High-yield high-strength electroplating PC/ABS alloy and preparation method thereof

A high-yield, high-strength technology, applied in the field of high-yield and high-strength electroplating PC/ABS alloys and their preparation, can solve problems such as increasing production costs and increasing the difficulty of process operations, and achieves enhanced bonding force, easy promotion, The effect of good electroplating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment provides a high-yield high-strength electroplated PC / ABS alloy product, including the following components in parts by weight:

[0042] PC 80 copies

[0043] ABS resin 15 parts

[0044] Polybutylacrylate 5 parts

[0045] Antioxidant 1010 0.4 parts

[0046] 0.5 parts of stearic acid amide;

[0047] The electroplated PC / ABS alloy product of the present embodiment is made by following method:

[0048] (1) Mixing: Weigh the raw materials according to the above parts by weight, add ABS resin, polybutylacrylate, antioxidant 1010, and stearic acid amide into a high-speed mixer and mix for 2 minutes to obtain a premix;

[0049] (2) Extrusion granulation: Add the premix into the barrel of the twin-screw extruder through the feeding device, set the pressure to -0.1MPa, the screw speed to 300r / min, and set the temperature of the barrel of the extruder to 5 The sections are 190°C-210°C-230°C-240°C-240°C in sequence. First, melt and plasticize evenly in the firs...

Embodiment 2-9

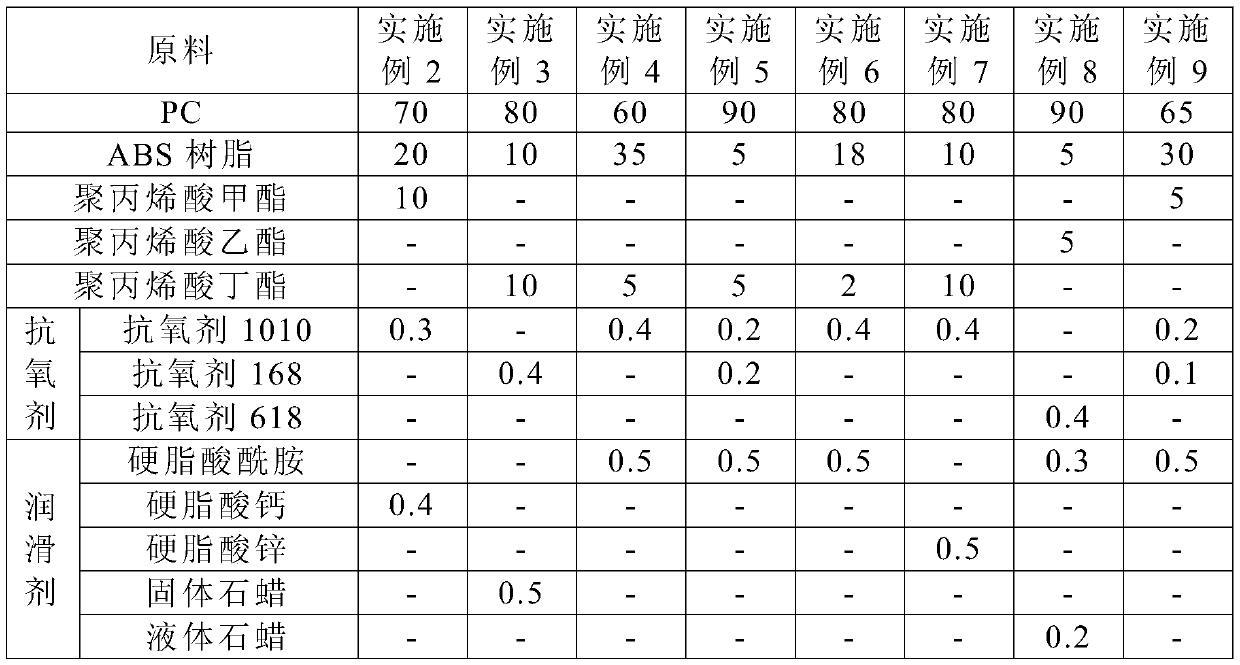

[0052] The only difference between Examples 2-9 and Example 1 is that the raw materials or proportions of electroplated PC / ABS alloy products are different. The raw material components and proportions of Examples 2-9 are shown in Table 1.

[0053] The raw material component distribution ratio of table 1 embodiment 2-9

[0054]

Embodiment 10

[0056] The difference between this example and Example 1 is that the five temperature zones in the extrusion granulation process are respectively set to 180°C-200°C-230°C-240°C-250°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap