Method for preparing back fully-passivated contact solar cell by utilizing tubular PECVD and back fully-passivated contact solar cell

A solar cell, backside technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of increasing production costs, long process time, reducing battery production capacity, etc., to achieve the effects of saving production costs, operating safety, and reducing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

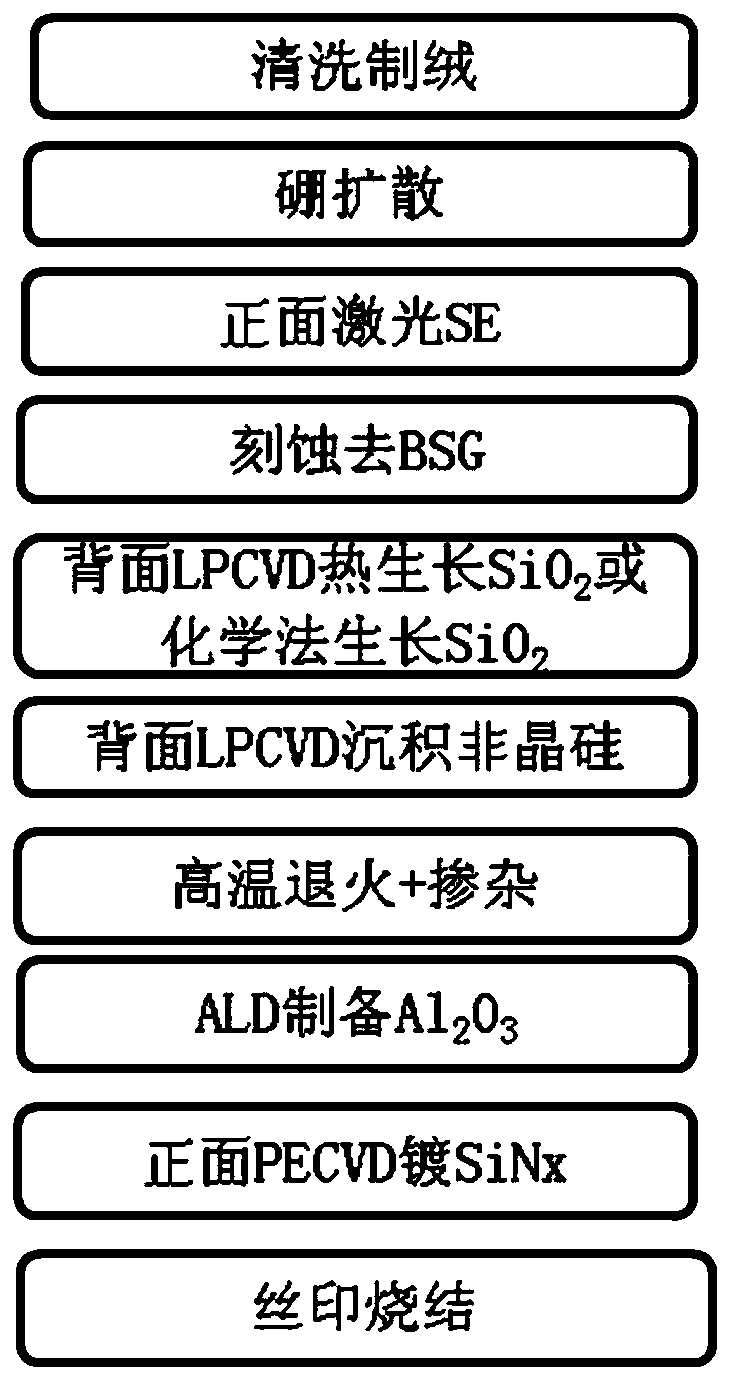

[0046] A kind of method that utilizes tubular PECVD to prepare fully passivated contact solar cell on the back, its preparation process flow chart is as follows image 3 shown, including the following steps:

[0047] (1) Pre-clean silicon wafers (specifically, N-type single crystal silicon wafers with a resistivity of 1Ω·cm~3Ω·cm) in a tank machine to remove the damaged layer, where the solution is potassium hydroxide (KOH) and hydrogen peroxide (H 2 o 2 ) mixed aqueous solution, the potassium hydroxide (KOH) and hydrogen peroxide (H 2 o 2 ) mixed aqueous solution is obtained by mixing potassium hydroxide solution and hydrogen peroxide solution, wherein the volume ratio of potassium hydroxide solution and hydrogen peroxide solution is 1:3, and the mass concentration of potassium hydroxide solution is 45%, and the mass concentration of hydrogen peroxide solution is 30%. In this step, pre-cleaning is performed at a temperature of 60° C. for 160 s.

