Preparation method of high-purity nano aluminum oxide

A nano-alumina, high-purity technology, applied in the preparation of aluminum hydroxide, chemical instruments and methods, inorganic chemistry, etc., can solve the difficulties in the preparation of nano-alpha alumina, narrow and ultra-fine α-alumina, and lack of particle size distribution and other problems to achieve the effect of avoiding excessive grain growth, avoiding agglomeration, and narrowing the particle size distribution range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] This embodiment provides a kind of high-purity nano-alumina, and its preparation method specifically includes the following steps:

[0073] 1) Al(NO 3 ) 3 9H 2 O and tartaric acid are dissolved in deionized water to obtain solution A;

[0074] 2) Take polyvinyl alcohol and dissolve it in 10 times the weight of deionized water, heat and stir until the polyvinyl alcohol is completely dissolved and becomes a uniform sol B;

[0075] 3) Under stirring, slowly add the solution A of step 1) into the sol B dropwise, continue heating and stirring in a water bath for 60 minutes to obtain a mixed solution C;

[0076] 4) Add ammonia water to solution C under stirring to adjust pH=10.0 to obtain viscous wet gel D;

[0077] 5) Wet gel D was firstly incubated at 128°C for 45 minutes, and then at 155°C for 90 minutes to obtain dry gel, which was ground into powder;

[0078] 6) The dry gel powder obtained in step 5) is obtained by heat-preserving and calcining at 1125° C. for 5 hou...

