A method of increasing the crystallization density of the perovskite absorber layer of solar cells

A technology of solar cells and crystal density, applied in circuits, electrical components, photovoltaic power generation, etc., can solve problems such as poly-grain boundary voids, and achieve the effect of reducing voids, improving effective transfer, and compact and dense grain arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

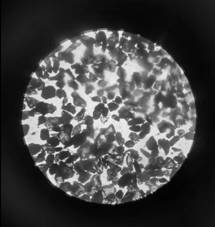

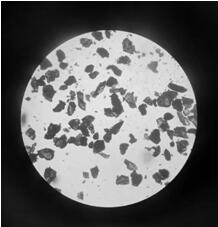

Image

Examples

Embodiment 1

[0038] Step 1: Mix polypropylene resin and acrylic acid grafted polypropylene according to the weight ratio of 100 parts by weight: 15 parts by weight, melt and plasticize the uniformly mixed mixture through an extrusion system, and cast to form a 0.6mm thick base film, After heat treatment, the base film is heated to 110°C and stretched, and the stretched base film is stretched 3 times in the longitudinal direction; the cooling rate is 25°C / min to obtain a heat-shrinkable film, and the heat-shrinkable film is laid flat On the surface of alumina ceramic substrate;

[0039] Step 2: Dissolve 10 parts by weight of methylamine iodine and 30 parts by weight of lead iodide in 100 parts by weight of DMF solvent to prepare a perovskite precursor solution, spin the precursor at a rotation rate of 1000r / min, and spin coating for 30s On the heat-shrinkable film; after drying at 40°C, use a mold to compact the formed film and keep the pressure at 5.5MPa;

[0040] Step 3: After annealing ...

Embodiment 2

[0043] Step 1: Mix polypropylene resin and acrylic acid grafted polypropylene according to the weight ratio of 100 parts by weight: 15 parts by weight, melt and plasticize the uniformly mixed mixture through an extrusion system, and cast to form a 0.6mm thick base film, After heat treatment, the base film is heated to 120°C and stretched, and the stretched base film is stretched 4 times in the longitudinal direction; the cooling rate is 15°C / min to obtain a heat-shrinkable film, and the heat-shrinkable film is laid flat On the surface of alumina ceramic substrate;

[0044] Step 2: Dissolve 10 parts by weight of methylamine iodine and 30 parts by weight of lead iodide in 100 parts by weight of DMF solvent to prepare a perovskite precursor solution, spin the precursor at a rotation rate of 1500r / min, and spin coating for 30s On the heat-shrinkable film; after drying at 45°C, use a mold to compact the formed film and keep the pressure at 6MPa;

[0045] Step 3: After annealing th...

Embodiment 3

[0048] Step 1: Mix polypropylene resin and acrylic acid grafted polypropylene according to the weight ratio of 100 parts by weight: 15 parts by weight, melt and plasticize the uniformly mixed mixture through an extrusion system, and cast to form a 0.6mm thick base film, After heat treatment, the base film is heated to 130°C and stretched, and the stretched base film is stretched 5 times in the longitudinal direction; the cooling rate is 35°C / min to obtain a heat-shrinkable film, and the heat-shrinkable film is laid flat On the surface of alumina ceramic substrate;

[0049] Step 2: Dissolve 10 parts by weight of methylamine iodine and 30 parts by weight of lead iodide in 100 parts by weight of DMF solvent to prepare a perovskite precursor solution, spin the precursor at a rotation rate of 3000r / min, and spin coating for 30s On the heat-shrinkable film; after drying at 60°C, use a mold to compact the formed film and keep the pressure at 5.5MPa;

[0050] Step 3: After annealing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com