Zinc alloy endoscopic stapler cartridge and preparation method thereof

A zinc alloy and staple technology, applied in the field of medical devices, can solve the problems of not using degradable materials, improving corrosion resistance measures, accelerating the degradation of magnesium alloys, etc., to solve the problem of excessive degradation rate, improve binding force, and inhibit inflammation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

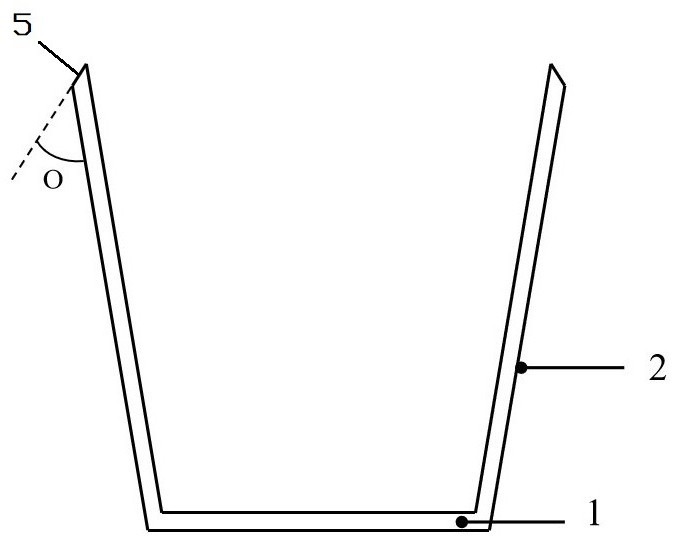

[0043] The preparation method of the above-mentioned zinc alloy staple is as follows:

[0044] 1) Select a zinc alloy ingot with a composition of 0.2wt% copper and 0.15wt% magnesium, and perform hot extrusion at 260°C with an extrusion ratio of 20:1 to obtain a zinc alloy bar;

[0045] 2) The zinc alloy rod obtained in step 1) is subjected to multi-pass continuous drawing deformation to obtain a zinc alloy wire with a diameter of 0.2 mm;

[0046] 3) Sand blast the surface of the zinc alloy wire obtained in step 2) at room temperature, select 5000-mesh gravel, and process it for 30 seconds to increase the roughness;

[0047] 4) heat-treat the zinc alloy wire obtained in step 3) at 250°C for 8 minutes, wash, dry, and sterilize;

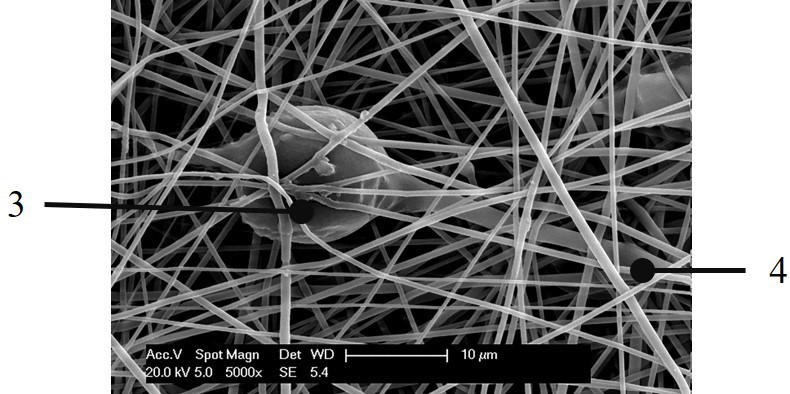

[0048]5) Electrospin the zinc alloy wire obtained in step 4). The electrospinning solution is a polylactic acid solution containing 5wt% magnesium powder, so that the outer layer of the wire is covered with an electrospinning film. The electrospinning ...

Embodiment 2

[0052] The preparation method of the above-mentioned zinc alloy staple is as follows:

[0053] 1) Select a zinc alloy ingot with a composition of 0.5wt% copper and 0.1wt% magnesium, and perform hot extrusion at 320°C with an extrusion ratio of 20:1 to obtain a zinc alloy rod;

[0054] 2) The zinc alloy rod obtained in step 1) is subjected to multi-pass continuous drawing deformation to obtain a zinc alloy wire with a diameter of 0.4 mm;

[0055] 3) Sand blast the surface of the zinc alloy wire obtained in step 2) at room temperature, select 3000-mesh gravel, and process it for 30 seconds to increase the roughness;

[0056] 4) heat-treat the zinc alloy wire obtained in step 3) at 300°C for 5 minutes, wash, dry, and sterilize;

[0057] 5) The zinc alloy wire obtained in step 4) is subjected to electrospinning treatment. The electrospinning solution is a polycaprolactone solution containing 20wt% magnesium powder, so that the outer layer of the wire is covered with an electrospi...

Embodiment 3

[0061] The preparation method of the above-mentioned zinc alloy staple is as follows:

[0062] 1) Select a zinc alloy ingot with a composition of 0.3wt% copper and 0.1wt% magnesium, and perform hot extrusion at 300°C with an extrusion ratio of 20:1 to obtain a zinc alloy rod;

[0063] 2) The zinc alloy rod obtained in step 1) is subjected to multi-pass continuous drawing deformation to obtain a zinc alloy wire with a diameter of 0.3mm;

[0064] 3) Sand blast the surface of the zinc alloy wire obtained in step 2) at room temperature, select 4000 mesh gravel, and process for 30 seconds to increase the roughness;

[0065] 4) heat-treat the zinc alloy wire obtained in step 3) at 280°C for 6 minutes, wash, dry, and sterilize;

[0066] 5) Electrospinning the zinc alloy wire obtained in step 4), the electrospinning solution is a mixed solution of polycaprolactone and polylactic acid containing 15wt% magnesium powder, so that the outer layer of the wire is covered with an electrospin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com