Al-Ti-B target material and powder solid phase alloying sintering method thereof

A technology of solid-phase alloying and sintering method, which is applied in metal material coating process, ion implantation plating, coating, etc., can solve the problems that the content is limited and cannot be used to prepare titanium and boron-aluminum-titanium-boron alloy targets, etc. , to achieve low production cost, avoid melting and flow, and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

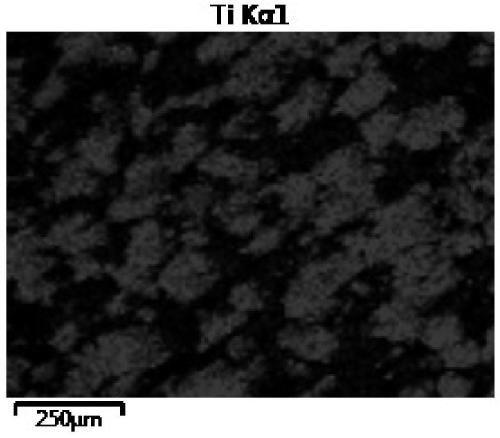

Image

Examples

Embodiment 1

[0033] The embodiment of the present invention provides a solid phase alloying and sintering method of aluminum titanium boron target powder, which includes the following steps:

[0034] Step 1: Choose the average particle size of the powder to be 10μm. Elemental aluminum powder, titanium powder and boron powder with a purity of more than 99.9%. The atomic percentage of aluminum powder and titanium powder is: Al:Ti=80%:20%. First, mix the aluminum and titanium powders together. Add boron powder according to 1% of the total amount of aluminum and titanium mixed powder atoms; weigh the aluminum powder, titanium powder and boron powder in the above proportions, put them in the mixing tank, and mix on the three-dimensional mixer for 30 minutes ;

[0035] Step 2: Put the mixed materials in step 1 into a planetary high-energy ball mill for ball milling. The ball-to-material ratio is 10:1, and the milling time is 1h. The ball mill tank can be filled with a protective atmosphere such as a...

Embodiment 2

[0041] The embodiment of the present invention provides a solid phase alloying and sintering method of aluminum titanium boron target powder, which includes the following steps:

[0042] Step 1: Choose the average particle size of the powder to be 50μm. Elemental aluminum powder, titanium powder and boron powder with a purity of more than 99.9%. The atomic percentage of aluminum powder and titanium powder is: Al:Ti=20%:80%. First, mix the aluminum and titanium powders together. Add boron powder according to 20% of the total atom amount of the aluminum-titanium mixed powder; weigh the aluminum powder, titanium powder and boron powder in the above proportions, put them into the mixing tank, and mix on the three-dimensional mixer for 60 minutes ;

[0043] Step 2: Put the mixed materials in step 1 into a planetary high-energy ball mill for ball milling. The ball-to-material ratio is 10:1 and the milling time is 12h. The ball mill tank can be filled with a protective atmosphere such as...

Embodiment 3

[0049] The embodiment of the present invention provides a solid phase alloying and sintering method of aluminum titanium boron target powder, which includes the following steps:

[0050] Step 1: Choose the average particle size of the powder to be 20μm. Elemental aluminum powder, titanium powder and boron powder with a purity of more than 99.9%. The atomic percentage of aluminum powder and titanium powder is: Al:Ti=70%:30%. First, mix the aluminum and titanium powders together. Add boron powder according to 10% of the total atomic amount of the aluminum-titanium mixed powder; weigh the aluminum powder, titanium powder and boron powder in the above proportions, put them in the mixing tank, and mix on the three-dimensional mixer for 40 minutes ;

[0051] Step 2: Put the mixed materials in step 1 into a planetary high-energy ball mill for ball milling. The ball-to-material ratio is 10:1, and the milling time is 6 hours. The ball mill tank can be filled with a protective atmosphere su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com