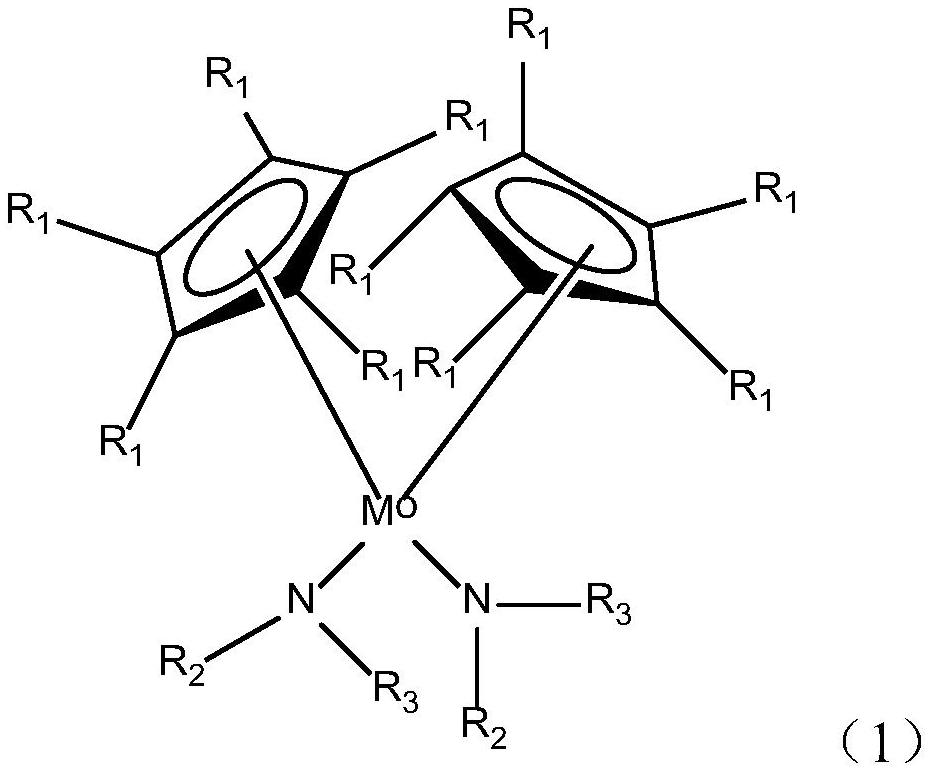

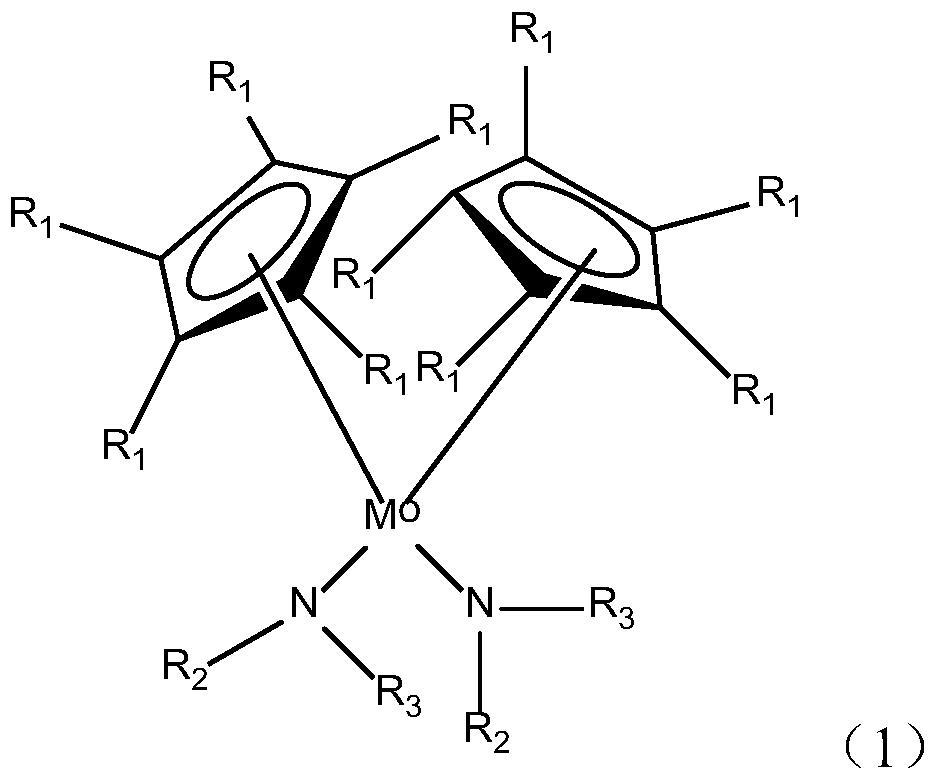

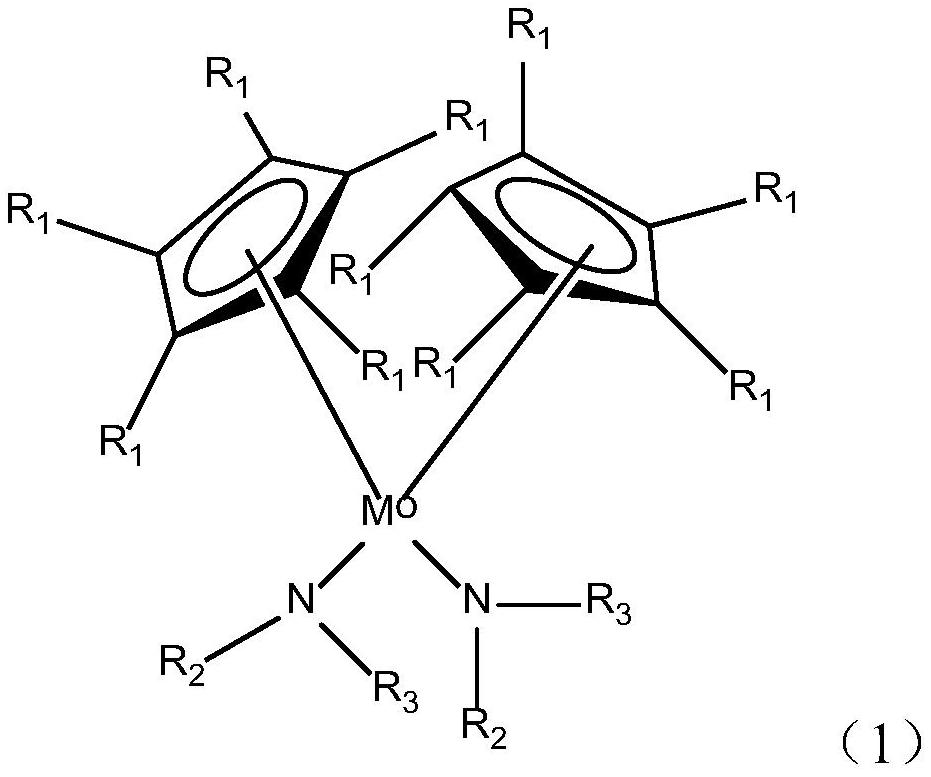

Diamino molybdenum dicyclopentadienyl complex as well as preparation method and application thereof

A diamine molybdenum molybdenum and complex technology, applied in chemical instruments and methods, metallocene, gaseous chemical plating, etc., can solve the problems of limiting the application of MoS2, many uncontrollable parameters, and high deposition temperature, and achieve important scientific research. Value, broad industrial prospects, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The invention provides a preparation method of diamine molybdenocene complexes. The dichloromolybdenocene complexes are synthesized in one step by mixing in one pot, and then the dichloromolybdenocene complexes are mixed with dioxane The reaction of diaminomolybdenum molybdenum complexes with lithium amide was prepared. The technical solution is as follows:

[0051] A kind of preparation method of diaminomolybdenum molybdenum compound, comprises the following steps:

[0052] dissolving molybdenum pentachloride in the first solvent, and cooling for the first time to prepare the first solution;

[0053] dissolving the substituted lithium cyclopentadiene and sodium borohydride in a second solvent, and cooling for the second time to prepare a second solution;

[0054] Mix the first solution and the second solution, mix the first solution and the second solution, stir for 2h-4h, heat up to 55°C-75°C, react for 20h-28h, add alkane to the reaction product for extraction, fil...

Embodiment 1

[0097] This example provides a diamine-based molybdenumocene complex and its preparation method, which is carried out in a reaction vessel protected by a high-purity argon atmosphere, and the specific steps are as follows:

