Rare earth-doped NaGdF4 upconversion nanocrystalline and preparation method thereof

A rare earth doping, nanocrystalline technology, applied in nanotechnology, nano-optics, nanotechnology and other directions, can solve the problems of high reaction cost, unfavorable environmental protection, strong corrosion, etc., and achieve high phase purity, uniform size and high affinity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

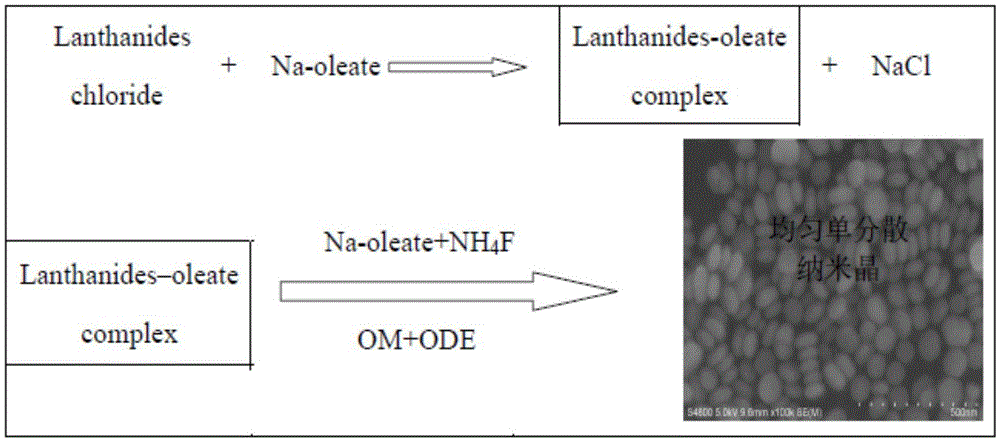

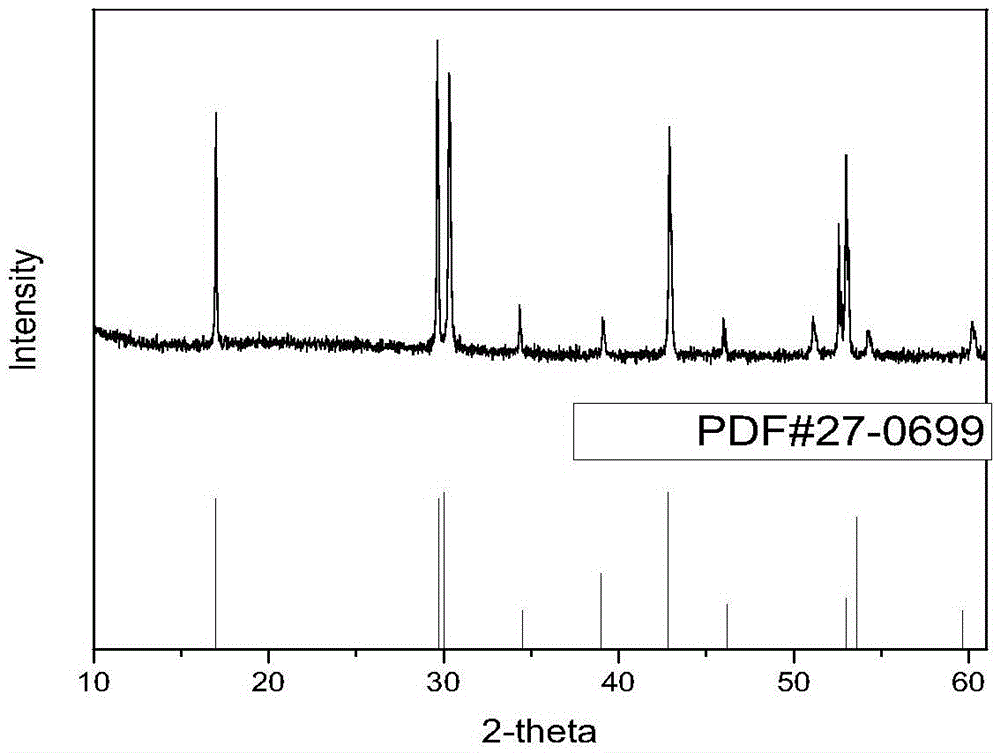

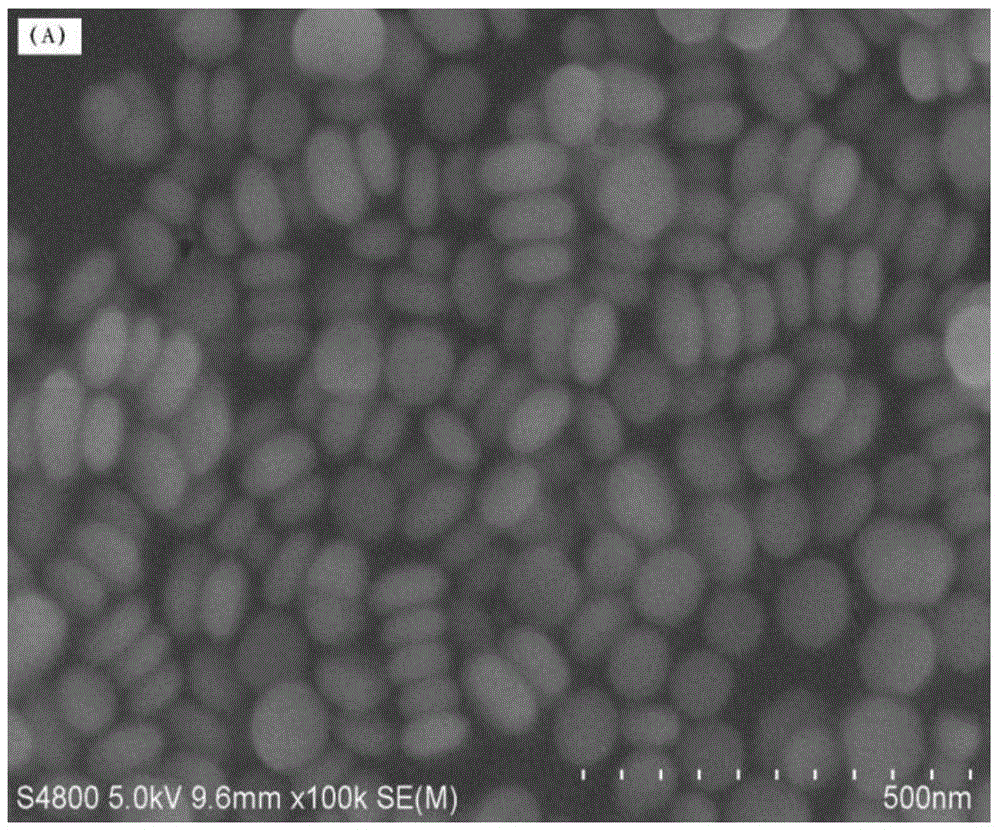

[0031] A Rare Earth Doped β-NaGdF 4 A preparation method for an up-conversion nanocrystalline material, comprising the steps of:

[0032] (1) According to the mass ratio of Gd:Yb:Er=78:20:2, the total amount of rare earth oxides (Ln 2 o 3 ) powder, put it into a container, add a small amount of deionized water, raise the temperature under magnetic stirring, set it at 100-135°C, when the temperature rises to 80°C, add 1.5mL hydrochloric acid dropwise, after a few minutes, the solid dissolves completely and becomes transparent solution; add 0.12g sodium hydroxide (NaOH) solid and 1mL oleic acid (OA) in another container, and heat up to 100-180°C under the condition of blowing Ar gas, until all the sodium hydroxide solid is dissolved to obtain an oily liquid;

[0033] (2) The transparent solution described in step (1) was evaporated to dryness at 150° C. under magnetic stirring in a fume hood to obtain a solid, which was mixed with the oily liquid described in step (1) and then...

Embodiment 2

[0039] A Rare Earth Doped β-NaGdF 4 A preparation method for an up-conversion nanocrystalline material, comprising the steps of:

