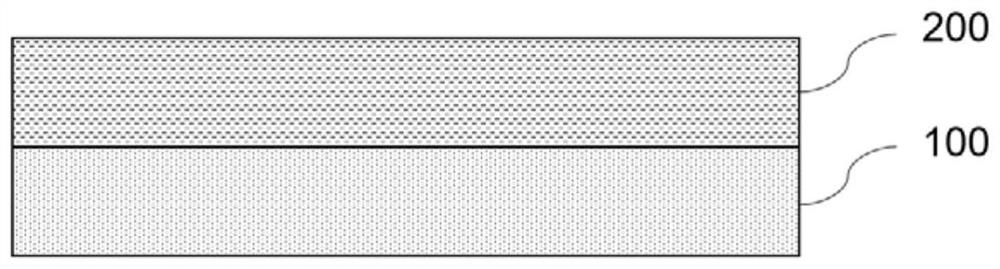

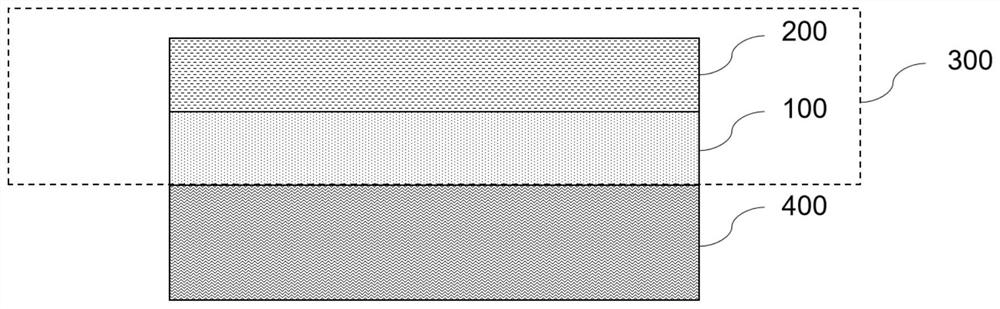

[0052] According to the method for preparing the above-mentioned carbon-based boat according to the embodiment of the present invention, by spraying chromium group elements on the surface of the carbon-based boat substrate to form a transition layer containing chromium group elements, the density and smoothness of the coating can be effectively improved, and The transition layer has high bonding strength with the carbon-based boat substrate, and then at least one of alumina, zirconia and rare earth oxides is sprayed on the overcoating layer to form an intermediate layer containing alumina, zirconia and rare earth oxides on the transition layer. At least one of the working layers can not only improve the bonding strength between the anti-stick coating and the boat, but also enhance the isolation ability of the coating. When the carbon-based boat is used for cemented carbide sintering, the transition layer in the anti-stick coating not only has good bonding strength with the carbon...

Embodiment 1

[0056] Step 1: Use acetone to clean the carbon-based boat substrate to ensure that the oil on the sprayed surface is completely removed;

[0057] Step 2: Dry the stain-removed carbon-based boat substrate at a drying temperature of 105°C to ensure that the carbon-based boat substrate is dry;

[0058] Step 3: Sandblasting the inner surface of the carbon-based boat substrate, sandblasting process: the pressure is 1.6bar, and the sandblasting particles are 80 mesh white corundum;

[0059] Step 4: Spraying metallic chromium on the surface of the carbon-based boat substrate by spraying equipment, so as to form a transition layer containing metallic chromium on the surface of the carbon-based boat, and the thickness of the chromium coating is 22 μm. The main air flow rate is 35L / min, the auxiliary air flow rate is 5L / min, the powder feeding pressure is 0.6bar, the powder feeding speed is 10g / min, and the distance between the spray gun and the substrate is 11cm. The muzzle moving spe...

Embodiment 2

[0064] Step 1: Use alcohol to clean the carbon-based boat substrate to ensure that the oil on the sprayed surface is completely removed;

[0065] Step 2: Dry the stain-removed carbon-based boat substrate at a drying temperature of 100°C to ensure that the carbon-based boat substrate is dry;

[0066] Step 3: Sandblasting the inner surface of the carbon-based boat substrate, the sandblasting process: the pressure is 2.0bar, and the sandblasting particles are 120 mesh white corundum;

[0067] Step 4: Spraying metal tungsten on the surface of the carbon-based boat substrate with spraying equipment to form a transition layer containing metal tungsten on the surface of the carbon-based boat substrate, and the thickness of the tungsten coating is 45 μm. The main air flow rate is 43L / min, the auxiliary air flow rate is 9L / min, the powder feeding pressure is 0.62bar, the powder feeding speed is 16g / min, and the distance between the spray gun and the substrate is 10cm. The muzzle movin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com