Device and method for preparing coated powder

A technology for coating powder and powder particles, which is applied in the field of preparation of composite powder materials and can solve the problems of difficulty in powder feeding, reduction of coating performance of coating powder preparation, and low efficiency of coating powder, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

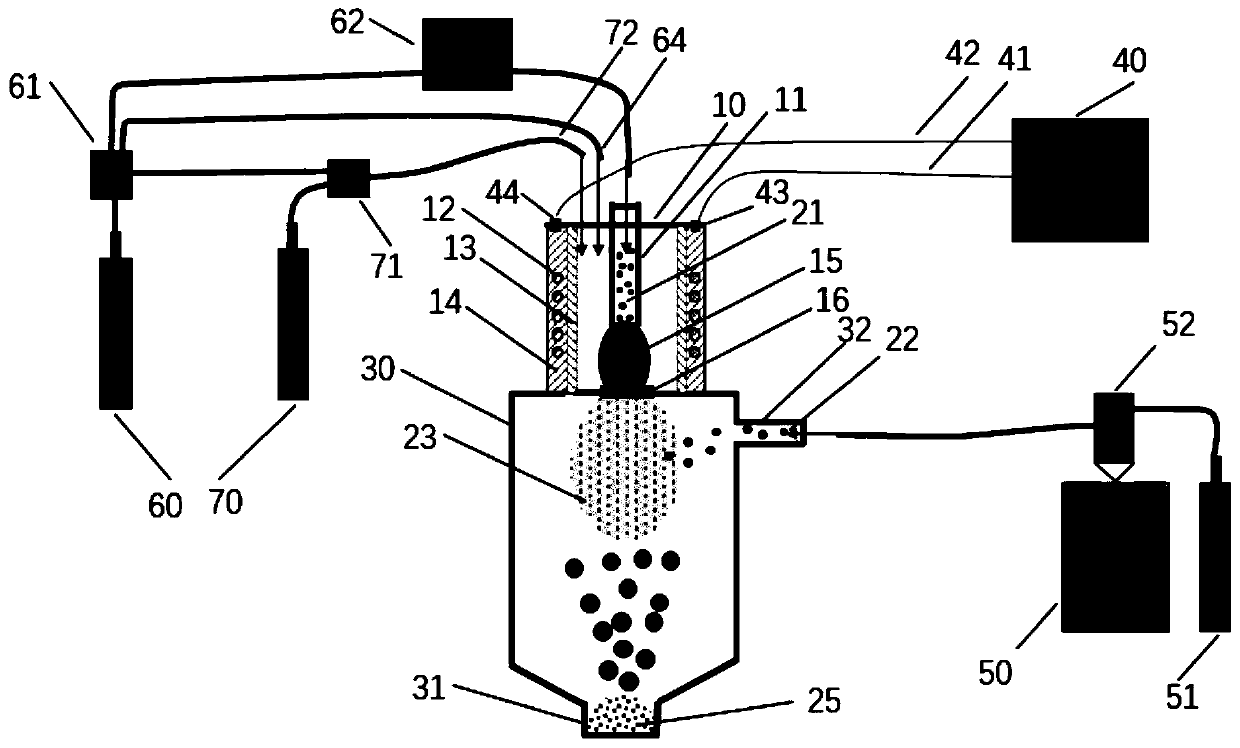

[0101] Example 1 A device for preparing coated powder and its application method

[0102] Such as figure 1 Described coated powder device comprises:

[0103] Plasma torch 10: the plasma torch 10 is used to generate a plasma heat source 15 to melt and / or gasify the powder particles A21. In this embodiment, the plasma torch 10 is an inductively coupled plasma torch. Further, the plasma torch 10 includes a powder feeding probe 11 , an induction coil 12 , a plasma confinement tube 13 and a plasma torch wall 14 .

[0104] The atomizing nozzle 16 ; the atomizing nozzle 16 communicates with the plasma torch 10 and is used to make the melted and / or gasified powder particles A21 form a metal jet 23 .

[0105] The first powder feeder 62 : the first powder feeder 62 communicates with the plasma torch 10 and is used to deliver the powder particles A21 to the plasma torch 10 . Further, the first powder feeder 62 is in fluid connection with the powder feeding probe 11 . The first powde...

