Vitrified dilatant polymer foam hybrid material

A polymer and dilatant technology, applied in the field of intelligent materials, can solve problems such as single structure and performance, and achieve excellent comprehensive performance, large foaming ratio, and strong compressibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[2131] In the preparation process of polymer foam particles, other optional additives are preferably antioxidants, light stabilizers, heat stabilizers, crosslinking agents, chain extenders, compatibilizers, phase change additives, tougheners, plasticizers, flame retardants.

[2132] In the present invention, the optional fillers in the polymer mainly play the following roles: ①Reduce the shrinkage rate of the molded product, improve the dimensional stability, surface finish, smoothness and flatness or dullness of the product ②Adjust the viscosity of the polymer; ③Meet different performance requirements, such as improving the impact strength and compressive strength, hardness, stiffness and modulus of polymer materials, improving wear resistance, increasing heat distortion temperature, improving electrical conductivity and thermal conductivity Etc.; ④ Improve the coloring effect of the pigment; ⑤ Give light stability and chemical corrosion resistance;

[2133] The optional fil...

Embodiment 1

[2178]

[2179] Weigh 3g terephthalaldehyde and dissolve it in 50ml absolute ethanol, add 8.9g diethyl malonate, 0.2g piperidine, 0.2g acetic acid, reflux reaction for 12h under argon atmosphere, then cool down and purify to obtain compound (a ). Weigh 150ml of tetrahydrofuran solvent in a reaction flask, add 4.0g of compound (a) and 3.2g of triethylenetetramine, stir well, cool to room temperature and let stand for 6h, then heat to 50°C for 10h to prepare polymer 1.

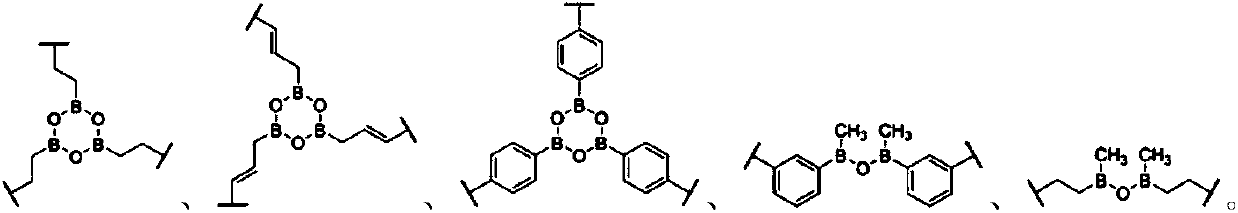

[2180] With the polyethylene of 80 parts by weight, the polymer 1 of 20 parts by weight, the blowing agent AC of 3 parts by weight, the talcum powder of 3 parts by weight, the double nitrogen heterocycle crosslinking agent (b) of 0.5 parts by weight, 0.8 parts by weight Zinc oxide, the zinc stearate of 1 weight part, the polyethylene wax of 3 weight parts, the antioxidant 1010 of 0.05 weight part are mixed homogeneously, then above-mentioned mixture is added to screw extruder granulation and obtain polymer fo...

Embodiment 2

[2183]

[2184] Using compound (a), compound (b) and styrene as raw materials, cumyl dithiobenzoate as chain transfer agent, RAFT copolymerization at 110°C to prepare polystyrene containing borane and phosphine side groups . Using AIBN as an initiator, styrene-pyridine copolymer was prepared by radical copolymerization of styrene and 4-vinylpyridine.

[2185] Add a certain amount of toluene solvent into a dry and clean reaction flask, pass argon gas to remove water and oxygen for 1 hour, then add 8 mmol of styrene-pyridine copolymer and 0.01 mol of phenyl selenium bromide (c), stir and mix for 1 hour to form the first A network, then add 5 mmol of polystyrene containing borane and phosphane side groups, 0.02 mol of diethyl azodicarboxylate, continue the reaction for 2 hours, and then place the mixed solution in a suitable mold and dry it in a vacuum oven at 80 °C After 24 hours, a polystyrene-based polymer was finally obtained. With the polystyrene-based polymer of 90 wei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com