Hydrogen ironmaking method and device

A hydrogen and hydrogen-rich technology, applied in microwave heating and other directions, can solve the problems of inability to achieve pure hydrogen smelting and carbon emissions, and achieve the effects of increasing activation energy, reducing consumption, and reducing CO2 emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

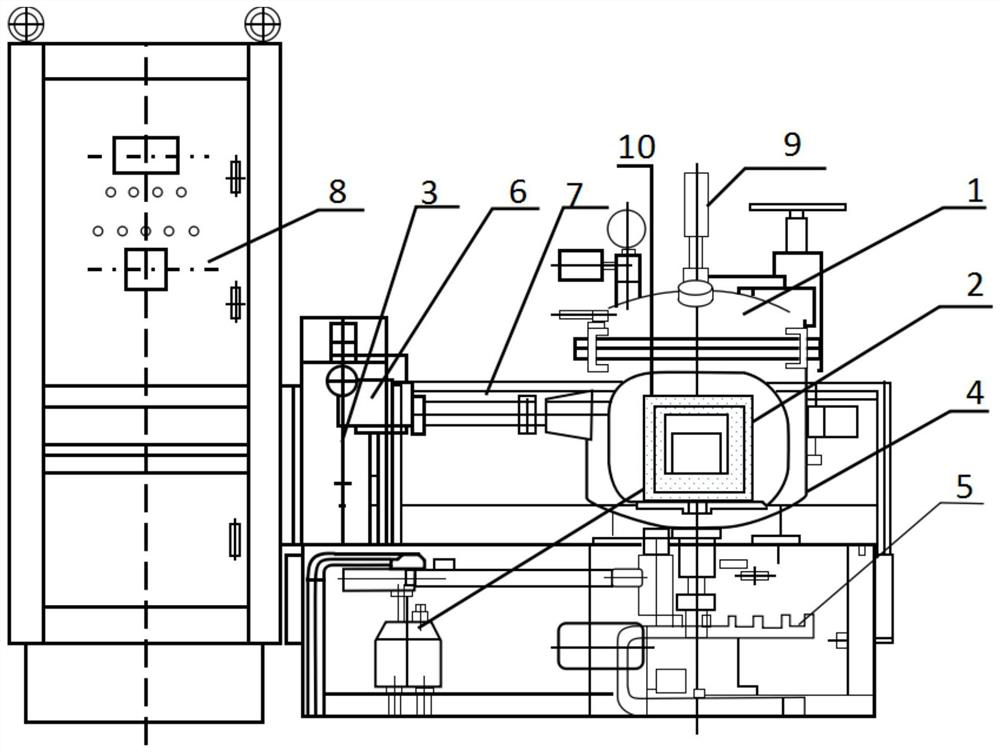

Image

Examples

Embodiment 1

[0061] A method of microwave pure hydrogen gas ironmaking, comprising the following steps:

[0062] Step 1. Weigh 200g of ilmenite, 8g of sodiumizing agent, 8g of additive silicon carbide, among the sodiumizing agent: 2g of sodium silicate, 3g of sodium chloride, and 3g of sodium borate.

[0063] Step 2, adopt method one of pretreatment method to carry out ore raw material pretreatment:

[0064] Titanium concentrate particle size below 200 mesh accounts for 75% - 80%. Grind it to prepare ilmenite-containing fine powder with a particle size of 4mm, and dry the prepared ilmenite-containing fine powder at a drying temperature of 100°C for a drying time of 3 hours.

[0065] Step 3. Make silicon carbide into a sheet and lay it on the bottom of the crucible, mix sodium silicate, sodium chloride, sodium borate and ferro-titanium powder into the crucible in the reactor, first pass nitrogen protection, and use microwave The irradiation power is 1kw, the frequency is 2.45GHZ, and the ...

Embodiment 2

[0071] A method for making iron with microwave hydrogen-rich gas, comprising the following steps:

[0072] Step 1. Weigh 200g of iron ore and 40g of carbon powder (carbonaceous reducing agent), weigh 6g of sodium hydroxide (sodiumizing agent) and store it dry, and weigh 7g of zinc oxide (additive) soot.

[0073] Step 2, adopt the side two of pretreatment method to carry out iron ore pretreatment:

[0074] Crush and grind the iron ore to below 200 mesh and mix it with carbon powder, use sodium silicate as a binder to make pellets with a diameter of 3 cm, and dry the prepared pellets at 120°C for 4 hours.

[0075] Step 3, mix the pellets, sodium hydroxide (sodiumizing agent) and zinc oxide (additive) obtained in step 1 and add them into the crucible, first feed nitrogen protection, and use microwaves to irradiate with a power of 2kw and a frequency of 2.45GHZ, measure the temperature with an infrared thermometer, stop feeding nitrogen when the temperature in the reactor reaches...

Embodiment 3

[0079] A method of microwave pure hydrogen gas ironmaking, comprising the following steps:

[0080] Step 1, take by weighing 200g of iron ore concentrate, 11g of additive graphite powder, 8g of sodium hydroxide;

[0081] Step 2, adopt method one of pretreatment method to carry out ore raw material pretreatment:

[0082] The particle size of iron ore concentrate is below 200 mesh, accounting for 75%-80%. Grind it to prepare iron-containing fine powder with a particle size of 5mm, and dry the prepared iron fine powder at a drying temperature of 115°C for a drying time of 2.5 hours.

[0083] Step 3. Mix the additive graphite powder, sodium hydroxide sodium hydroxide and iron fine powder into the crucible, first pass nitrogen protection, use microwave irradiation power of 0.8kw, frequency of 2.45GHZ, measure with infrared thermometer temperature, when the temperature in the reactor reaches 1200°C, stop feeding nitrogen, and feed hydrogen, the hydrogen pressure is set to 0.1MPa, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com