Grinding, punching and sampling tool for obtaining cylindrical specimen and using method of grinding, punching and sampling tool

A cylindrical and cylindrical tool technology, which is applied in the sampling device, grinding drive device, grinding machine parts, etc., can solve the problems of thick sampling thickness, large sampling size of core drill, and scrapping of tools.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

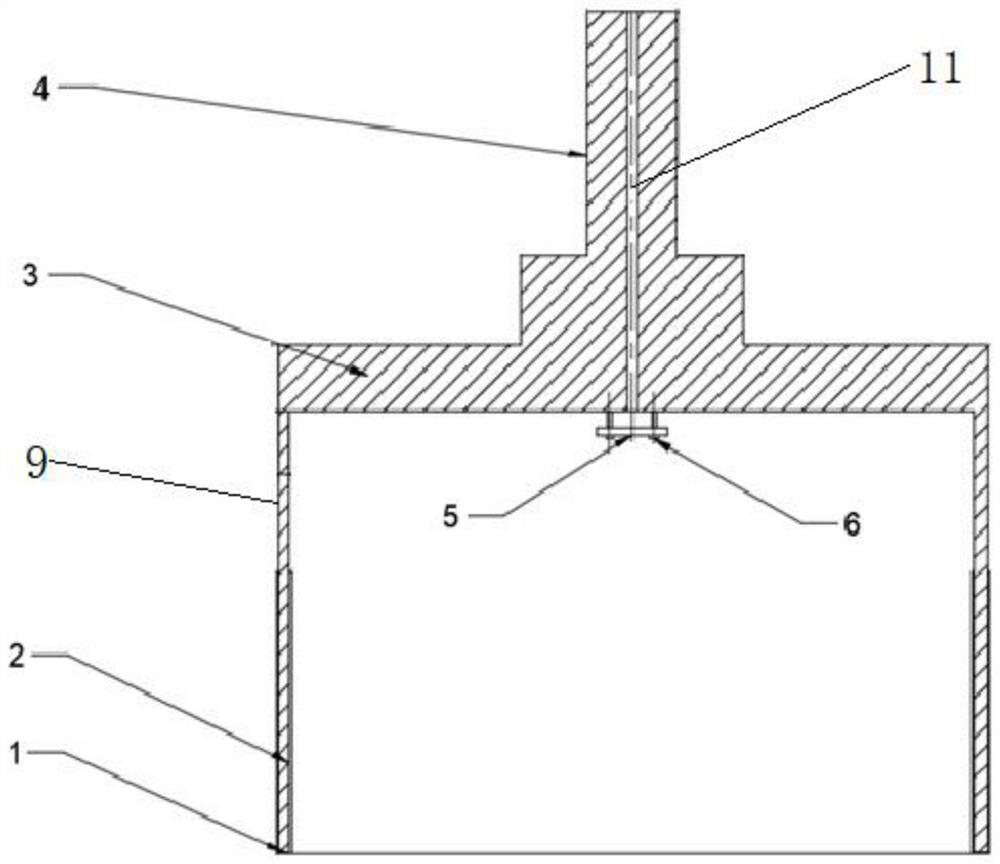

[0041] A punching, sampling and grinding tool with a structure such as figure 1 As shown, the cutting tool includes a blade 1 and a shank 4 integrally arranged at the bottom end of the blade body 3. The bottom end of the cylindrical blade 1 is fixedly connected with the shank 4 through the blade body 3, and the top end of the blade 1 is opened with a cylinder inward. The inner and outer walls of the cylindrical tool are cylindrical.

[0042] In the actual sampling operation (such as when sampling the outer surface of the pressure vessel), screw the tool holder 4 into the motor spindle of the fixed sampling machine, and the motor spindle provides the cutting power while the servo motor provides a continuous The downward low-speed micro-feed motion makes the cutting tool have both autorotation motion and downward feed motion, which can gradually cut a complete cylindrical material from the sampling object.

