Composite, polylactic acid composite material, preparation method and application

A composite material and composite technology, applied in the field of composites and their preparation, can solve the problems of poor improvement effect of the toughness of biodegradable materials and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

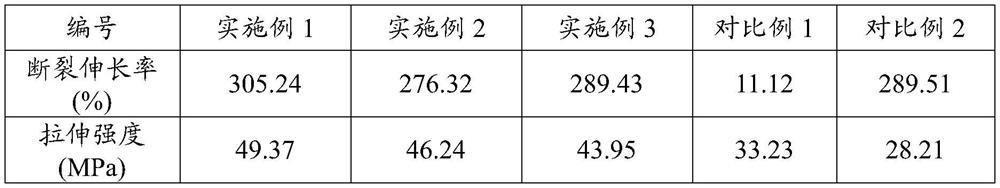

Examples

preparation example Construction

[0027]

[0028] The preparation method of the compound of the present invention comprises the following steps: (1) the step of preparing the surface-activated rare earth oxide; (2) the step of preparing the degradable polyester; (3) the step of preparing the compound. Details are given below.

[0029] Steps for preparing surface-activated rare earth oxides

[0030] The rare earth oxide is reacted with a coupling agent to obtain a surface activated rare earth oxide.

[0031] The rare earth oxide of the present invention can be lanthanum oxide, cerium oxide, praseodymium oxide, neodymium oxide, promethium oxide, samarium oxide, europium oxide, gadolinium oxide, terbium oxide, dysprosium oxide, holmium oxide, erbium oxide, thulium oxide, ytterbium oxide, One or more of lutetium oxide and yttrium oxide; preferably one or more of lanthanum oxide, cerium oxide, and samarium oxide; more preferably one of lanthanum oxide or cerium oxide. This can improve the strengthening and tou...

Embodiment 1

[0076] (1) The silane coupling agent KH550 is prepared into a coupling agent aqueous solution with a concentration of 10wt%, and the pH of the coupling agent aqueous solution is adjusted to 5 with acetic acid, and then the coupling agent aqueous solution is added to lanthanum oxide (rare earth oxide) in the form of a spray. In the material), the amount of coupling agent is controlled to be 1wt% of the mass of lanthanum oxide (rare earth oxide); use a high-speed mixer to mix lanthanum oxide (rare earth oxide) and coupling agent aqueous solution, and place it at 25°C for 0.5h, Then react in an oven at 55° C. for 4 hours; dry the reaction product at 100° C. to obtain a surface-activated rare earth oxide.

[0077](2) Form a mixture of succinic acid, sebacic acid, itaconic acid, butylene glycol, tetrabutyl titanate, and p-hydroxyanisole; wherein, the molar ratio of dibasic alcohol to dibasic acid is 1.05:1 , the consumption of catalyst is 0.5wt% of the total amount of dibasic acid ...

Embodiment 2

[0081] All the other are with embodiment 1 except following conditions:

[0082] The rare earth oxide is cerium oxide. The properties of the obtained polylactic acid composite materials are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Proportion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com