Anti-corrosion composite layer, application and preparation method of anti-corrosion composite lining layer

A composite layer and preparation process technology, applied in the direction of coating, process efficiency improvement, metal material coating process, etc., can solve the problems of low physical penetration resistance, metal shell contact, corrosive leakage, etc., and achieve good corrosion resistance Penetration, Thickness Reduction, High Compatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

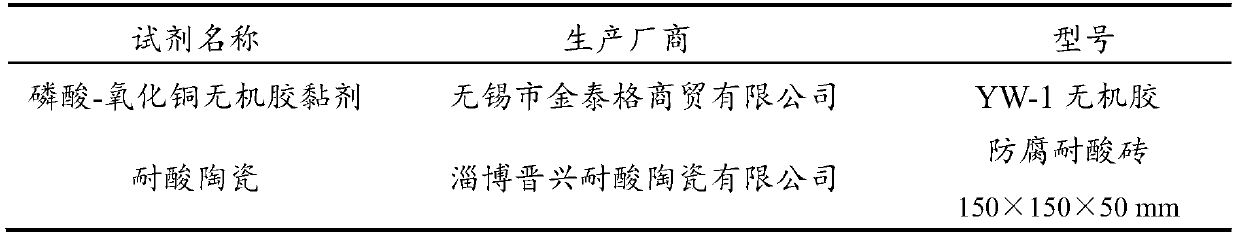

Embodiment 1

[0050] The amorphous alloy used in this embodiment consists of (Ni 58 Ta 34 sn 8 ) 97 Er 3 , selecting elemental metals with a purity of 99.99% for master alloy melting in a high-purity argon environment in which titanium ingots absorb oxygen in a vacuum non-consumable electric arc furnace, and the obtained master alloy is used to prepare amorphous alloy powder and amorphous flakes.

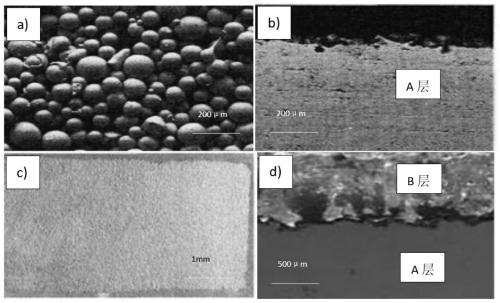

[0051] (1) Preparation of amorphous alloy powder

[0052] The master alloy is made into amorphous alloy powder by nitrogen atomization process, the atomization pressure is 10MPa, the atomization temperature is 1600K, the mass flow ratio is about 0.6, and it is further sieved into particles with a particle size of 25-30μm and a spherical microscopic shape. And ellipsoidal amorphous alloy powder.

[0053] (2) Preparation of amorphous flakes

[0054] Ultrasonic cleaning of the master alloy is put into a quartz tube with a small hole at the bottom, remelted on a vacuum strip machine using an in...

Embodiment 2

[0063] The amorphous alloy used in this embodiment consists of (Ni 55 Ta 35 sn 10 ) 96 Er 4 , smelting according to the method of Example 1 and preparing a master alloy.

[0064] (1) Preparation of amorphous alloy powder

[0065] The master alloy is made into amorphous alloy powder through the nitrogen atomization process, the atomization pressure is 8MPa, the atomization temperature is 1800K, the mass flow ratio is about 0.6, and it is further screened into a particle size of 30-40μm and a spherical microscopic shape. And ellipsoidal amorphous alloy powder.

[0066] (2) Preparation of amorphous flakes

[0067] Ultrasonic cleaning of the master alloy is put into a quartz tube with a small hole at the bottom, remelted on a vacuum strip machine using an induction heating device, and the molten alloy is blown to the surface of a high-speed rotating copper roller with high-pressure argon to obtain a width of 2 to 3mm. For a thin strip sample with a thickness of 30-45 μm, us...

Embodiment 3

[0075] The amorphous alloy used in this embodiment consists of (Ni 57 Ta 34 sn 9 ) 94 Er 6, smelting according to the method of Example 1 and preparing a master alloy.

[0076] (1) Preparation of amorphous alloy powder

[0077] The master alloy is made into amorphous alloy powder by nitrogen atomization process, the atomization pressure is 9MPa, the atomization temperature is 1700K, the mass flow ratio is about 0.6, and it is further sieved into particles with a particle size of 30-40μm and a spherical microscopic shape. And ellipsoidal amorphous alloy powder.

[0078] (2) Preparation of amorphous flakes

[0079] Ultrasonic cleaning of the master alloy is put into a quartz tube with a small hole at the bottom, remelted on a vacuum strip machine using an induction heating device, and the molten alloy is blown to the surface of a high-speed rotating copper roller with high-pressure argon to obtain a width of 2 to 3mm. For a thin strip sample with a thickness of 35-45 μm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com