[0048] (2) Carry out dou...

Embodiment 2

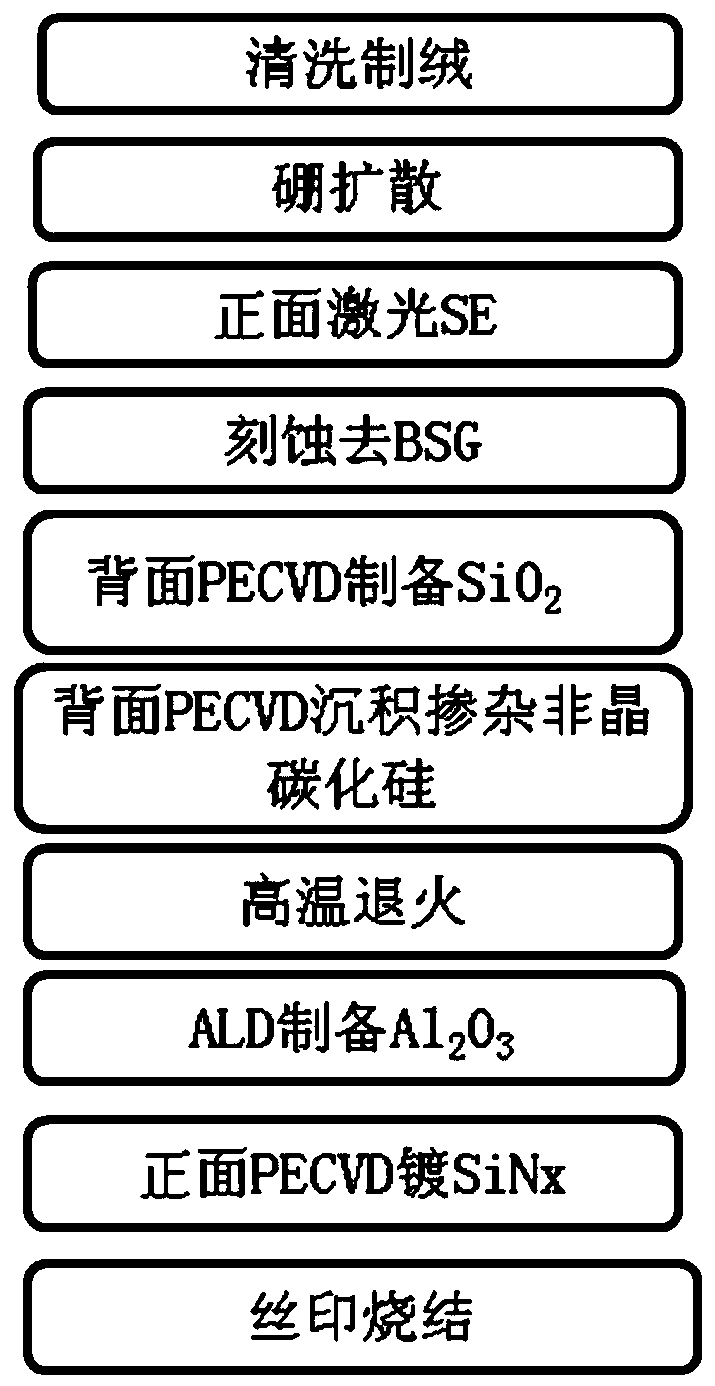

[0066] A kind of method that utilizes tubular PECVD to prepare fully passivated contact solar cell on the back side, comprises the following steps:

[0067] (1) Pre-clean silicon wafers (specifically, N-type single crystal silicon wafers with a resistivity of 1Ω·cm~3Ω·cm) in a tank machine to remove the damaged layer, where the solution is potassium hydroxide (KOH) and hydrogen peroxide (H 2 o 2 ) mixed aqueous solution, the potassium hydroxide (KOH) and hydrogen peroxide (H 2 o 2 ) mixed aqueous solution is obtained by mixing potassium hydroxide solution and hydrogen peroxide solution, wherein the volume ratio of potassium hydroxide solution and hydrogen peroxide solution is 1:3, and the mass concentration of potassium hydroxide solution is 45%, and the mass concentration of hydrogen peroxide solution is 30%. In this step, pre-cleaning is performed at a temperature of 60° C. for 160 s.

[0068] (2) double-sided texturing is carried out to the silicon chip after pre-cleani...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com