Large cladding nickel base surfacing process of barrel

A cylinder, nickel-based technology, used in manufacturing tools, welding equipment, welding accessories, etc., can solve the problems of high dilution rate of welding wire submerged arc welding, high labor intensity of welders, and difficult to guarantee the quality of joint surface and composition requirements. , to reduce the labor intensity of surfacing welding, improve the efficiency of surfacing welding and cladding, and shorten the product manufacturing cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

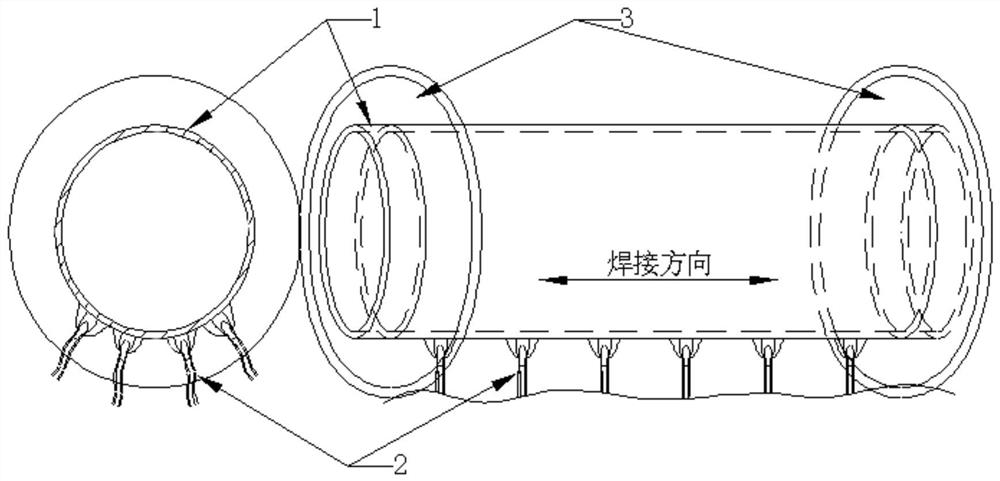

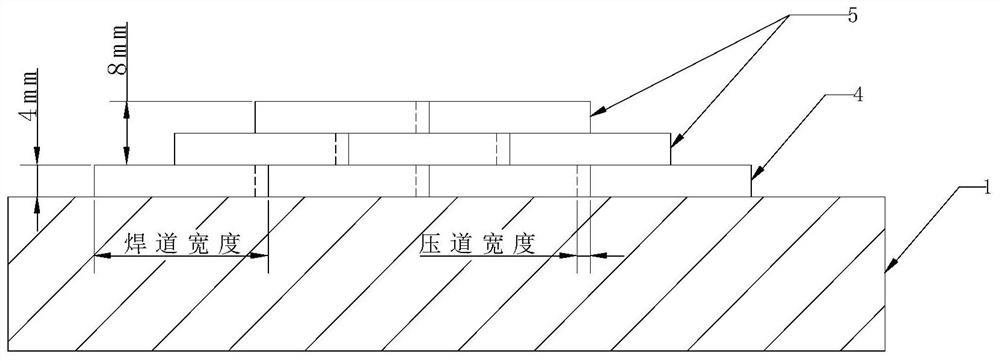

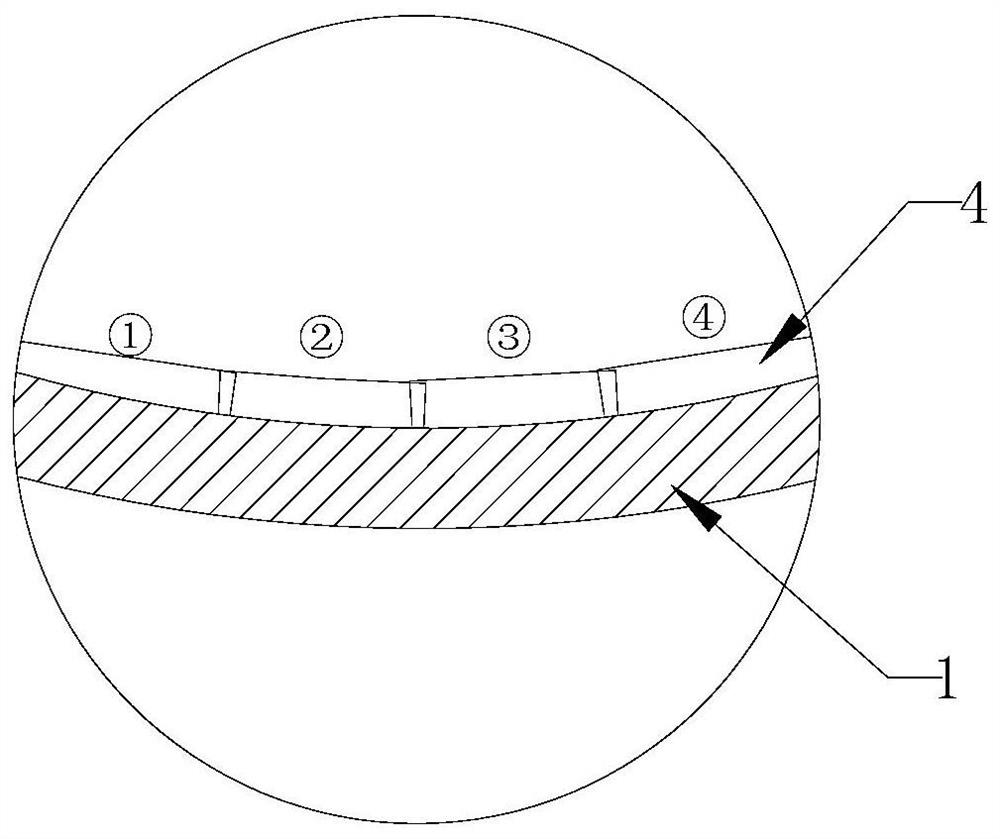

[0026] A large cladding nickel-based surfacing process for a cylinder body, mainly comprising a cylinder body 1, a flame preheating tool 2, an outer tool hoop 3, a transition layer 4, and a corrosion-resistant layer 5. It specifically includes the following steps and key technologies:

[0027] (1) At the two ends of the two ends of the cylinder body 1, the length from the two ends of the cylinder body is 100-300mm, and an outer tooling hoop is respectively welded, the material is Q345R or other low alloy steel, and the thickness is 30-70mm;

[0028] (2) Clean the inner surface of cylinder body 1 by grinding, polishing, brushing, and cleaning to remove rust, oil stains, dust and other harmful impurities that affect the quality of surfacing welding on the inner surface of cylinder body 1. / T47013-2015 requires 100% magnetic particle (MT) testing. After passing the test, place the cylinder 1 horizontally on the roller frame, adjust the orientation of the surfacing welding head an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com