[0098] Step 1: Under an argon atmosphere, add 50 grams (0.367 mol) of pentamethylcyclopentadiene and 50 milliliters of n-hexane to a 500 milliliter Schlenk bottle, lower the temperature of the system to 0 ° C, and dropwise add 147 milliliters of n-butyl Lithium in n-hexane solution, the concentration of n-butyllithium is 2.5 moles per liter. After the dropwise addition, return to room temperature and react for 2 hours, filter, wash with n-hexane, and dry to obtain 41 g of lithium pentamethylcyclopentadiene, with a yield of 80%;

[0099] Step 2: Add 10 grams (0.037 mol) of molybdenum pentachloride, 25 milliliters of toluene and 125 milliliters of tetrahydrofuran into a 250 milliliter Schlenk bottle in sequence, stir to dissolve and then cool to -10°C to obt...

Embodiment 2

[0103] This embodiment provides a diamino molybdenum molybdenum complex and a preparation method thereof, the specific steps are as follows:

[0104] Step 1: Under a nitrogen atmosphere, add 80 grams (0.179 mol) of pentaphenylcyclopentadiene and 100 milliliters of n-hexane to a 500 milliliter Schlenk bottle, lower the temperature of the system to 0 ° C, and add 72 milliliters of n-butyllithium dropwise n-hexane solution, the concentration of n-butyllithium is 2.5 moles per liter. After the dropwise addition, return to room temperature and react for 2 hours, filter, wash with n-hexane, and dry to obtain 70 g of lithium pentamethylcyclopentadiene, with a yield of 86%;

[0105] Step 2: Add 22 grams (0.081 mol) of molybdenum pentachloride, 60 milliliters of toluene and 250 milliliters of tetrahydrofuran to a 500 milliliter Schlenk bottle, stir and dissolve, then cool to -10°C to obtain the first solution. Add 38 g (0.084 mol) of pentaphenylcyclopentadienyl lithium prepared in ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com