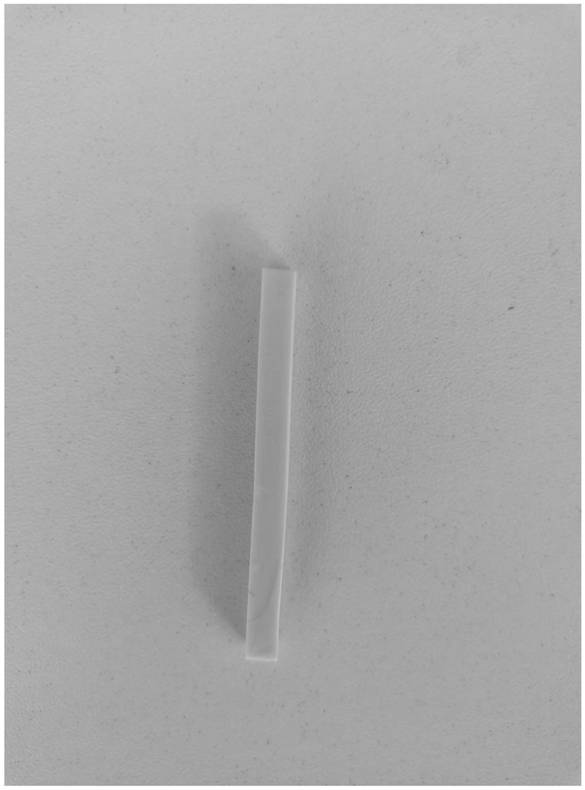

Jade-like glass-ceramic and preparation method thereof

A glass-ceramic and jade technology, which is used in glass manufacturing equipment, glass furnace equipment, manufacturing tools, etc., can solve the problems of unsatisfactory decorative effect, poor high temperature resistance and ultraviolet resistance, easy to break, etc., to improve the aesthetics. And decorative meaning, colorful and colorful, solid internal structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The present invention also provides the preparation method of described jade-like glass-ceramics, comprising the steps of:

[0053] Weigh each raw material according to the components, pulverize, and heat and melt to obtain molten glass;

[0054] Shaping, annealing and cooling the molten glass to form glass;

[0055] The shaped glass is subjected to nucleation and crystallization.

[0056] In one specific embodiment, the annealing process parameters are: annealing at 700-750° C. and holding for 1-4 hours. Under the conditions of the annealing process parameters, it can be guaranteed that the material will not generate internal micro-cracks and then cracks due to the temperature difference during the annealing process, thereby ensuring the uniformity of the overall strength of the glass.

[0057] In one of the specific embodiments, the nucleation process parameters are: nucleation at 800-860° C., heat preservation for 1-10 hours. Under the conditions of the nucleation...

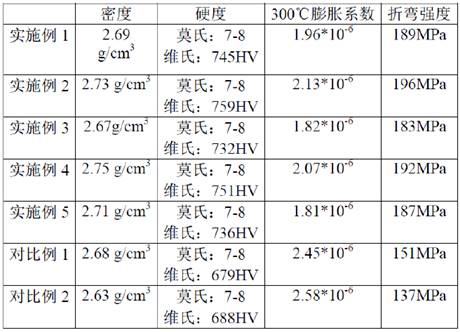

Embodiment 1

[0066] The present embodiment is a jade-like glass-ceramic, the raw materials and preparation method of which are as follows:

[0067] (1) Weighing of raw materials: Accurately weigh the following components (based on the total weight of the components as 100g): 53.8g of silicon dioxide, 17.7g of aluminum oxide, 7.5g of magnesium oxide, 1.85g of calcium oxide (calculated as calcium carbonate The amount of calcium carbonate is 3.3 g), titanium dioxide 5 g, zirconia 3 g, phosphorus pentoxide 5.15 g (8.34 g in the form of ammonium dihydrogen phosphate), barium oxide 2 g (in the form of barium carbonate 2.57 g), sodium antimonate 1.6 g, ferrous oxide 2.4 g.

[0068] (2) Crushing: After weighing, pour the raw materials into a mortar (agate material), grind them thoroughly, and pass through a 100-mesh sieve.

[0069] (3) Heating and melting: put the mixed batch in a programmable electric furnace to raise the temperature to 1000°C at 10°C / min, keep it warm for 1.5h, then raise the t...

Embodiment 2

[0075] The present embodiment is a jade-like glass-ceramic, the raw materials and preparation method of which are as follows:

[0076] (1) Weighing of raw materials: Accurately weigh the following raw material components (based on the total weight of raw materials as 100g): 51.1g of silicon dioxide, 18.9g of aluminum oxide, 11.1g of magnesium oxide, 1.77g of calcium oxide (calculated as calcium carbonate form 3.16g), titanium dioxide 4g, zirconia 4.2g, phosphorus pentoxide 1.63g (add 2.64g in the form of ammonium dihydrogen phosphate), barium oxide 2g (add 2.57g in the form of barium carbonate), sodium antimonate 1.6 g, calcium fluoride 0.8g, cobalt oxide 1.4g, nickel oxide 1.5g.

[0077] (2) Crushing: After weighing, pour the raw materials into a mortar (agate material), grind them thoroughly, and pass through a 100-mesh sieve.

[0078] (3) Heating and melting: put the mixed batch in a programmable electric furnace to raise the temperature to 1000°C at 10°C / min, keep it warm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com