Embodiment 2

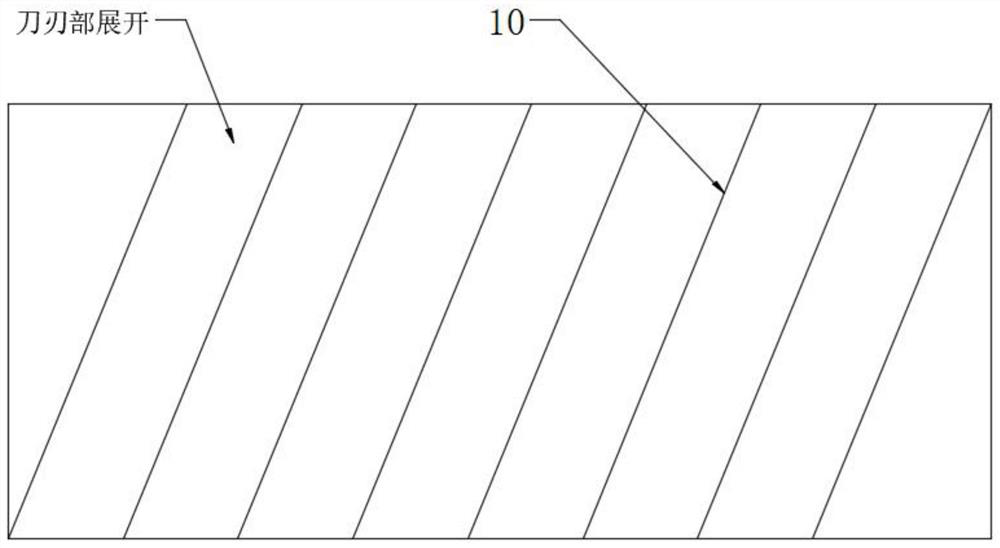

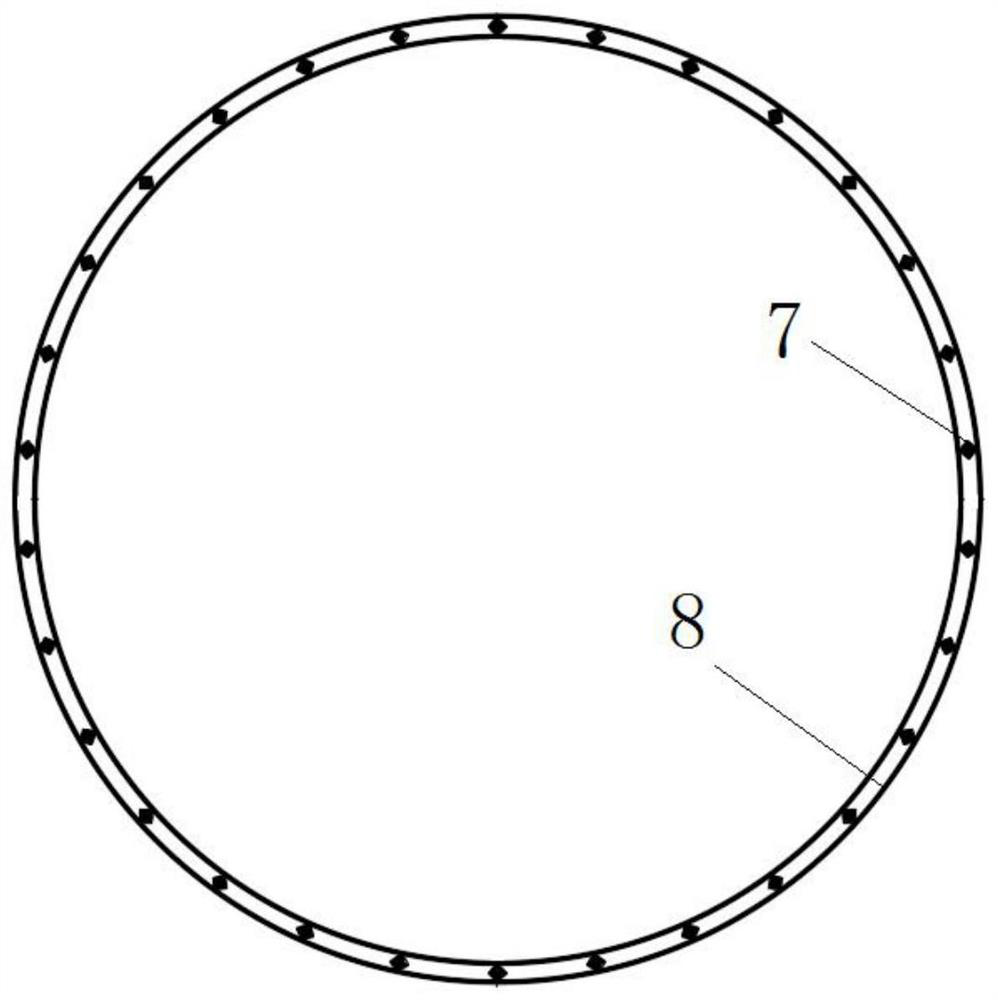

[0044] Using a cutting tool similar to that of Example 1, the difference is that the outer wall of the straight cylindrical tool of this embodiment is cylindrical, and the bottom end surface of the cutting edge part 1 of the straight cylindrical tool is inlaid with synthetic diamond 7, and the key cutting part is covered Emery coating 2. The diameter of the diamond particles is 0.2mm to 2mm, and the bottom end is inlaid with a synthetic diamond 7 every 5mm to 25mm. The area covered by emery is extending from the cutting edge to the bottom of the tool, and the extension length covered by emery is 10 to 80 mm. The particle size of the covered emery is any value between 30 mesh and 250 mesh.

[0045] A preferred embodiment is that during the sampling process, cooling liquid is added to make grinding smooth and protect the tool. A cooling fluid channel is arranged in the center of the knife handle, and a shielding baffle is connected to the end of the channel, and the shielding baf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Extension length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com