Embodiment 2

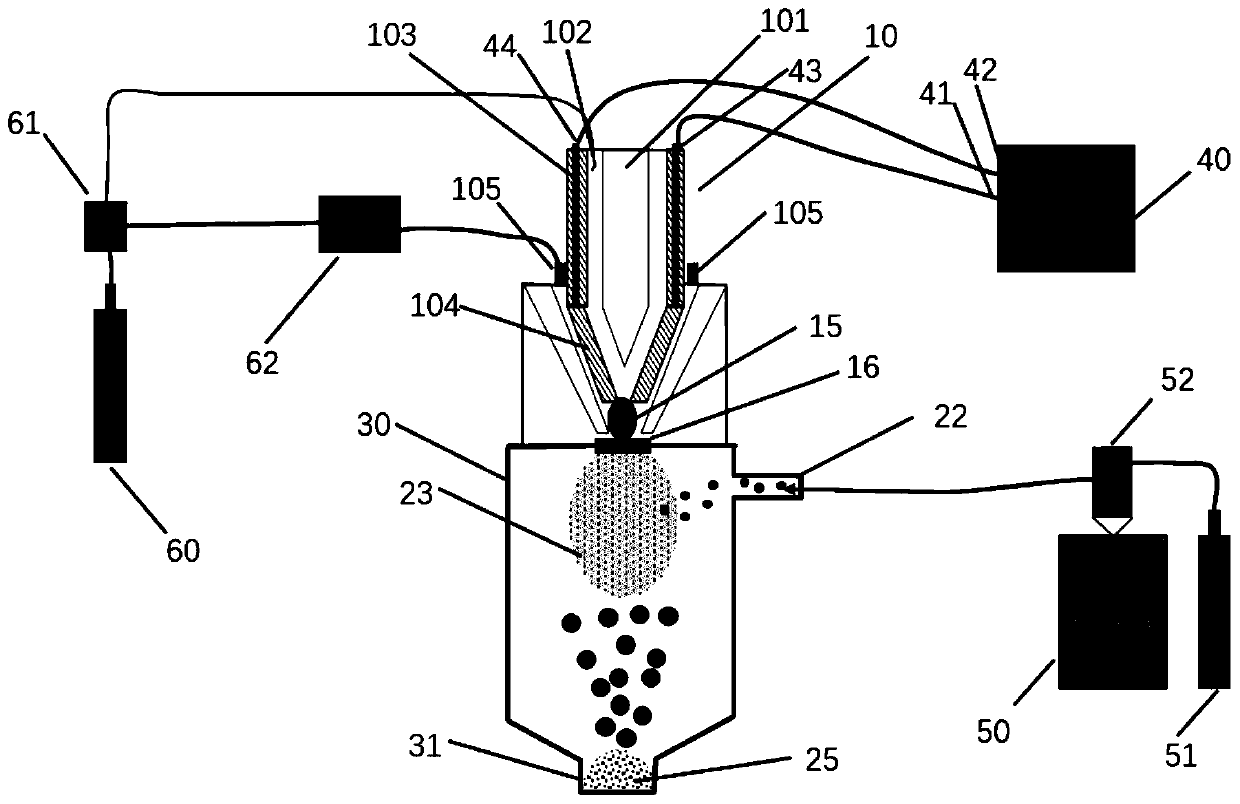

[0121] Example 2 A device for preparing coated powder and its use method

[0122] Such as figure 2 Described coated powder device comprises:

[0123] Plasma torch 10: the plasma torch 10 is used to generate heat source plasma 15 to melt and / or gasify powder particles A. In this embodiment, the plasma torch 10 is a direct current plasma torch. The DC plasma spray gun includes: a tungsten electrode 101 , a central gas channel 102 , a gun body 104 , a built-in cooling water pipe 103 , and a powder feeding channel 105 . The tungsten electrode 101 is installed in the center of the gun body, the tungsten electrode 101 is connected to the negative pole of the power supply, and the gun body is connected to the positive pole of the power supply, a breakdown voltage is generated between the tip of the tungsten electrode and the lower end of the gun body, and the inert gas is broken down to generate a plasma heat source. The central gas channel 102 surrounds the tungsten electrode an...