experiment example 1

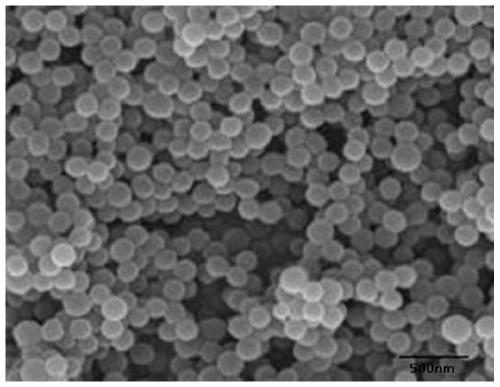

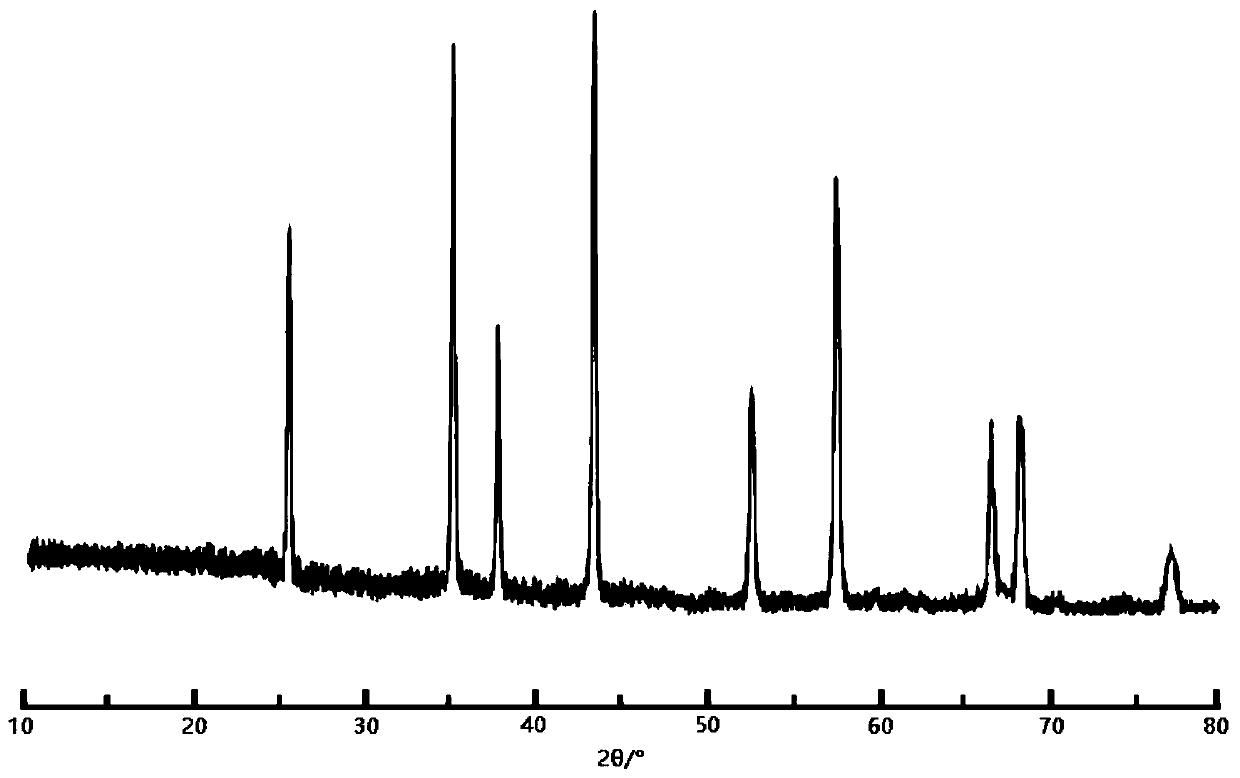

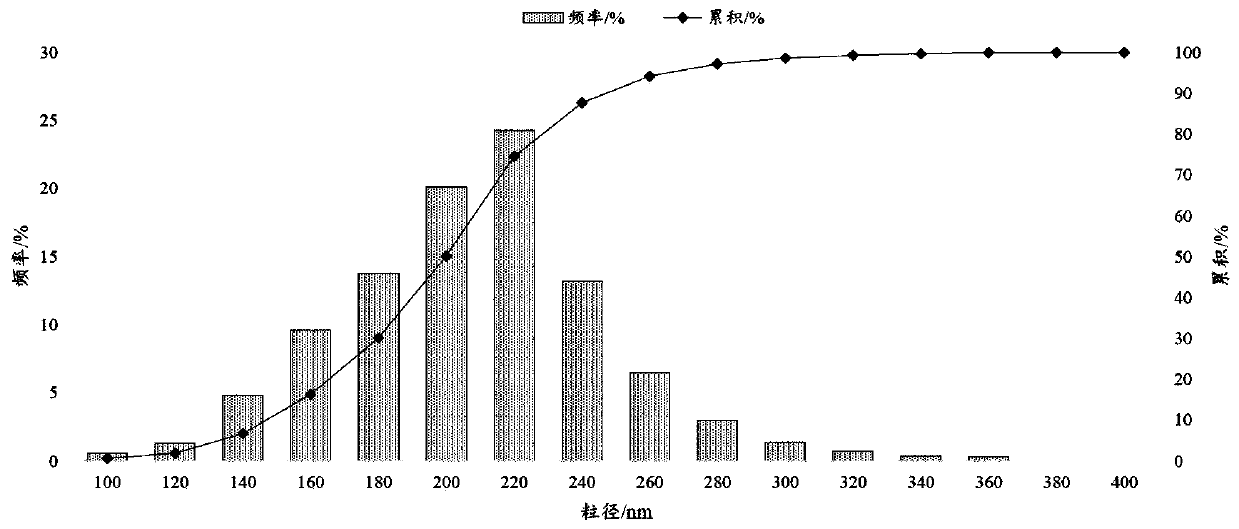

[0094] The morphological characteristics of the composite samples were observed with a Japanese Hitachi SU-1500 scanning electron microscope, and the observation voltage was 15kV; the powder X-ray diffraction test was carried out with a D / max-r A X-ray powder diffractometer of Rigaku Corporation, Cu target , the target voltage is 40kV, the target current is 30mA, Kα rays, the scanning speed is 7° / min, the scattering slit is 1°, and the receiving groove is 0.15nm. From its SEM image ( figure 1 ) It can be seen that the alumina particles are small spherical particles with a uniform particle size and an average particle size of D 50 Around 200nm. By its XRD image ( figure 2 ) shows that the position of each diffraction peak is related to that of α-Al 2 o 3 The XRD standard card (JCPDS NO.46-1212) is consistent, and the diffraction peaks are sharp and free of impurity peaks, indicating that the prepared α-Al 2 o 3 Higher purity and higher crystallinity. The final product h...

Embodiment 2

[0096] This embodiment provides another kind of nano-alumina, its preparation method and formula components are basically similar to the embodiment, the difference is that in this embodiment, glycine is used instead of tartaric acid and Al(NO 3 ) 3 9H 2 O was co-dissolved in deionized water to obtain solution A, and nano-alumina was prepared according to the same subsequent steps as in Example 1.

[0097] In addition, this embodiment also provides another heat insulating material, which is prepared through the following steps:

[0098] 1) The high-purity nano-alumina powder described in this embodiment, the opacifying agent silicon carbide, and the reinforcing fiber high-strength glass fiber are stirred and dispersed evenly according to the weight ratio of 20:14:1 to obtain a mixture;

[0099] 2) Mix the mixture described in step 1) at 330T / m 2 The pressure is pressed into aluminum oxide nano heat insulation board.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com