[0040] (1) Gd:Yb:Er=81.5:18:0.5 weighs the total amount of rare earth oxide (Ln 2 o 3 ) powder, the follow-up steps are the same as (1) in Example 1, and the solid is completely dissolved to obtain a transparent solution, and the transparent solution is evaporated to dryness at 160°C under magnetic stirring in a fume hood to obtain a solid; in this container, add 0.12g sodium hydroxide (NaOH ) solid and 1mL oleic acid (OA), the temperature was raised to 140° C. under the condition of feeding Ar gas, until all the solids were dissolved to obtain an oily liquid;

[0041] (2) Add 6ml of ethanol, 3.5ml of hexane, and 4ml of deionized aqueous solution to the oily liquid described in step (1), then leave to stand for stratification, get the upper layer liquid, wash three times with deionized water, discard the lotion, After washing, it was heated to 6...

Embodiment 3

[0045] A Rare Earth Doped β-NaGdF 4 A preparation method for an up-conversion nanocrystalline material, comprising the steps of:

[0046] (1) According to the mass ratio of Gd:Yb:Tm=78:20:2, the total amount of rare earth oxides (Ln 2 o 3 ) powder, subsequent steps are with step (1) in example 1;

[0047] (2) The transparent solution described in step (1) was evaporated to dryness at 150° C. under magnetic stirring in a fume hood to obtain a solid, which was mixed with the oily liquid described in step (1) and then added to 6ml of ethanol and 3.5ml of hexane , 4ml of deionized water solution, magnetically stirred at room temperature for 4 hours, the liquid was poured into a separatory funnel, separated, the upper liquid was washed three times with deionized water, discarded the lotion, stirred and heated to 80°C after washing, and a waxy solid was obtained , add a mixed solution of 8mL oleylamine and 8mL octadecene, heat up to 160°C while stirring under the protective gas A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com