Embodiment 3

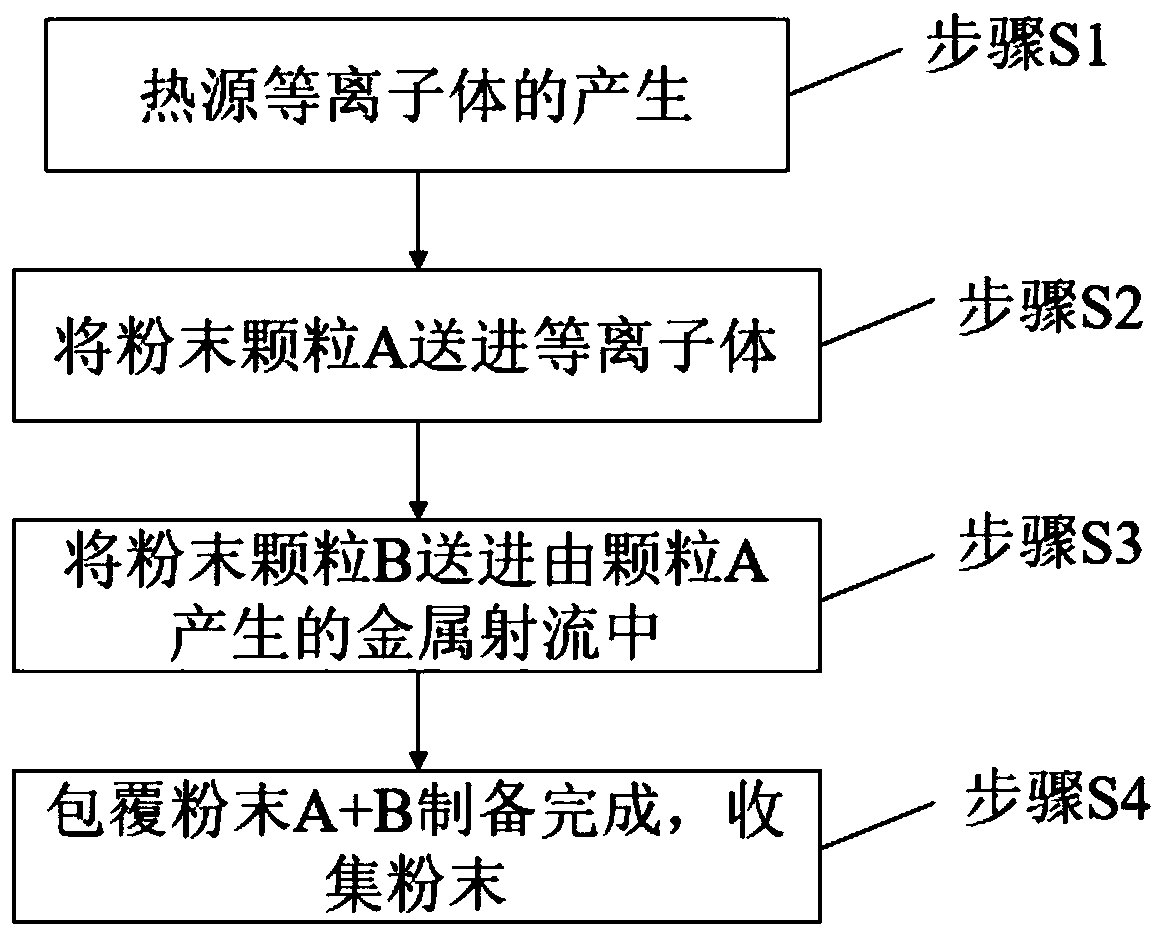

[0140] Embodiment 3 A kind of method for preparing coating powder

[0141] The heat source selects the inductively coupled plasma heat source as the heat source to heat the powder particles A so that they are directly vaporized from the solid particles to the metal jet. Nickel-based alloy powder Ni60 is selected as powder particle A with a particle size of 5-75 μm; hard phase tungsten carbide is selected as powder particle B with a particle size of 15-120 μm and the powder shape is spherical to prepare nickel alloy coated tungsten carbide coating powder .

[0142] Other parameters are as follows: flow rate of central gas argon: 10L / min; power of induction coil: 10KW; ratio of mixed gas: argon / hydrogen = 30L / min: 4L / min; powder feeding rate of powder particle A: 8g / min ; Powder feeding rate of powder particle B: 15g / min; The feeding direction of powder particle B and the feeding direction of powder particle A are at an angle of 90 degrees. The appearance of the prepared coate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com