Preparation method of molybdenum disulfide (MoS2) based nanocomposite film doped with Ti and C

A nano-composite, molybdenum disulfide technology, applied in ion implantation plating, metal material coating technology, coating and other directions, can solve problems such as wear failure, improve wear resistance life, improve strength and wear resistance, improve adaptive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

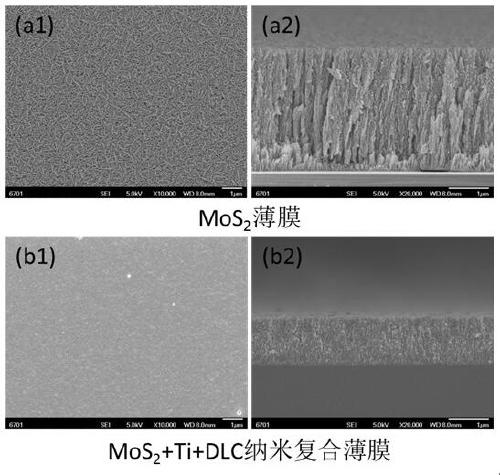

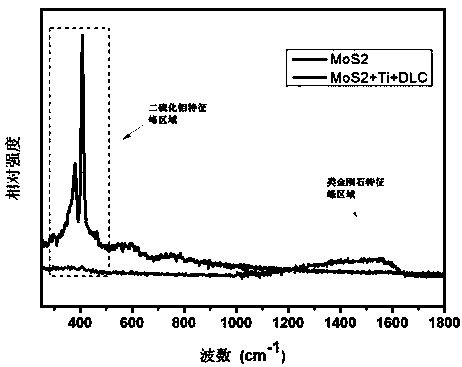

Image

Examples

Embodiment 1

[0034] (1) Install pure molybdenum disulfide targets, high-purity metal Ti targets and graphite targets as sputtering materials at the three target positions of the multi-target magnetron sputtering system;

[0035] (2) Place the monocrystalline silicon wafer in absolute ethanol and analytically pure petroleum ether for ultrasonic cleaning, 10 minutes each time. After drying, place it on the sample stage in the vacuum chamber; the sample stage keeps rotating during the deposition process, and the rotation rate is 6~9 rpm;

[0036] (3) Use the mechanical pump of the magnetron sputtering system and the secondary exhaust system of the molecular pump to pump the vacuum of the vacuum chamber to 1.0×10 -3 Pa; Introduce high-purity argon gas and adjust the air pressure to 6.0 Pa, introduce -550 V pulse bias voltage on the sample stage, and perform plasma cleaning for 10 minutes;

[0037] (4) Adjust the vacuum chamber pressure to 0.55 Pa, and use a DC power supply (current 5.0A) to ...

Embodiment 2

[0042] (1) Install pure molybdenum disulfide targets, high-purity metal Ti targets and graphite targets as sputtering materials at the three target positions of the multi-target magnetron sputtering system;

[0043] (2) Place GCr15 bearing steel with surface roughness ≤ 1.6 μm in absolute ethanol and analytical pure petroleum ether for ultrasonic cleaning, each time for 15 minutes. After drying, place it on the sample stage in the vacuum chamber; the sample stage keeps rotating during the deposition process, and the rotation rate is 6 revolutions per minute;

[0044] (3) Use the mechanical pump of the magnetron sputtering system and the secondary exhaust system of the molecular pump to pump the vacuum of the vacuum chamber to 1.0×10 -3 Pa; Introduce high-purity argon gas and adjust the air pressure to 5.0 Pa, introduce -550 V pulse bias voltage on the sample stage, and perform plasma cleaning, and the cleaning time is 30 minutes;

[0045] (4) Adjust the pressure of the vacuu...

Embodiment 3

[0050] (1) Install pure molybdenum disulfide targets, high-purity metal Ti targets and graphite targets as sputtering materials at the three target positions of the multi-target magnetron sputtering system;

[0051] (2) Place the thrust bearing in absolute ethanol and analytically pure petroleum ether for ultrasonic cleaning, 15 minutes each time. After drying, place it on the sample stage in the vacuum chamber; the sample stage keeps rotating during the deposition process, and the rotation rate is 9 revolutions per minute;

[0052] (3) Use the mechanical pump of the magnetron sputtering system and the secondary exhaust system of the molecular pump to pump the vacuum of the vacuum chamber to 1.0×10 -3 Pa; Introduce high-purity argon gas and adjust the air pressure to 6.0 Pa, introduce -550 V pulse bias voltage on the sample stage, and perform plasma cleaning, and the cleaning time is 30 minutes;

[0053] (4) Adjust the pressure of the vacuum chamber to 0.5 Pa, and use a DC p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com