High-cerium-content scandium-doped gadolinium iron garnet magneto-optical crystal as well as preparation method and application thereof

A magneto-optical crystal and garnet technology, which is applied in the field of high-cerium-containing scandium-doped gadolinium-iron garnet magneto-optic crystal and its preparation, can solve the problems of easy corrosion of solvents, harmfulness to human body and environment, etc., and achieve excellent magneto-optical performance, Good crystallinity and good optical uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

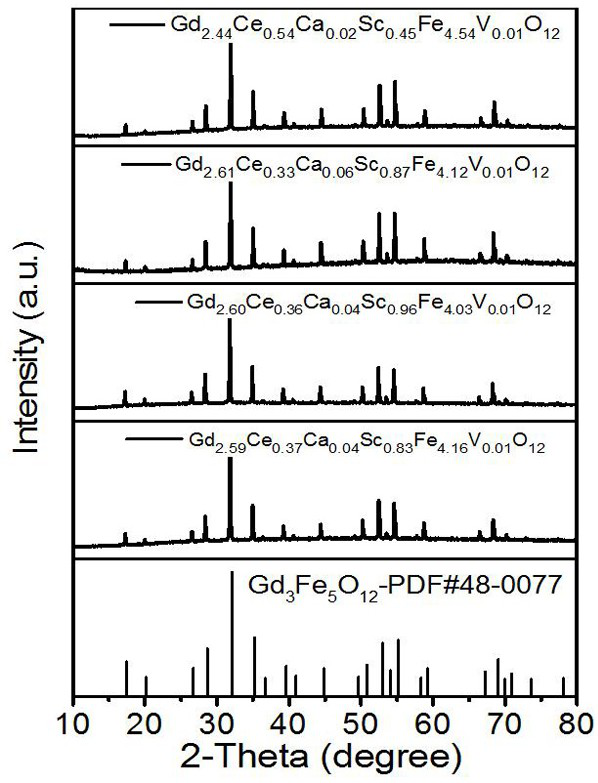

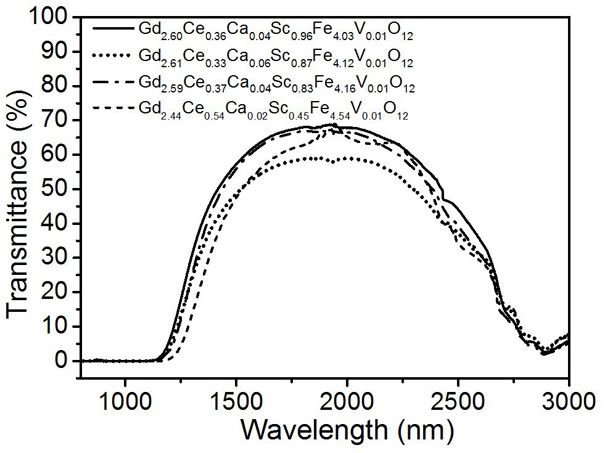

[0027] Magneto-optic crystal Gd with high cerium content and scandium-doped gadolinium iron garnet 2.60 Ce 0.36 Ca 0.04 sc 0.96 Fe 4.03 V 0.01 o 12 And preparation method thereof, concrete steps are as follows:

[0028] (1) Synthesis of polycrystalline raw materials: Weigh high-purity Gd according to the stoichiometric ratio 2 o 3 , Fe 2 o 3 Drugs, after being ground and mixed evenly, pressed into tablets, pre-sintered at 800°C for 10 hours, then sintered at 1300°C for 10 hours, after taking out, ground and pressed tablets, and then sintered at 1300°C for 10 hours to obtain Gd 3 Fe 5 o 12 polycrystalline material. The stoichiometric ratio of CeO 2 , NH 4 VO 3 The powder was mixed evenly, pressed into tablets, and then heated and sintered. During sintering, the temperature was kept at 200°C, 400°C, 670°C and 800°C for 2 hours respectively to obtain CeVO 4 polycrystalline powder. The stoichiometric CaCO 3 , Fe 2 o 3 The powder is pre-sintered at 900°C for 10h...

Embodiment 2

[0033] Magneto-optic crystal Gd with high cerium content and scandium-doped gadolinium iron garnet 2.61 Ce 0.33 Ca 0.06 sc 0.87 Fe 4.12 V 0.01 o 12 And preparation method thereof, concrete steps are as follows:

[0034] (1) Synthesis of polycrystalline raw materials: Weigh high-purity Gd according to the stoichiometric ratio 2 o 3 , Fe 2 o 3 Drugs, after being ground and mixed evenly, pressed into tablets, pre-sintered at 800°C for 10 hours, then sintered at 1300°C for 10 hours, after taking out, ground and pressed tablets, and then sintered at 1300°C for 10 hours to obtain Gd 3 Fe 5 o 12 polycrystalline material. The stoichiometric ratio of CeO 2 , NH 4 VO 3 The powder was mixed evenly, pressed into tablets, and then heated and sintered. During sintering, the temperature was kept at 200°C, 400°C, 670°C and 800°C for 2 hours respectively to obtain CeVO 4 polycrystalline powder. The stoichiometric CaCO 3 , Fe 2 o 3The powder is pre-sintered at 900°C for 10h ...

Embodiment 3

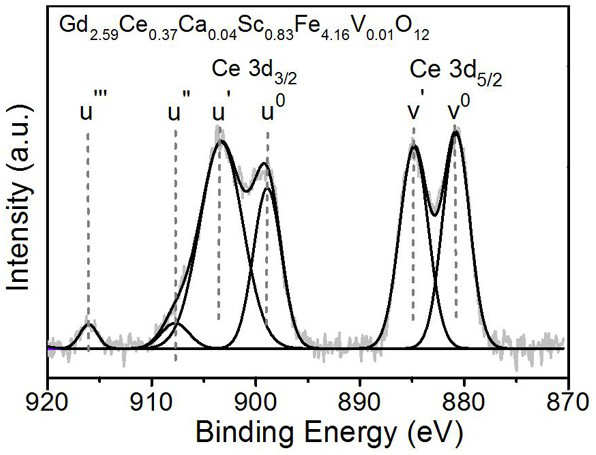

[0039] Magneto-optic crystal Gd with high cerium content and scandium-doped gadolinium iron garnet 2.59 Ce 0.37 Ca 0.04 sc 0.83 Fe 4.16 V 0.01 o 12 And preparation method thereof, concrete steps are as follows:

[0040] (1) Synthesis of polycrystalline raw materials: Weigh high-purity Gd according to the stoichiometric ratio 2 o 3 , Fe 2 o 3 Drugs, after being ground and mixed evenly, pressed into tablets, pre-sintered at 800°C for 10 hours, then sintered at 1300°C for 10 hours, after taking out, ground and pressed tablets, and then sintered at 1300°C for 10 hours to obtain Gd 3 Fe 5 o 12 polycrystalline material. The stoichiometric ratio of CeO 2 , NH 4 VO 3 The powder was mixed evenly, pressed into tablets, and then heated and sintered. During sintering, the temperature was kept at 200°C, 400°C, 670°C and 800°C for 2 hours respectively to obtain CeVO 4 polycrystalline powder. The stoichiometric CaCO 3 , Fe 2 o 3 The powder is pre-sintered at 900°C for 10h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com